A research team has developed a core technology to ensure the charging/discharging stability and long-life of lithium-ion batteries under fast-charging conditions. Their findings were published in Advanced Functional Materials.

A crucial prerequisite for the widespread adoption of electric vehicles (EVs) is the enhancement of lithium-ion battery performance in terms of driving range and safety. Fast charging is also essential for user convenience. However, increasing the energy density of lithium-ion batteries necessitates thicker electrodes, which can lead to battery degradation and performance deterioration during rapid charging.

To address this issue, the KERI team discovered a solution by partially coating the surface of the anode of the lithium-ion battery with aluminum oxide (Al2O3) particles smaller than 1 micrometer. While many researchers worldwide have concentrated on the materials within the electrode, such as introducing functional nanotechnology into anode materials like graphite, Dr. Choi’s team employed a straightforward processing technique to coat the electrode’s surface with aluminum oxide.

Low in cost, excellent in electrical insulation and heat resistance, chemically stable, and possessing good mechanical properties, aluminum oxide is widely used in various ceramics.

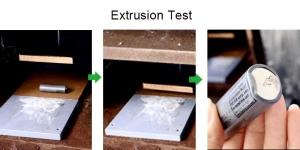

The KERI researchers found that aluminum oxide particles effectively control the interface between the anode and the electrolyte in lithium-ion batteries, forming an interfacial highway for efficient Li+ transport. This prevents the electrodeposition of lithium (an irreversible change that makes the lithium unavailable for additional charging and discharging) during fast charging, thereby ensuring the stability and lifespan of the lithium-ion battery during charging and discharging.

Another advantage of this technology is that it enables an increase in the energy density of lithium-ion batteries. Introducing other functional materials into the electrode’s interior to improve performance and stability often complicates the synthesis process and reduces the amount of reversible lithium (initial coulombic efficiency). It also increases the electrode thickness, leading to performance deterioration under fast charging conditions.

However, the KERI technology involves surface treatment of the graphite anode, rather than modifying the interior active graphite materials. This approach achieves stable performance even under fast charging conditions for high-energy-density thick-film electrodes without a loss in the amount of reversible lithium.

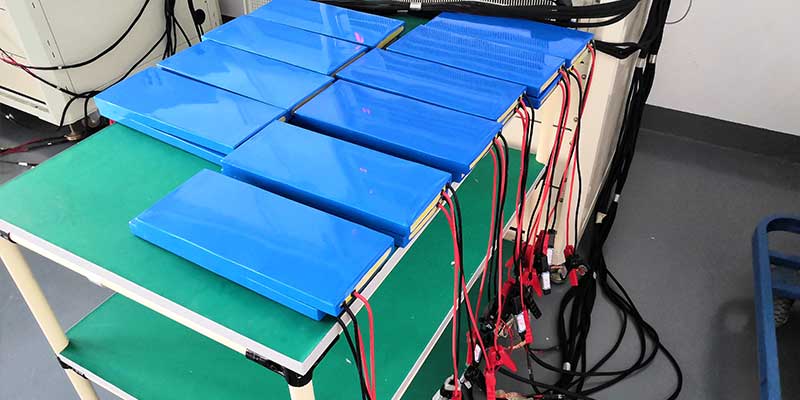

Through various tests, the team confirmed that the high-energy-density anode coated with aluminum oxide (4.4 mAh/cm2) exhibits world-class performance, maintaining more than 83.4% of its capacity (residual capacity ratio) even after 500 cycles of rapid charging. They have verified this performance with pouch cells of up to 500mAh. The team is now planning to scale up the technology to make it applicable to large-area, medium- to large-capacity cells.

The research team was led by Dr. Choi Jeong Hee at the Korea Electrotechnology Research Institute (KERI) Battery Materials and Process Research Center, in cooperation with a Hanyang University team mentored by Professor Lee Jong-Won and a Kyunghee University team mentored by Professor Park Min-Sik.

“Convenient fast charging and the energy density of lithium-ion batteries have long been considered a trade-off, which has hindered the widespread adoption of electric vehicles,” said Dr. Choi. “Our work will help develop stable, high-energy-density lithium batteries capable of fast charging. This advancement will contribute to the wider adoption of EVs and support the achievement of national carbon neutrality.”

Patents have been registered in both Korea and the United States.

More information: Jeong‐Hee Choi et al, Multi‐Interface Strategy for Electrode Tailoring Toward Fast‐Charging Lithium‐Ion Batteries, Advanced Functional Materials (2024). DOI: 10.1002/adfm.202400414