In this article, we’ll break down the technical principles behind the 14.8V lithium battery, analyze how it enhances robot performance, and explore its core advantages and real-world applications. We’ll also guide you on how to choose the right 14.8V lithium battery for your robot. Whether you’re a robotics developer or a casual user, this guide has everything you need. Let’s dive in and see how a 14.8V lithium battery can take your robot’s performance to the next level!

Understanding the 14.8V Lithium Battery: Technology and Robotics Applications

How Does a 14.8V Lithium Battery Work?

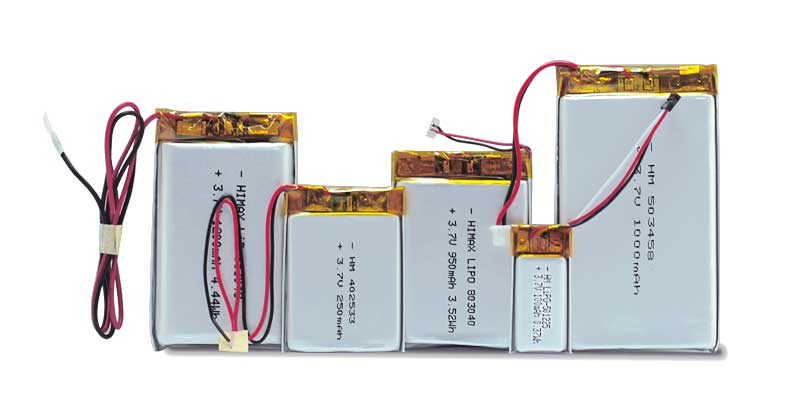

A 14.8V lithium battery is a rechargeable power source based on lithium-ion technology. Its core mechanism involves the movement of lithium ions between the positive and negative electrodes to store and release energy. Typically, these batteries are made up of multiple single cells connected in series. Each cell has a nominal voltage of 3.7V, so a 14.8V battery consists of four cells (known as a 4S configuration). This voltage level is perfectly suited for the power and endurance needs of robots, providing a steady energy output.

The positive electrode in lithium batteries is often made of materials like lithium iron phosphate or ternary compounds, while the negative electrode is usually graphite. An electrolyte facilitates the movement of lithium ions. During discharge, lithium ions travel from the negative to the positive electrode, generating a current; during charging, the ions move in the opposite direction. This efficient charge-discharge cycle makes the 14.8V lithium battery a standout performer in robotics, capable of supporting long runtimes and high-power demands.

How Does a Lithium Battery Improve Robot Performance?

The 14.8V lithium battery enhances robot performance in several key ways. First, its high energy density allows it to store more energy in a smaller size or weight compared to other battery types, giving robots longer runtimes. For example, a 14.8V, 4500mAh lithium battery can power a robotic vacuum for over two hours—far surpassing the capabilities of traditional nickel-metal hydride batteries.

Second, the 14.8V lithium battery offers excellent discharge efficiency, supporting high current output to meet the power demands of complex robotic movements. Industrial robots, for instance, often need to move quickly or lift heavy objects, and a 14.8V lithium battery provides the consistent high power needed for smooth, precise actions. Plus, lithium batteries have a low self-discharge rate (only 2-3% per month), meaning they retain their charge even during long periods of inactivity, reducing energy waste and keeping robots ready to go.

Core Advantages of a 14.8V Lithium Battery

Advantage 1: Lightweight Design for Greater Robot Agility

Compared to traditional lead-acid batteries, a 14.8V lithium battery is significantly lighter. A lead-acid battery weighs about 30-50 kg per kilowatt-hour, while a lithium battery weighs just 10-15 kg—a reduction of nearly 50%. This lightweight design is a game-changer for robots, especially those that need to move frequently, like household or service robots. A lighter battery improves a robot’s maneuverability and reduces energy consumption.

For example, a household robotic vacuum equipped with a 14.8V lithium battery is much lighter, making it easier to navigate around furniture and tackle tricky terrain, ultimately boosting cleaning efficiency. For robots that require high mobility, this lightweight design not only enhances performance but also extends their operational lifespan.

Advantage 2: Long Cycle Life to Cut Maintenance Costs

One of the standout features of a 14.8V lithium battery is its impressive cycle life. High-quality lithium batteries can handle over 2,000 charge-discharge cycles, which translates to 5-6 years of daily use—far outlasting lead-acid batteries, which typically manage only 300-500 cycles. This means robot users don’t have to replace batteries as often, significantly lowering maintenance costs.

For industrial robots, a long-lasting 14.8V lithium battery is especially valuable. In industrial settings, robots often need to operate around the clock, and battery durability directly impacts productivity. Choosing a lithium battery with a high cycle life reduces downtime and saves businesses money on long-term operational expenses.

Advantage 3: High Safety for Reliable Robot Operation

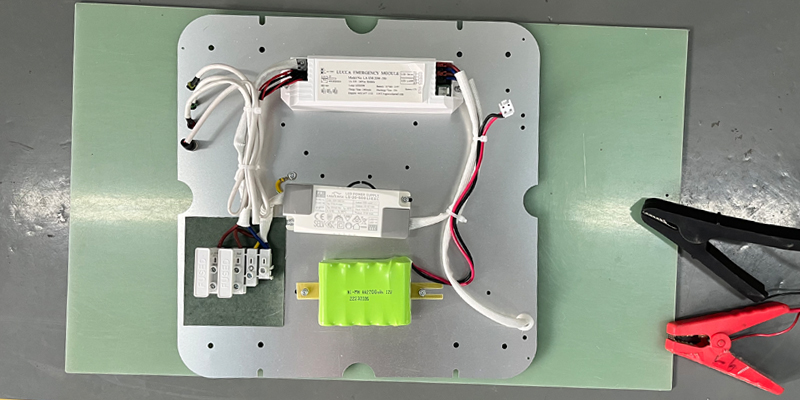

Safety is another major advantage of the 14.8V lithium battery. Modern lithium batteries come with a built-in Battery Management System (BMS) that monitors the battery’s status in real time, preventing issues like overcharging, over-discharging, and short circuits. The BMS also balances the voltage across individual cells, ensuring the battery pack operates smoothly. This design is perfect for the demanding conditions robots often face.

Additionally, 14.8V lithium batteries offer superior thermal stability compared to other battery types, making them less prone to overheating or catching fire, even in high temperatures or extreme conditions. This is crucial for industrial robots operating in hot factory environments. A safe, reliable battery ensures consistent robot performance while minimizing risks for users.

Real-World Performance: 14.8V Lithium Batteries in Robotics

Household Service Robots

In home settings, 14.8V lithium batteries are widely used in devices like robotic vacuums and smart speaker robots. Take a robotic vacuum, for example: a 14.8V, 2200mAh lithium battery can keep it running for 90-120 minutes, covering over 2,000 square feet. Compared to traditional nickel-metal hydride batteries, lithium batteries charge faster (typically in 2-3 hours) and offer longer runtimes, greatly improving the user experience.

What’s more, the low self-discharge rate of a 14.8V lithium battery means it holds its charge even when the robot isn’t in use for a while, keeping it ready for action. This is a huge plus for household service robots, eliminating the hassle of frequent recharging.

Industrial Robots

In industrial applications, 14.8V lithium batteries power material-handling robots, welding robots, and more. These robots often require high power output for fast movements or precise tasks, and a 14.8V lithium battery delivers the steady current needed for efficient operation. For instance, a material-handling robot with a 14.8V, 4500mAh lithium battery can work continuously for over six hours, meeting the demands of round-the-clock factory production.

The high safety features of 14.8V lithium batteries also make them ideal for industrial environments. The built-in BMS prevents overheating and short circuits, ensuring robots can operate reliably in high-temperature, high-intensity conditions.

How to Choose the Right 14.8V Lithium Battery for Your Robot

Capacity and Power Requirements

When selecting a 14.8V lithium battery, start by determining the capacity based on your robot’s type and power needs. A household robotic vacuum typically requires a 2200mAh-3000mAh battery for daily cleaning, while an industrial material-handling robot might need a 4500mAh or higher capacity battery to support extended high-power operation. Before buying, check your robot’s power specifications to ensure the battery capacity matches.

Also, pay attention to the battery’s discharge rate (C-rate). High-rate batteries (like 20C) are better for robots needing bursts of high current, while low-rate batteries (like 5C) suit robots with steady power demands.

Safety and Certifications

Safety is a critical factor when choosing a 14.8V lithium battery. High-quality batteries should carry certifications like CE and RoHS, ensuring they meet safety and environmental standards. Additionally, check if the battery includes a BMS, which helps prevent overcharging, over-discharging, and other issues, extending the battery’s lifespan. Always opt for brands with clear safety certifications to avoid performance issues or robot malfunctions.

Brand and After-Sales Support

Choosing a reputable brand with solid after-sales support is just as important. Top brands often provide detailed technical support and warranty policies. For example, HIMAX Electronics is known for its professional battery solutions and offers a one-year warranty that customers trust. When shopping, read user reviews to gauge real-world performance, and confirm that the seller provides installation guidance and customer support.

Discover HIMAX’s 14.8V Lithium Batteries for Your Robot

A 14.8V lithium battery offers lightweight design, long cycle life, and high safety, making it a powerful ally in boosting robot performance. It extends runtime, enhances efficiency, and ensures stability across a range of applications—from household service robots to industrial machines.

Looking for a high-performance battery for your robot? HIMAX Electronics’ 14.8V lithium battery lineup is the perfect choice. With various capacity options (like 2200mAh and 4500mAh) and advanced BMS technology, our batteries guarantee safety and durability. Visit the HIMAX website to explore the ideal battery solution for your robot today!