The Impact of Poor-Quality Batteries

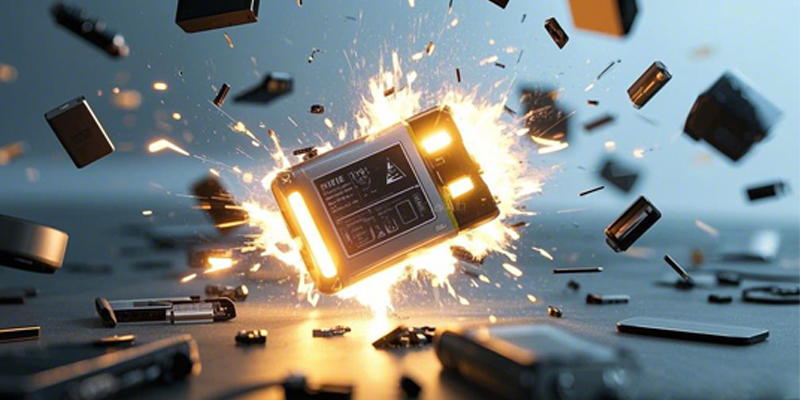

The consequences of sourcing poor-quality batteries can be catastrophic. Not only do these batteries often fail to meet performance expectations, but they can also pose serious risks to safety and reputation.

For sellers, a faulty battery could lead to costly product recalls. These recalls not only create financial burdens but also tarnish the company’s reputation. Your customers trust your product, and a failure in battery performance can result in the loss of that trust and, ultimately, customer loyalty.

For consumers, poor-quality batteries can cause malfunctioning products, damaging their devices and leading to frustration. When a battery doesn’t perform as promised—whether it runs out of charge too quickly, over-heats, or poses a fire risk—the resulting damage could be both costly and irreparable. Losing customer trust in this manner is a setback that can take years to overcome.

Key Certifications to Look For

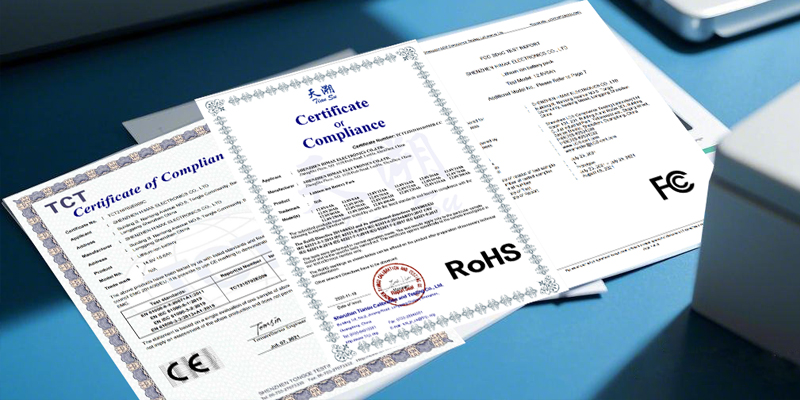

Understanding battery certifications is crucial to identifying the quality of a battery. Some key certifications include:

· UL Certification: UL (Underwriters Laboratories) is one of the most recognized safety standards. UL testing ensures that the battery has passed rigorous safety checks, particularly regarding issues like overheating, short-circuiting, or electrical faults that could lead to fire or injury.

· IEC 62133 Certification: This is a critical international safety standard for batteries used in portable devices. It specifies the requirements for the safety of lithium-based batteries, testing for various potential hazards such as leakage, mechanical integrity, and overcharge resistance.

· CE Certification: This indicates that the product complies with European Union safety, health, and environmental protection regulations. It’s often a requirement for battery manufacturers who want to sell their products in the European market.

· RoHS Compliance: The Restriction of Hazardous Substances (RoHS) directive ensures that the battery is free from harmful materials like lead, mercury, and cadmium, making it safer for both the environment and end users.

Having these certifications ensures that a battery has been thoroughly tested to meet rigorous safety standards, offering peace of mind for both manufacturers and consumers.

Finding a Reliable Battery Manufacturer

One of the biggest challenges in sourcing high-quality batteries is finding a manufacturer that is both trustworthy and consistent. As with any supplier, not all manufacturers operate with the same level of transparency, quality, or reliability.

To reduce the risk of sourcing poor-quality batteries, you need to partner with a manufacturer that not only provides the required certifications but also has a commitment to quality at every stage of production. A good manufacturer will offer transparency regarding their testing and certification processes and provide verifiable documentation and traceability for every batch of batteries they produce.

A trustworthy manufacturer will also provide clear and timely communication, especially when it comes to customized solutions. After all, the last thing you want is a battery that doesn’t fit the requirements of your product or, worse, a product that fails prematurely.

Himax’s Commitment to Quality

At Himax Batteries, we understand that quality is paramount when it comes to sourcing batteries. Here’s how we ensure that our products meet the highest standards:

· Comprehensive Quality Control: From cell selection to final product testing, we control every step of the manufacturing process. Our quality control team ensures that each battery meets both international and local safety standards before it leaves our factory.

· Custom Battery Solutions: We specialize in battery customization, ensuring that the battery matches your specific application and performance requirements. Whether you’re designing a solar battery system, a portable power bank, or an e-bike battery, our team will work closely with you to tailor the solution to your needs.

·Transparent Certification and Traceability: At Himax, we provide clear, verifiable certification documents for all our products. We also offer batch traceability, meaning you can access testing data for every order. This level of transparency ensures you can verify the authenticity of our certifications and the quality of our products before they reach your production line.

-

Warning: The Three “Low Price Traps”

While it might be tempting to source cheaper batteries, beware of the three low-price traps:

-

Uncertified Suppliers: Many low-priced battery suppliers cut costs by skipping crucial certification processes. Without certifications like UL or IEC, you’re at risk of receiving unsafe or unreliable products.

-

Hidden Quality Issues: Cheaper batteries may not have undergone rigorous testing, which can lead to hidden flaws, such as inconsistent performance or safety risks. These issues could become evident only after the batteries have been installed in your products and released to the market.

-

No Traceability: A supplier that doesn’t offer batch traceability is a major red flag. Without a clear record of where and how each battery was made, it becomes impossible to track defects, and you could be forced to recall products or deal with unhappy customers.

Remember, the old adage “you get what you pay for” holds true. While lower prices may seem appealing, they often come with hidden risks that could cost you far more in the long run.

Conclusion

In the competitive world of battery sourcing, quality certifications are not just an added benefit—they are essential for ensuring the safety, reliability, and performance of your products. By working with a reputable manufacturer like Himax, you can ensure that every battery you source is of the highest quality, with full transparency and compliance with international standards.

When it comes to sourcing batteries, don’t compromise on quality. Trust certified manufacturers who can guarantee their products meet rigorous safety and performance standards. It’s the best way to safeguard your brand’s reputation and your customers’ trust.