Understanding NiMH Battery:

Comprehensive Guide

Nickel-metal hydride (NiMH) batteries have been a staple in the rechargeable battery market for decades, known for their robust performance and environmental friendliness. Whether you’re using handheld devices, electric vehicles, or need reliable power for any number of applications, understanding NiMH technology can help you make informed decisions. This guide provides an in-depth look at NiMH batteries, from their basic chemistry and advantages to their common applications and why Himax Electronics is a trusted provider of these battery solutions.

What is a NiMH Battery?

A NiMH battery is a type of rechargeable battery that uses a hydrogen-absorbing alloy for the anode and nickel oxide hydroxide for the cathode. A key feature of NiMH batteries is their ability to offer higher energy density compared to older battery types like nickel-cadmium (NiCd).

Key Components of NiMH Batteries

- Cathode: Composed of nickel oxide hydroxide, which acts as the positive electrode.

- Anode: Made from a hydrogen-absorbing alloy, serving as the negative electrode.

- Electrolyte: Typically potassium hydroxide (KOH), facilitating ion transfer between the cathode and anode.

- Separator: A non-conductive film that prevents direct contact between the cathode and anode while allowing ion exchange.

How NiMH Batteries Work

NiMH batteries operate on the principle of rapid ion exchange:

- Charging: During charging, electrical energy from the charger converts nickel oxide into nickel and the hydrogen-absorbing alloy forms a hydride.

- Discharging: During use, the process reverses; nickel gives up its electrons, and the metal hydride releases hydrogen ions which recombine to form water, releasing electrical energy in the process.

Advantages of NiMH Batteries

- Energy Density: NiMH batteries typically have a higher energy density than NiCd batteries, providing longer run times.

- Environmental Impact: They are more environmentally friendly than NiCd batteries, as they do not contain toxic cadmium.

- Reduced Memory Effect: While NiMH batteries can experience memory effect, it is less pronounced than in NiCd batteries, making them more suitable for a wide range of applications.

- Versatility: NiMH batteries can be used in a wide array of devices, from small household items to larger automotive applications.

Applications of NiMH Batteries

- Consumer Electronics: Ideal for digital cameras, portable audio players, and other portable gadgets due to their robust energy output.

- Electric Vehicles: Used in some hybrid vehicles because of their good capacity and environmental safety.

- Medical Devices: Reliable for medical devices that require consistent and safe battery performance.

- Power Tools: Commonly used in cordless power tools for their ability to handle high drains with minimal performance loss.

Choosing Himax Electronics for NiMH Batteries

Opting for Himax Electronics for your NiMH battery needs offers numerous advantages:

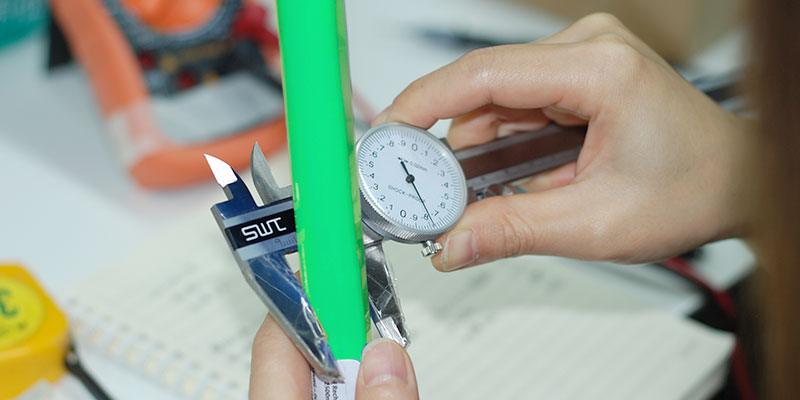

- High-Quality Products: We provide top-tier NiMH batteries that meet rigorous testing and quality standards.

- Custom Solutions: Himax Electronics can tailor battery solutions to meet specific application needs, ensuring optimal performance and integration.

- Sustainable Practices: We are committed to sustainable production practices, minimizing environmental impact while delivering high-performance products.

- Expert Support: Our team offers expert advice and comprehensive support, helping you maximize the efficiency and lifespan of your NiMH batteries.

Conclusion

Nickel-metal hydride batteries offer a reliable and eco-friendly power solution for a wide array of applications. With their balance of capacity, durability, and environmental benefits, NiMH batteries continue to be a preferred choice for both consumers and industries. By choosing Himax Electronics, you gain access to superior battery technology backed by expert service and support, ensuring your energy solutions are effective, efficient, and environmentally responsible.