Picture this: you’re out in the vast wilderness, night falls, and your RV is aglow with warm lights, the fridge hums steadily, and a fan gently circulates cool air. What’s powering this cozy setup? A reliable lithium iron phosphate (LiFePO4) battery, quietly doing its job. Off-grid solar systems are captivating—not just for their eco-friendliness but for the freedom they offer, untethered from the grid! The 12.8V 100Ah LiFePO4 battery is like the “energy heart” of these systems, celebrated for its safety, long lifespan, and stellar performance. It’s the go-to choice for off-grid solar projects, whether you’re camping in an RV, powering solar streetlights in a remote village, or setting up emergency home energy storage. With its balanced capacity and voltage, this battery fits countless scenarios. This guide will walk you through how to select the perfect 12.8V 100Ah LiFePO4 battery for your off-grid solar project, making your energy journey smoother and more efficient!

The Appeal of Off-Grid Solar Systems and the Advantages of LiFePO4 Batteries

Why Are Off-Grid Solar Systems So Appealing?

An off-grid solar system is a standalone power setup, completely independent of the public grid. It harnesses sunlight, converts it into electricity, and stores it in a battery to keep your life powered up. Doesn’t that sound liberating? The core components include:

-

Solar Panels: Like sharp-eyed scouts, they capture every ray of sunlight and convert it into electricity.

-

Charge Controller: Think of it as the system’s “manager,” ensuring safe and orderly battery charging while preventing overcharging or over-discharging.

-

Battery: The “energy vault” that stores daytime power for use at night or on cloudy days.

-

Inverter: A “translator” that converts DC power into AC to run your household appliances.

-

Loads: From lights to fridges to TVs, these are the everyday devices that rely on your system.

The battery is the heart of this setup. Its performance determines whether the system runs reliably and lasts long. The 12.8V 100Ah LiFePO4 battery, with its high energy density and dependability, is a top pick for many off-grid projects.

Why Are LiFePO4 Batteries So Impressive?

Compared to traditional lead-acid batteries, LiFePO4 batteries are like a dark horse, standing out with these key advantages:

-

Rock-Solid Safety: Their stable chemistry means virtually no risk of thermal runaway or explosions—peace of mind, even in rugged outdoor settings.

-

Longevity Like an Evergreen: They handle over 2,000 charge-discharge cycles, dwarfing lead-acid’s 500 cycles, earning them the “longevity champ” title.

-

Light as a Feather: For the same capacity, they’re smaller and lighter, making installation and transport a breeze.

-

Adaptable Like a Mustang: They perform reliably from -20°C (-4°F) freezing cold to 60°C (140°F) scorching heat, thriving in diverse climates.

-

Low Self-Discharge: Minimal power loss during long-term storage makes them a “loyal guardian” for off-grid systems.

Aren’t these features enough to make you trust LiFePO4 batteries? They’re the perfect partner for off-grid solar projects!

How to Accurately Select a 12.8V 100Ah LiFePO4 Battery

Choosing a battery isn’t just about picking one off the shelf—it’s like building with Lego blocks. You need to consider your power needs, solar panel output, charge controller compatibility, and installation environment. Here’s a step-by-step guide to make it easy!

Step 1: Calculate Your Power Needs—Know Your Numbers

The first step is figuring out how much power you need. A 12.8V 100Ah LiFePO4 battery has a theoretical capacity of 12.8V × 100Ah = 1,280Wh (watt-hours), meaning it stores 1,280 watt-hours of energy. Let’s say your setup includes:

-

4 LED Lights (10W each), running 8 hours nightly: 10W × 4 × 8h = 320Wh.

-

A 50W Mini Fridge, running 12 hours daily: 50W × 12h = 600Wh.

-

A 20W Fan, running 6 hours: 20W × 6h = 120Wh.

Total power consumption: 320Wh + 600Wh + 120Wh = 1,040Wh. Looks perfect, right? But here’s a key detail: to extend battery life, keep the depth of discharge (DoD) at 80%, meaning the usable capacity is 1,280Wh × 80% = 1,024Wh. Your 1,040Wh need slightly exceeds 1,024Wh, which could strain a single battery. What’s the fix? Connect two 100Ah batteries in parallel to double the capacity to 200Ah, or reduce your load slightly. Problem solved!

Step 2: Match Your Solar Panels—Maximize Sunlight

Solar panels are the system’s “power source,” and their output and voltage must align with the battery. A 12.8V LiFePO4 battery typically charges at 14.4V–14.6V, so your solar panel’s open-circuit voltage should be 18V–20V for efficient charging.

How do you calculate the required power? If your area gets 5 hours of effective sunlight daily and the battery needs to charge fully (1,280Wh), accounting for system efficiency (about 85%), the required solar panel power is: 1,280Wh ÷ (5h × 0.85) ≈ 300W. A 300W–400W solar panel is ideal. If you choose a 400W panel (designed for 24V), you can configure it with series or parallel connections. Doesn’t that flexibility feel empowering?

Step 3: Choose a Charge Controller—Efficiency Meets Safety

The charge controller is the “bridge” between your solar panels and battery, and it must support LiFePO4 battery charging. An MPPT (Maximum Power Point Tracking) controller is like an “efficient manager,” outperforming PWM controllers by 15%–20%, especially in cloudy or inconsistent light conditions.

What parameters matter? Focus on:

-

Voltage: Must support the 12.8V battery’s charging voltage (14.4V–14.6V).

-

Current: A 400W solar panel outputs roughly 400W ÷ 18V ≈ 22A. A 30A MPPT controller provides extra headroom for stable operation.

Step 4: Parallel or Series Connections—Scale with Ease

Need more power? Parallel or series connections make it simple:

-

Parallel: Two 100Ah batteries in parallel boost capacity to 200Ah while keeping voltage at 12.8V—great for small system expansions.

-

Series: Four batteries in series raise the voltage to 51.2V while keeping capacity at 100Ah, ideal for 48V systems.

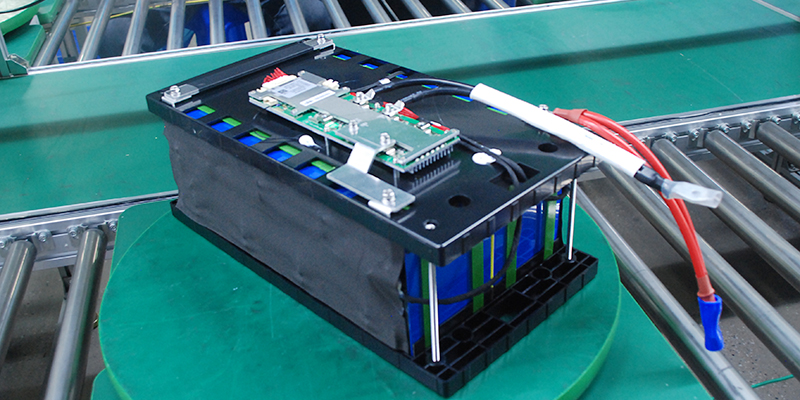

A key note: when connecting batteries, ensure they’re the same brand and model, and use a BMS (Battery Management System) for safety. Doesn’t this flexibility make scaling feel effortless?

Step 5: Consider the Installation Environment—Details Matter

Off-grid systems often live outdoors, so environmental factors are critical:

-

Waterproofing: Does the battery have a waterproof casing? If not, install it in a waterproof enclosure to protect against rain and moisture.

-

Temperature: LiFePO4 batteries are adaptable, but extreme heat or cold should be avoided to maintain performance.

-

Ventilation: While highly safe, good airflow helps with heat dissipation and extends battery life.

These details remind you to stay thorough when planning, don’t they?

Common Questions Answered—Clearing Up Your Doubts

Why Choose a 12.8V 100Ah LiFePO4 Battery?

This battery, made of four 3.2V cells in series, delivers a voltage that matches most 12V loads. Its 100Ah capacity strikes a perfect balance for small to medium off-grid systems, whether for RV camping, solar streetlights, or home energy storage. With top-notch safety and longevity, isn’t its value hard to beat?

How to Make Your Battery Last Longer?

-

Avoid Over-Discharging: Keep the depth of discharge below 80% for a longer lifespan.

-

Regular Maintenance: Check connections and BMS status to ensure everything’s running smoothly.

-

Store at Proper Temperatures: Avoid extreme heat or cold to keep the battery healthy.

-

Use a Dedicated Charger: Match the charger to LiFePO4 specifications to prevent damage.

These tips boost your confidence in battery care, don’t they?

LiFePO4 vs. Lead-Acid—Which Wins?

LiFePO4 batteries are like “light cavalry”—lightweight, long-lasting, and efficient, making them a smart long-term investment. Lead-acid batteries, while cheaper, are like “seasoned veterans”—heavier, shorter-lived, and costlier to maintain. Which would you pick?

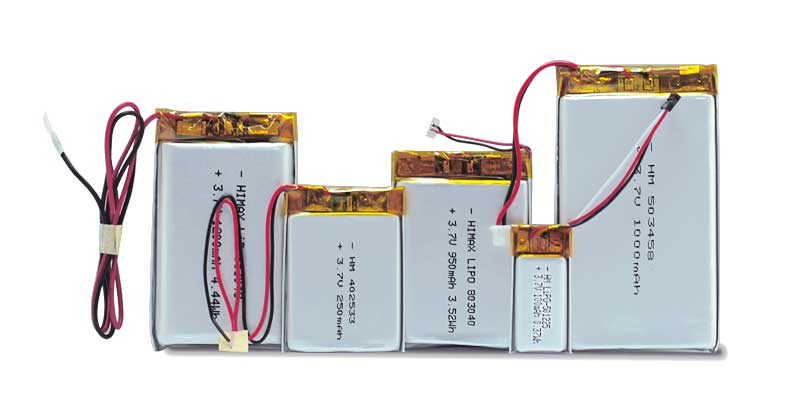

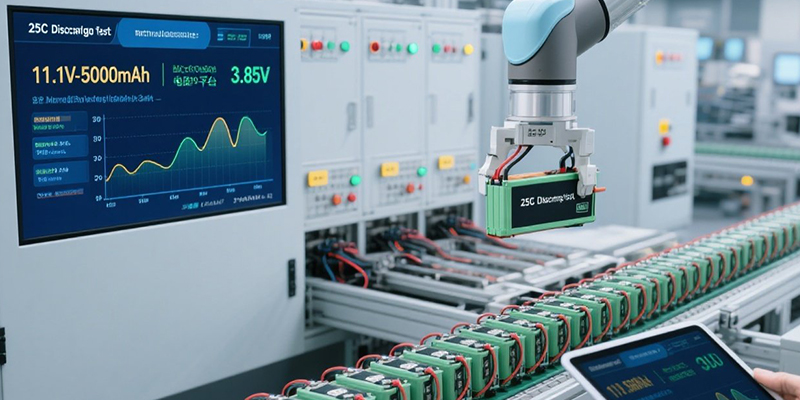

HIMAX LiFePO4 Batteries—Your Trusted Partner

HIMAXis dedicated to delivering high-quality energy solutions worldwide. Our 12.8V 100Ah LiFePO4 battery uses top-grade cells and a built-in smart BMS, offering protection against overcharging, over-discharging, overcurrent, and short circuits—reliable as a rock! With fast charging and discharging and a lifespan exceeding 2,000 cycles, it’s perfect for off-grid solar systems, RV camping, home energy storage, and more.

HIMAX Tips 1: How to Choose the Right 12V Battery Pack Size for Solar Panels

HIMAX Tips 2: How to Design the Perfect Custom Battery for Your Solar System