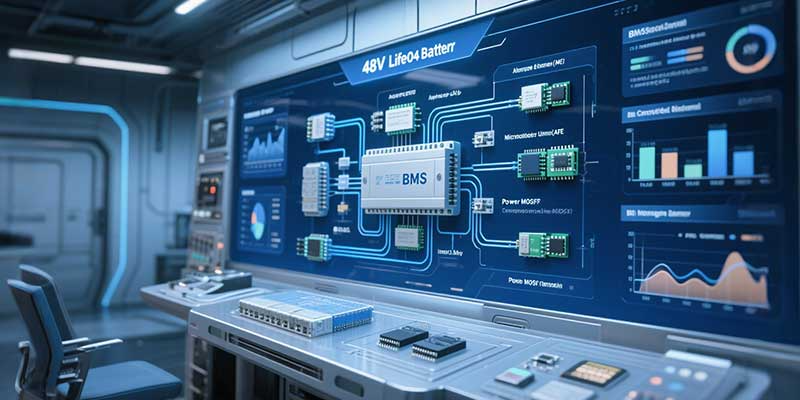

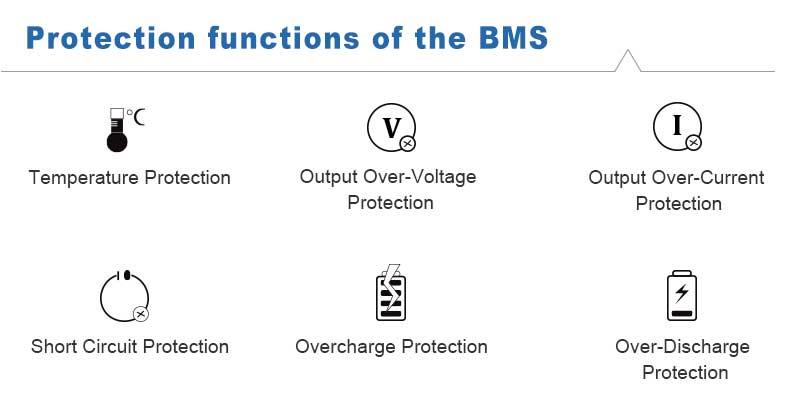

Modern lithium battery systems rely heavily on communication interfaces to monitor status, ensure safety, and exchange data with host devices. A Battery Management System (BMS) acts as the “brain” of a lithium battery pack, and communication protocols are the language it uses to talk with chargers, controllers, computers, and user interfaces.

This article explains RS232, RS485, I²C, and SMBus communication protocols and how each is commonly applied in lithium battery BMS systems.

1.RS232 Communication

What is RS232?

RS232 is one of the oldest and simplest serial communication standards. It is a point-to-point, single-ended communication method that transmits data using voltage levels.

Key characteristics:

- Point-to-point communication (one device to one device)

- Short communication distance (typically <15 meters)

- Relatively low noise immunity

- Simple wiring (TX, RX, GND)

- Baud rates typically up to 115200 bps

RS232 in Lithium Battery BMS

In lithium battery applications, RS232 is mainly used for:

- BMS configuration and debugging

- Factory testing

- PC-to-BMS communication via USB-to-RS232 adapters

Typical data exchanged:

- Cell voltages

- Pack voltage and current

- State of Charge (SOC)

- Temperature readings

- Fault and protection status

- Parameter configuration (over-voltage, over-current, etc.)

Advantages for BMS:

- Easy to implement

- Widely supported by BMS tools

- Low cost

Limitations:

- Not suitable for long distances

- Poor resistance to electrical noise

- Not ideal for industrial or automotive environments

2. RS485 Communication

What is RS485?

RS485 is a differential serial communication standard designed for robust, long-distance, and multi-device communication.

Key characteristics:

- Differential signaling (A/B lines)

- Communication distance up to 1200 meters

- High noise immunity

- Supports multiple devices on the same bus

- Often used with Modbus protocol

RS485 in Lithium Battery BMS

RS485 is widely used in industrial, energy storage, and electric vehicle applications.

Common BMS applications:

- Communication between BMS and inverter

- Battery rack or module networking

- Energy storage systems (ESS)

- Robotics and industrial equipment

Typical data exchanged:

- Real-tme battery status

- Alarm and fault information

- Charge/discharge limits

- SOC / SOH data

Advantages for BMS:

- Long cable distance

- Excellent noise resistance

- Supports multi-battery systems

- Stable in harsh environments

Limitations:

- More complex than RS232

- Requires proper termination and addressing

3. I²C Communication

What is I²C?

I²C (Inter-Integrated Circuit) is a short-distance, low-speed communication protocol designed for communication between chips on the same PCB.

Key characteristics:

- Two-wire interface (SDA, SCL)

- Master-slave architecture

- Short distance (usually <1 meter)

- Low power consumption

I²C in Lithium Battery BMS

I²C is mostly used inside the battery pack, rather than for external communication.

Common BMS applications:

Communication between BMS MCU and:

- Cell monitoring ICs

- Temperature sensors

- EEPROM / memory chips

- Internal data acquisition and control

Advantages for BMS:

- Simple wiring

- Low power consumption

- Ideal for internal electronics

Limitations:

- Not suitable for long distances

- Sensitive to noise

- Not designed for external system communication

4. SMBus Communication

What is SMBus?

SMBus (System Management Bus) is a derivative of I²C, specifically designed for power and battery management applications.

Key characteristics:

- Based on I²C physical layer

- Defined timing and voltage levels

- Standardized command set

- Supports battery management functions

SMBus in Lithium Battery BMS

SMBus is widely used in smart battery systems, especially for consumer electronics and industrial devices.

Common applications:

- Laptop batteries

- Medical devices

- Smart battery packs

- Communication between battery and host system

Typical data exchanged:

- Remaining capacity

- Full charge capacity

- Cycle count

- Battery health (SOH)

- Charging status

- Manufacturer data

Advantages for BMS:

- Industry-standard smart battery protocol

- Plug-and-play compatibility

- Rich battery information support

Limitations:

- Limited communication distance

- Requires host support for SMBus

- Less flexible than custom protocols

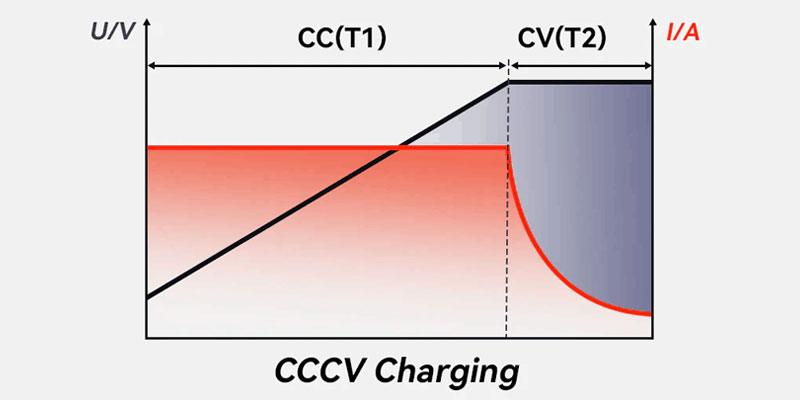

5. Comparison Summary

| Protocol | Distance | Noise Immunity | Typical Use in BMS |

| RS232 | Short | Low | BMS setup, debugging, PC tools |

| RS485 | Long | High | ESS, inverters, industrial systems |

| I²C | Very short | Low | Internal BMS IC communication |

| SMBus | Short | Medium | Smart batteries, host communication |

6. Choosing the Right Communication for a BMS

The choice of communication protocol depends on:

- Application environment(consumer vs industrial)

- Communication distance

- System complexity

- Host device compatibility

- Noise and EMI conditions

Many modern lithium battery systems use multiple protocols simultaneously, for example:

- I²C internally inside the BMS

- RS485 to communicate with an inverter

- RS232 or USB for configuration and service

- SMBus for smart battery applications

Conclusion

RS232, RS485, I²C, and SMBus each play a distinct role in lithium battery BMS communication. Understanding their differences helps system designers and users select the most suitable interface for reliable monitoring, control, and safety.

As lithium battery applications continue to expand in energy storage, robotics, and electric mobility, choosing the right communication protocol is essential for performance, safety, and system integration.