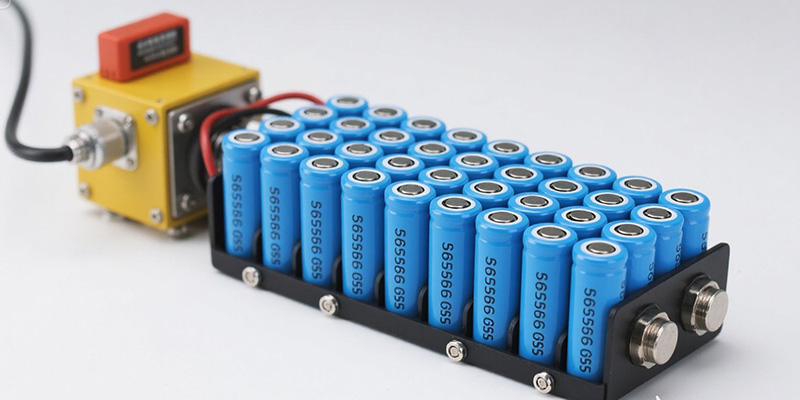

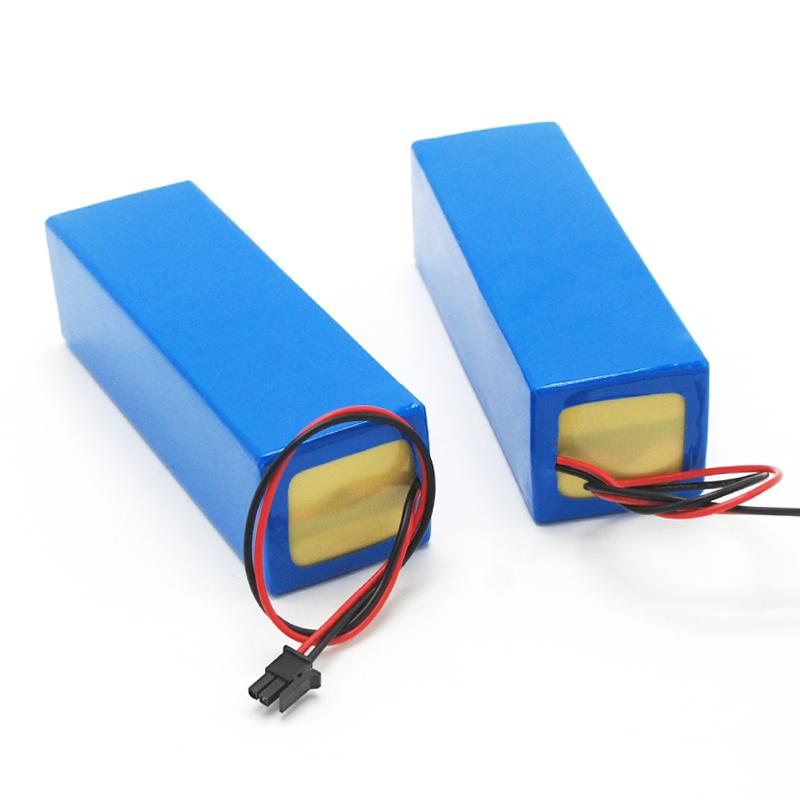

At HIMAX Electronics, we understand that ensuring the maximum efficiency, safety, and lifespan of lithium-ion batteries goes beyond simply using high-quality cells. One critical element in achieving optimal performance is cell balancing. For any system that uses multiple cells, such as electric vehicles (EVs), energy storage systems, and robotics, effective cell balancing is essential to maintain the overall health and performance of the battery pack.

In this article, we will delve into what cell balancing is, why it is necessary, and how it works in lithium-ion batteries, focusing on how HIMAX Electronics employs advanced cell balancing techniques to ensure the longevity and reliability of your battery systems.

What is Cell Balancing?

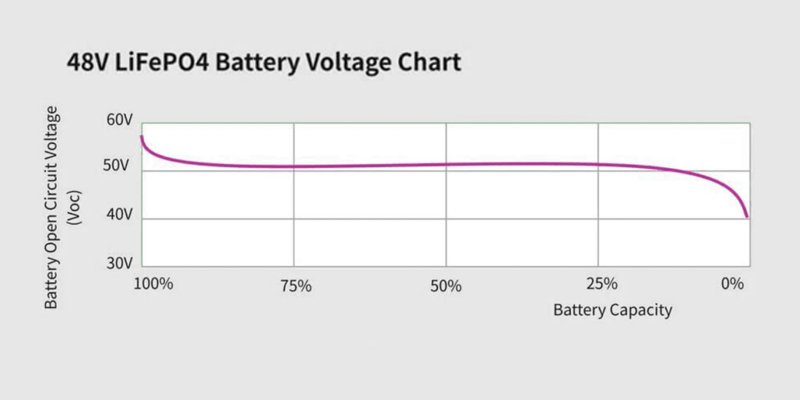

Cell balancing refers to the process of ensuring that all the cells within a battery pack charge and discharge at the same rate, maintaining uniform voltage levels across all cells. In a multi-cell battery pack, some cells can become more charged or discharged than others, leading to imbalances that can reduce the performance and life of the battery.

When cells are not balanced, some cells may reach their maximum voltage while others remain undercharged. This can cause certain cells to age faster, reducing the overall capacity of the battery pack and leading to potential failure. To prevent this, cell balancing ensures that all cells are kept in balance, ensuring uniform voltage, charge, and discharge across the pack.

Why is Cell Balancing Important?

Maximizes Battery Life

Imbalances in a battery pack can cause certain cells to be overcharged or over-discharged, which leads to degradation. This can significantly shorten the lifespan of the entire battery pack. Cell balancing helps to prevent this by ensuring that no cell is overcharged or deeply discharged, ultimately prolonging the battery’s useful life.

Improves Efficiency

A balanced battery pack operates more efficiently. When all cells in the pack are at similar charge levels, the battery can deliver its full capacity without wasting energy on cells that are underperforming. This ensures that the battery operates at its optimal efficiency, which is critical for high-demand applications like electric vehicles and power tools.

Prevents Safety Hazards

Lithium-ion batteries are highly sensitive to voltage extremes. If a cell is overcharged or over-discharged, it can become unstable, leading to potential safety hazards like thermal runaway, which can cause fires or explosions. Effective cell balancing reduces these risks by keeping the battery pack within safe voltage limits.

Ensures Reliable Performance

In applications where reliability is paramount, such as in medical devices, drones, or uninterruptible power supplies (UPS), having a balanced battery pack ensures that the system performs predictably over time. Cell imbalances can lead to unpredictable behavior, reduced power output, or unexpected shutdowns, especially when one or more cells are undercharged or overcharged.

How Does Cell Balancing Work?

There are two main types of cell balancing: passive balancing and active balancing. Both methods aim to ensure that all cells in the pack remain within a safe and optimal voltage range, but they work in different ways.

-

Passive Balancing

Passive balancing is the more traditional and widely used method for balancing battery cells. In this process, excess energy from the more charged cells is dissipated as heat. Essentially, the system “burns off” the excess voltage from the cells that are overcharged to bring them in line with the cells that are undercharged. The energy from the higher-voltage cells is typically dissipated using resistors.

Advantages of Passive Balancing:

Simple design: It’s relatively inexpensive and easy to implement.

Low complexity: Suitable for most applications that don’t require extreme precision.

Disadvantages:

Energy loss: The energy from the higher-voltage cells is wasted as heat, which can result in lower overall efficiency.

Slower balancing process: It’s less efficient than active balancing in terms of speed and energy conservation.

-

Active Balancing

Active balancing, on the other hand, is a more sophisticated method that redistributes excess energy from higher-voltage cells to lower-voltage ones, rather than dissipating it as heat. This method usually involves specialized circuits that either transfer energy from high-voltage cells to low-voltage ones or store it temporarily to be used later.

Advantages of Active Balancing:

Energy-efficient: Active balancing redistributes energy, reducing waste and improving overall battery efficiency.

Faster and more precise: This method can achieve better cell matching, as it redistributes energy more quickly and evenly.

Long-term cost savings: While active balancing systems can be more expensive initially, their energy efficiency and ability to extend battery life make them cost-effective in the long run.

Disadvantages:

Higher cost: The complexity of active balancing circuits means that it is more expensive than passive balancing.

Complexity: Active balancing requires more sophisticated design and components.

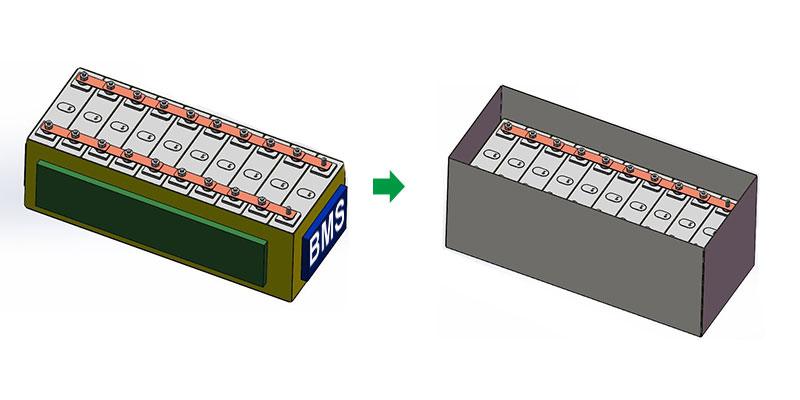

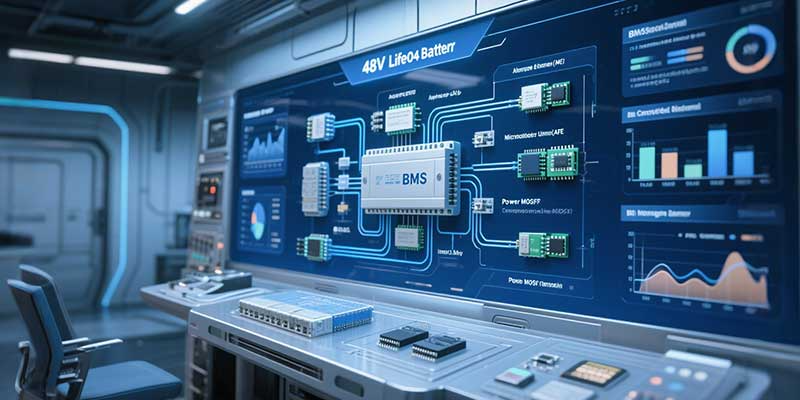

How HIMAX Electronics Ensures Optimal Cell Balancing

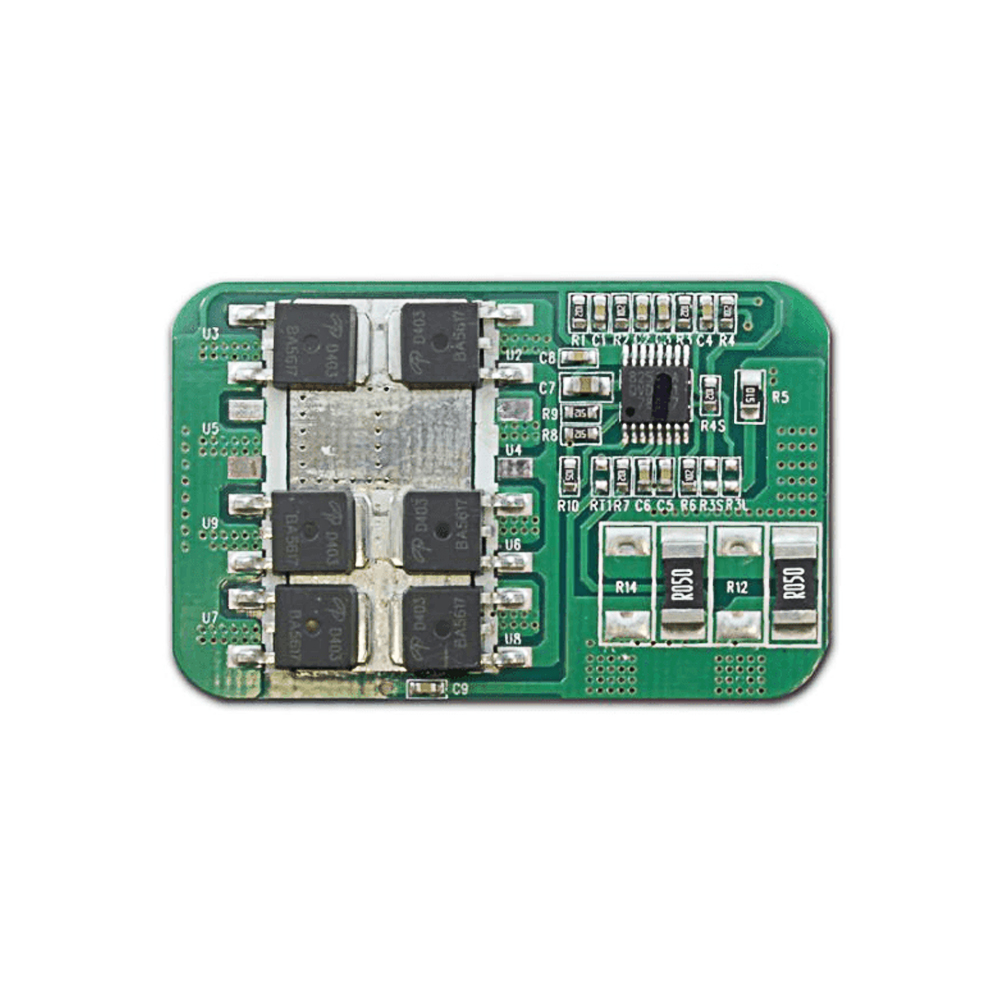

At HIMAX Electronics, we understand that the performance, safety, and lifespan of lithium-ion battery packs depend heavily on the proper balancing of cells. To achieve the best results, we use advanced BMS (Battery Management Systems) that incorporate both passive and active cell balancing techniques, tailored to the specific needs of each application.

Custom Solutions: We design BMS systems that are specifically tailored to your battery pack’s voltage, current, and power requirements. Our cell balancing solutions are optimized for your application, whether it’s a high-performance electric vehicle, solar energy storage, or industrial robots.

Cutting-edge Technology: We use the latest in cell balancing technology to ensure that all cells are kept within safe operating limits. By integrating active balancing systems into high-performance applications, we can ensure that energy is conserved, battery performance is maximized, and the system operates at peak efficiency.

Comprehensive Safety Features: Our BMS systems are designed with safety in mind. By balancing cells effectively, we prevent overcharging and overheating, which can lead to thermal runaway and other safety hazards. We also provide continuous monitoring of cell voltage, temperature, and current to provide real-time diagnostics and alerts.

Applications of Cell Balancing

The importance of cell balancing extends to a wide variety of applications, including:

Electric Vehicles (EVs): In EVs, cell balancing ensures that the battery pack operates efficiently and has a longer lifespan, which is crucial for extending the vehicle’s range and reducing maintenance costs.

Energy Storage Systems (ESS): For large-scale energy storage systems, such as those used in solar or wind power installations, cell balancing is critical for maintaining reliable power output and maximizing energy storage efficiency.

Robotics: In robotics, where reliability and performance are paramount, cell balancing ensures that the battery pack delivers consistent power, helping to prevent unexpected downtime or loss of power.

Power Tools and Consumer Electronics: Many cordless power tools and portable devices rely on balanced battery packs to ensure optimal performance and reliability over time.

Conclusion

Cell balancing is a key process in ensuring the safety, efficiency, and longevity of lithium-ion batteries. At HIMAX Electronics, we incorporate advanced cell balancing technologies into our Battery Management Systems (BMS), ensuring that your battery packs operate safely, efficiently, and reliably. Whether you are designing a high-performance electric vehicle, a solar energy storage system, or a robotics application, we provide tailored solutions to meet your specific energy storage needs.

By ensuring that all cells within a battery pack are balanced, we help extend the life of your batteries, improve their performance, and reduce the risks associated with imbalances. Contact HIMAX Electronics today to learn more about how our cell balancing solutions can help optimize your battery systems.