In today’s fast-paced world, convenience and mobility are no longer luxuries—they are expectations. One device that has grown increasingly popular in recent years is the heated lunch box, allowing users to enjoy warm meals anytime and anywhere. From office workers and students to delivery drivers and field engineers, the demand for portable, reliable food-heating solutions continues to rise. Among the various power options available, lithium batteries have emerged as the top choice for this application. At Himax Electronics Co., Ltd., we specialize in providing reliable lithium battery packs tailored to heated lunch box manufacturers worldwide. But why are lithium batteries such a smart fit for this niche product? Let’s explore the reasons in detail.

1. Compact Size and Lightweight Advantage

One of the key selling points of a heated lunch box is its portability. Users expect the device to be easy to carry, especially when used in commuting or outdoor environments. This is where lithium batteries shine.

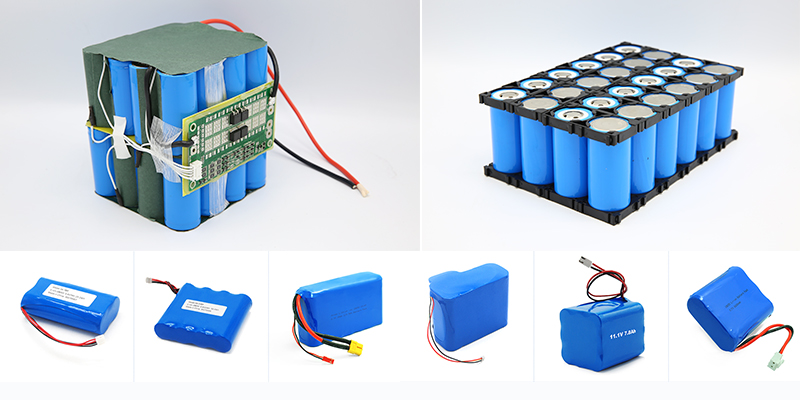

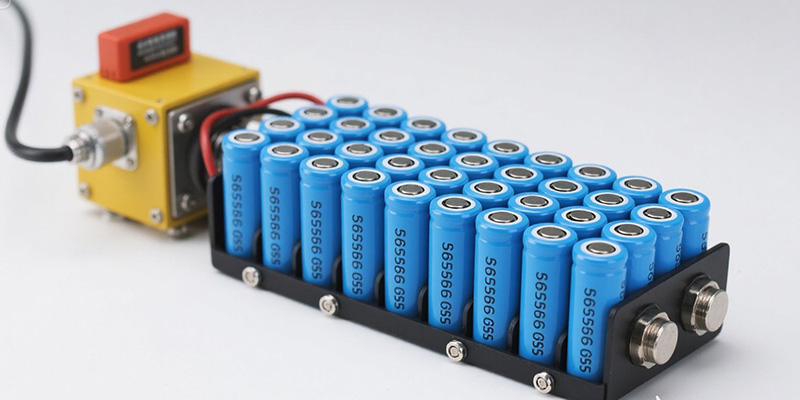

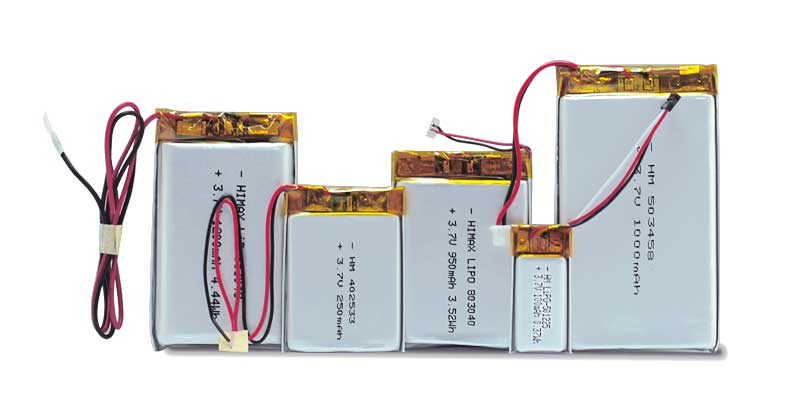

Lithium-ion and lithium-polymer (LiPo) batteries offer superior energy density compared to traditional battery types like nickel-metal hydride (NiMH) or sealed lead-acid (SLA) batteries. This means more power can be stored in a smaller and lighter package, directly benefiting the design of lunch boxes. Manufacturers can reduce the size and weight of the unit without sacrificing performance.

At Himax, we’ve developed custom lithium battery packs such as 3.7V 5000mAh or 7.4V 4000mAh configurations that are slim and compact enough to fit into small compartments, all while powering a heating element for up to an hour or more.

2. Higher Efficiency and Stable Output

A heated lunch box needs to deliver consistent heating performance, typically using a low-voltage heating plate or ceramic heating element. To do this effectively, the battery must deliver a stable output over the entire discharge cycle.

Lithium batteries are known for their flat discharge curve, which means they can maintain a consistent voltage output until the charge is nearly depleted. This contrasts with NiMH batteries, whose voltage drops more rapidly during use. This consistent power delivery is essential to keep food heated evenly, avoiding cold spots or underperformance.

Moreover, lithium batteries are highly efficient, reducing energy loss during discharge. For users, this translates into faster heating times and longer operating durations, even in compact designs.

3. Fast Charging Capabilities

Nobody wants to wait hours for their lunch box battery to recharge. One of the greatest benefits of lithium battery technology is its fast charging capability.

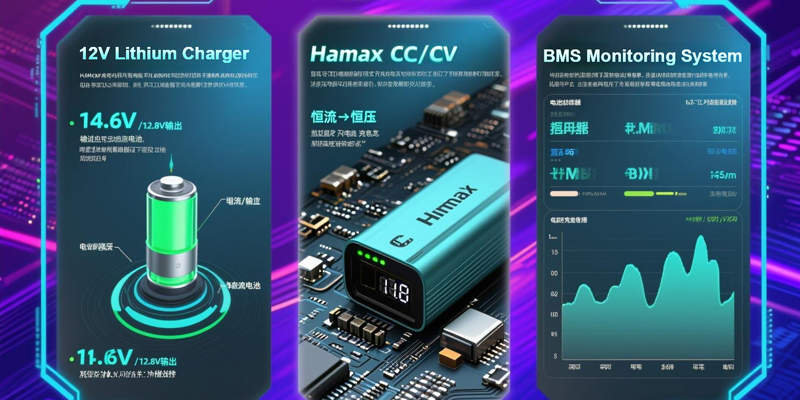

Lithium batteries typically support 1C charging rates, and with smart Battery Management Systems (BMS), can be safely recharged in 1 to 2 hours depending on capacity. Some advanced models even support USB-C charging, allowing users to top up the battery using power banks, car chargers, or wall adapters.

At Himax, we offer custom charging solutions, integrating protection circuits and smart charging modules that ensure both safety and speed, giving users peace of mind.

4. Longer Lifespan for Daily Use

Heated lunch boxes are often used daily, so battery durability becomes a major consideration. Fortunately, lithium batteries are built for longevity.

Whereas NiMH or SLA batteries may last for a few hundred cycles, LiFePO4 and Li-ion batteries can exceed 800–1000 charge/discharge cycles with proper care. This means the battery will continue to perform well even after a year or two of daily use.

Longer battery life also contributes to lower maintenance costs and a better user experience over time, reducing the need for frequent replacements.

Himax’s lithium battery packs are rigorously tested to meet international safety and durability standards (such as UN38.3, MSDS, CE, and RoHS), ensuring that manufacturers can confidently deliver a product that lasts.

5. Enhanced Safety Features

Safety is critical, especially when combining electricity with food and heat. Lithium battery packs designed for lunch boxes must be robust against overcharging, overheating, and short-circuit risks.

Modern lithium batteries come with built-in Battery Management Systems (BMS), which offer multiple levels of protection:

Overcharge/over-discharge protection

Short circuit protection

Temperature control

Balance charging (in multi-cell configurations)

At Himax, we customize our lithium battery packs with advanced BMS modules tailored to the application, ensuring safe performance in a wide range of environments—including offices, schools, and outdoors.

6. Eco-Friendly and Compliant with Regulations

Consumers are becoming more environmentally conscious, and product regulations are getting stricter worldwide. Compared to older battery chemistries, lithium batteries are more eco-friendly, especially LiFePO4, which contains no toxic heavy metals.

They are easier to recycle, and thanks to their longer lifespan, generate less electronic waste over time. Most importantly, lithium batteries meet the requirements of RoHS, REACH, and UN38.3 transport regulations—essential for global export.

Himax helps manufacturers meet these requirements by providing complete certification documentation, simplifying the compliance process.

Conclusion: Himax Powers a Smarter Lunch Experience

Heated lunch boxes are not just a gadget—they represent a shift toward healthier, more convenient lifestyles. And powering them efficiently and safely is at the core of delivering user satisfaction.

Lithium batteries offer a perfect blend of power, size, reliability, and safety, making them the ideal energy source for this application. Whether it’s rapid heating, compact form factors, or long battery life, lithium technology checks all the boxes.

At Himax Electronics Co., Ltd., we bring over 13 years of experience in customizing Lithium and NiMH battery packs for global B2B clients. Our batteries power not only lunch boxes but also Bluetooth devices, medical tools, and portable lighting systems.

If you’re a manufacturer of heated lunch boxes looking for a reliable battery partner, contact Himax today—we’re ready to help you bring innovation and power into the hands of your customers.