-

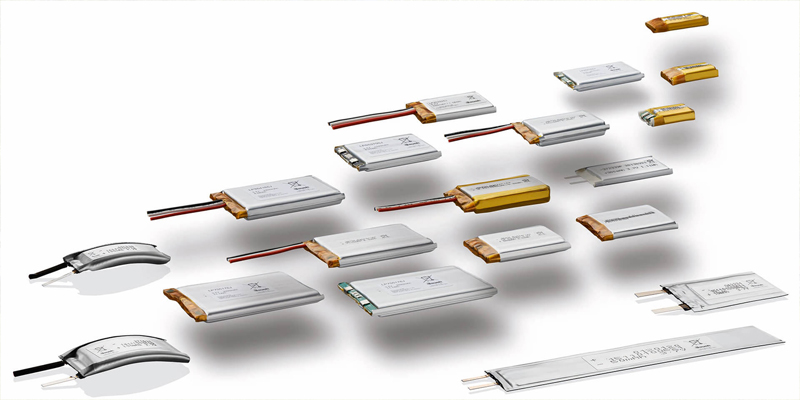

Introduction: What is a Custom LiPo Battery?

Lithium Polymer (LiPo) batteries are a popular choice for a variety of applications due to their lightweight, high energy density, and flexibility in design. These batteries are made using a polymer electrolyte instead of a liquid electrolyte, which provides advantages such as lighter weight and more flexibility in battery shapes. LiPo batteries are commonly used in devices like drones, remote-controlled vehicles, portable electronics, and even electric vehicles.

However, not all devices require the same type of battery. Each application may have unique power, size, or voltage requirements, which is where

custom LiPo batteries come into play. Custom LiPo batteries are designed to meet the specific needs of a project or device, ensuring optimal performance and longevity.

In this guide, we will explore how you can select the right custom LiPo battery solution for your project, including the differences between 2S, 3S, 4S, and 6S batteries, and why a tailored battery solution is essential for achieving the best results.

-

Why Choose Custom LiPo Battery Solutions?

When choosing a LiPo battery for your project, a custom battery solution provides several key advantages over off-the-shelf batteries. Here’s why:

2.1. Improved Performance and Longevity

Custom LiPo batteries can be optimized to deliver the exact voltage and capacity your device needs. Unlike standard batteries, which may either provide too much or too little power, a custom battery ensures that your device operates at peak performance. In addition, by tailoring the battery to your specific needs, you can improve its overall lifespan and reduce the risk of premature failure.

2.2. Better Compatibility

Devices have unique power requirements based on factors such as voltage, current, and capacity. Customizing a battery ensures compatibility with your device’s power system, preventing potential damage from using an incompatible battery. For example, drones that require higher discharge rates will benefit from a custom battery designed for such needs.

2.3. Meeting Specific Needs

Different industries and applications require batteries with specific properties. For example:

-

Drones: A drone used for high-resolution aerial photography may need a battery with higher energy density to extend flight times.

-

Electric Vehicles: Vehicles such as e-bikes or electric cars need batteries that offer high power output for longer ranges and faster charging times.

-

Robotics: Robots used for industrial tasks often need batteries that provide high power output and are lightweight enough for efficient mobility.

2.4. Ensuring Safety, Stability, and Efficiency

Custom batteries are designed and tested to meet rigorous safety standards. This includes checking for potential hazards such as overheating or battery leakage. Custom batteries are also optimized for efficient energy use, ensuring your device runs smoothly without draining too quickly or overloading the system.

-

Differences and Applications of 2S, 3S, 4S, and 6S LiPo Batteries

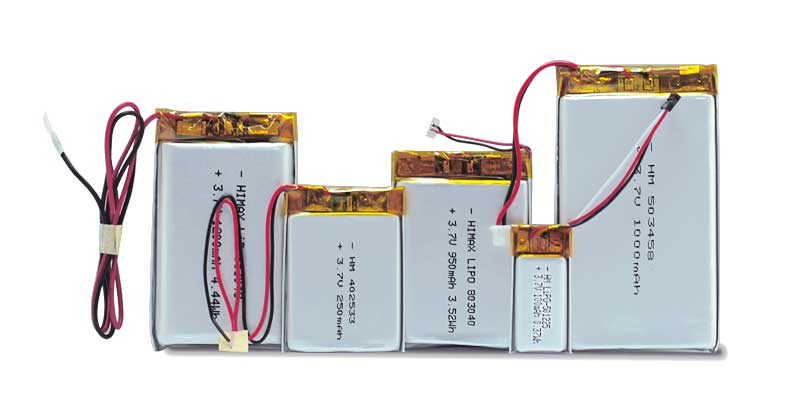

When selecting a custom LiPo battery, it’s important to understand the difference between the various configurations, such as 2S, 3S, 4S, and 6S. These configurations refer to the number of cells connected in series, which directly affects the voltage and capacity of the battery.

3.1. 2S Battery

-

Voltage: A 2S battery consists of two cells connected in series, providing a nominal voltage of 7.4V (3.7V per cell).

-

Common Uses: This configuration is ideal for low-power applications like mini drones, small robots, and electronic devices. It provides enough power for smaller devices without being too heavy.

-

Performance: Suitable for devices that don’t require extended flight times or high power demands.

3.2. 3S Battery

-

Voltage: A 3S battery consists of three cells, providing a nominal voltage of 11.1V (3.7V per cell).

-

Common Uses: Frequently used in medium-sized drones, remote-controlled cars, and other hobbyist applications.

-

Performance: Offers a higher power output than a 2S battery, making it suitable for devices that require more energy for moderate tasks, such as aerial photography drones.

3.3. 4S Battery

-

Voltage: A 4S battery consists of four cells, providing a nominal voltage of 14.8V (3.7V per cell).

-

Common Uses: This configuration is often used for high-performance drones, remote-controlled vehicles, and models that demand higher power outputs.

-

Performance: Provides better efficiency and longer operational time for devices that need more power, such as FPV drones or heavy-duty robotics.

3.4. 6S Battery

-

Voltage: A 6S battery has six cells, offering a nominal voltage of 22.2V (3.7V per cell).

-

Common Uses: This configuration is often used for professional drones, race drones, or heavy industrial applications where high power is required for demanding tasks.

-

Performance: It delivers a significant power boost, making it ideal for devices that need high discharge rates or extended runtimes.

3.5. Key Differences in Performance, Flight Time, Weight, and Cost

-

Voltage and Power: As the number of cells increases, so does the battery voltage, which directly translates to increased power output and performance.

-

Flight Time and Capacity: Batteries with more cells generally provide longer flight or operational times. However, this also means they are larger and heavier.

-

Weight: Higher cell-count batteries like 4S and 6S are heavier, which may affect the weight distribution and efficiency of smaller devices like drones.

-

Cost: More cells typically lead to higher costs, but they also offer more power and efficiency for demanding applications.

-

How to Choose the Right LiPo Battery Configuration?

Choosing the correct 2S, 3S, 4S, or 6S LiPo battery depends on your specific needs and the application of your device. Here are some considerations for making the best choice:

4.1. Device Type

-

Small Devices: If you are working with small devices like RC cars, mini drones, or handheld electronics, a 2S battery is often sufficient.

-

Medium Devices: For medium-sized drones or devices that need moderate power, a 3S or 4S battery will offer the right balance of performance and weight.

-

High-Power Devices: If you are building a high-performance drone, race drones, or industrial equipment, a 6S battery is ideal for providing the necessary power for demanding tasks.

4.2. Power and Flight Time Requirements

-

Power: Higher cell-count batteries provide more power, which is essential for high-speed tasks, heavy lifting, or extended operations.

-

Flight Time: If long flight times or extended operation is crucial, consider a higher cell-count battery for better performance.

4.3. Weight Considerations

If your project involves weight-sensitive devices, such as smaller drones, the weight of the battery should be carefully considered. A 2S or 3S battery might be a better choice for lightweight devices.

-

HIMAX Electronics Custom LiPo Battery Advantages

At HIMAX Electronics, we pride ourselves on offering high-quality, custom LiPo batteries tailored to your unique project needs. Here are some reasons why HIMAX should be your go-to source for custom batteries:

5.1. Expertise and Experience

With years of experience in battery technology, HIMAX specializes in creating custom battery solutions that meet the specific demands of various industries, including drones, robotics, and electric vehicles.

5.2. High-Quality and Reliable Solutions

We prioritize quality in every custom battery we design, ensuring that each battery meets the highest standards of performance, safety, and reliability.

5.3. Tailored to Your Needs

Whether you need a 2S, 3S, 4S, or 6S battery, HIMAX can customize the battery’s voltage, capacity, and size to suit your exact requirements.

5.4. Performance and Safety Assurance

Our LiPo batteries undergo extensive testing to ensure they perform at their best and meet rigorous safety standards.

-

Common FAQs About Custom LiPo Batteries

6.1. How long does it take to customize a battery?

The time to customize a battery depends on the complexity of the project, but most customizations can be completed within a few weeks.

6.2. How do I ensure the safety of my custom battery?

We conduct thorough testing to ensure each battery complies with safety standards and is free from hazards like overheating or leakage.

6.3. Can custom batteries support fast charging?

Yes, we can design custom batteries that support fast charging to suit your needs.

6.4. Do you provide warranty and after-sales support?

Yes, HIMAX offers warranties and after-sales services to ensure the continued performance of your custom battery.

-

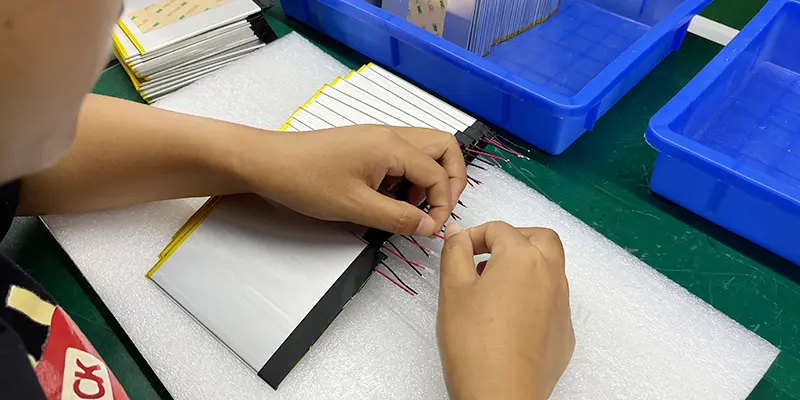

HIMAX Electronics Custom Battery Service Process

At

HIMAX Electronics, we follow a streamlined process to provide you with the perfect custom battery. Here’s how it works:

-

Step 1: Understanding your needs. We discuss the device, power requirements, and other parameters to design the perfect battery.

-

Step 2: Customization—Based on your specifications, we design and build your battery.

-

Step 3: Testing and Quality Assurance—Once the custom battery is built, it undergoes rigorous testing to ensure that it meets all performance, safety, and efficiency standards.

-

Step 4: Delivery—After the testing phase, we ensure your custom battery is delivered within the agreed timeframe and fully prepared for integration into your project.

Our custom battery design process is flexible and highly focused on meeting your specific needs, from the initial consultation to final delivery. We work closely with you to ensure that the solution provided aligns perfectly with your project’s requirements.

-

Conclusion: Why Choose HIMAX Electronics for Your Custom LiPo Battery Needs

In conclusion, custom LiPo batteries are a powerful and essential solution for projects that require specific power, size, and performance attributes. Whether you’re working with drones, robotics, electric vehicles, or any other application, selecting the right battery configuration can make all the difference in achieving optimal performance.

HIMAX Electronics has the expertise, experience, and commitment to quality that you need when it comes to designing and manufacturing custom LiPo battery solutions. We provide high-performance, safe, and reliable batteries that are tailor-made to fit your needs. With our comprehensive design, testing, and delivery process, you can rest assured that your custom battery solution will meet the highest standards.

If you’re ready to take your project to the next level with a custom 2S, 3S, 4S, or 6S LiPo battery, don’t hesitate to reach out to HIMAX Electronics. Our team is ready to help you craft the perfect battery solution for your application.