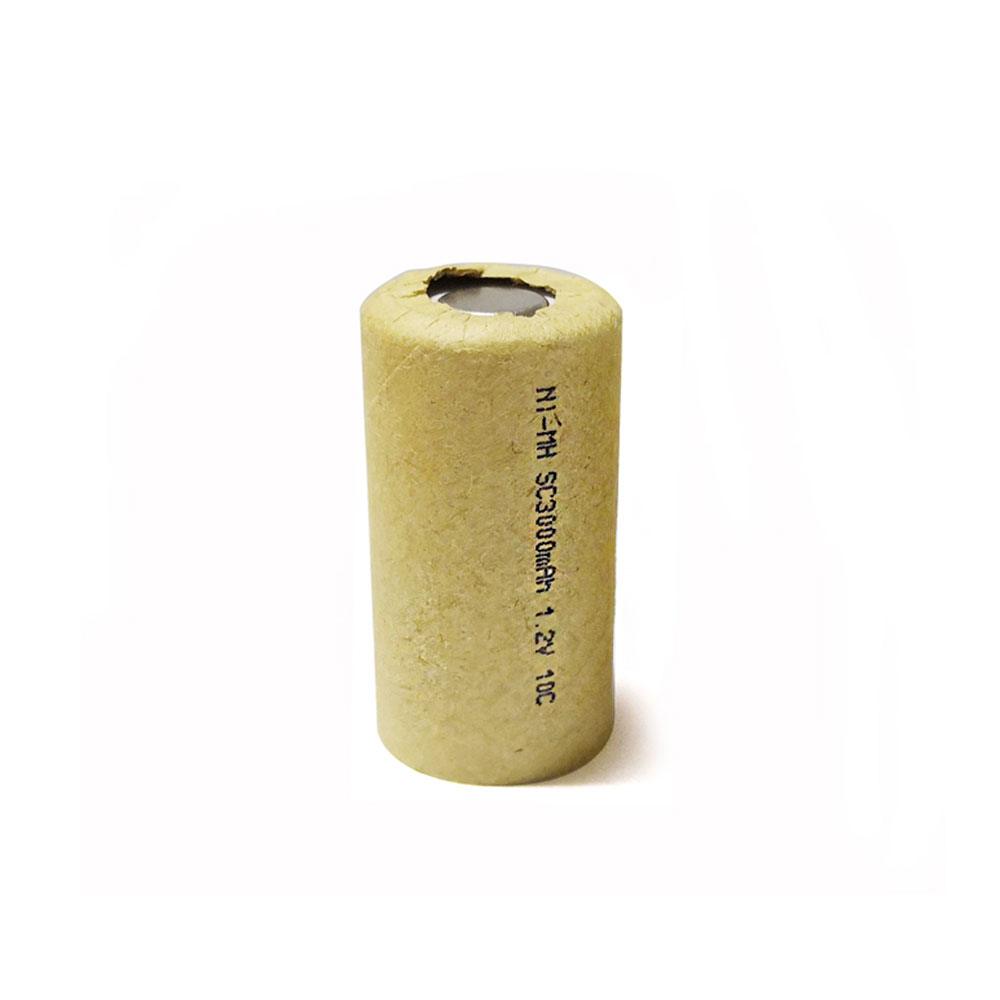

In the rapidly evolving world of security technology, reliable power solutions are critical for uninterrupted surveillance. Among the various battery options available, Nickel-Metal Hydride (Ni-MH) SC 1.2V 3000mAh batteries have emerged as a dependable choice for CCTV systems. Manufactured by Shenzhen Himax Electronics Co., Ltd, these Ni-MH battery offer high capacity, long cycle life, and environmental safety, making them ideal for security applications.

This article explores how Ni-MH batteries improve CCTV performance, why they are a sustainable alternative to traditional power sources, and their key advantages in security systems.

1. Why Ni-MH Battery is Ideal for CCTV Systems

High Capacity & Long Runtime

The high capacity ensures extended operation, reducing the frequency of battery replacements. This is crucial for 24/7 surveillance, where power interruptions can compromise security.

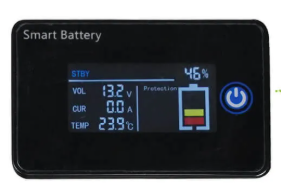

Stable Voltage Output

Unlike some rechargeable batteries that experience voltage drops, Ni-MH SC batteries maintain a steady 1.2V output, ensuring consistent performance for CCTV cameras and recording devices.

Wide Temperature Tolerance

CCTV systems often operate in varying climates. Himassi Ni-MH SC batteries perform reliably in both high and low temperatures, making them suitable for outdoor and indoor surveillance.

2. Why the Ni-MH Battery Beats Alternatives

Ni-MH Battery: An Eco-Friendly & Safe Choice

Compared to Ni-Cd (Nickel-Cadmium) batteries, Ni-MH batteries contain no toxic cadmium, making them environmentally friendly and compliant with global regulations.

Low Self-Discharge: Why Ni-MH Battery Holds Charge Longer

Many rechargeable batteries lose charge when idle. Himassi Ni-MH SC batteries feature a low self-discharge rate, retaining power for longer periods—essential for backup power in CCTV setups.

Ni-MH Battery Offers 500+ Cycles for Long-Term Savings

With up to 500+ charge cycles, these batteries offer long-term cost savings compared to disposable alkaline batteries, which need frequent replacement.

3. Applications in CCTV & Security Systems

Backup Power for Wireless Cameras

Wireless CCTV cameras rely on efficient battery power. The high capacity ensures prolonged operation during power outages.

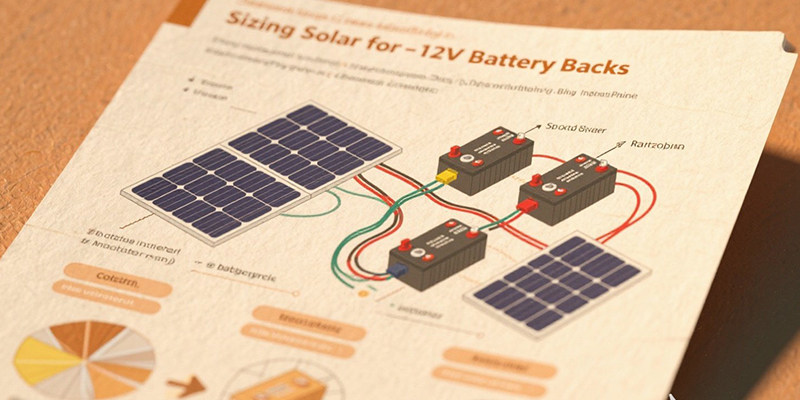

Solar-Powered Surveillance Systems

Ni-MH batteries pair well with solar-powered CCTV setups, storing energy efficiently for nighttime or low-light surveillance.

Emergency Power for DVR/NVR Systems

In case of mains failure, Ni-MH SC batteries can provide temporary power to Digital Video Recorders (DVRs) and Network Video Recorders (NVRs), preventing data loss.

4. Why Choose HiMASSi Ni-MH Batteries?

As a trusted manufacturer, Shenzhen Himax Electronics Co., Ltd ensures:

✔ High-quality materials for durability

✔ Strict quality control

✔ Competitive pricing without compromising performance

✔ Custom solutions for specialized security needs

Conclusion

The Ni-MH battery is a smart, sustainable, and cost-effective power solution for CCTV and security systems. With high capacity, stable performance, and eco-friendly benefits, it outperforms traditional battery options.

For security integrators and businesses seeking long-lasting, reliable power, HiMASSi Ni-MH batteries provide the ideal balance of performance and sustainability.