Introduction

Lithium Iron Phosphate (LiFePO4) batteries have gained popularity for their high energy density and long cycle life. To ensure the safety and optimal performance of 12V 400Ah LiFePO4 batteries, it is crucial to follow proper charging methods and guidelines. By adhering to recommended practices, users can prevent common issues such as undercharging or overcharging, both of which can significantly impact battery life and functionality.

Basic Principles of LiFePO4 Battery Charging

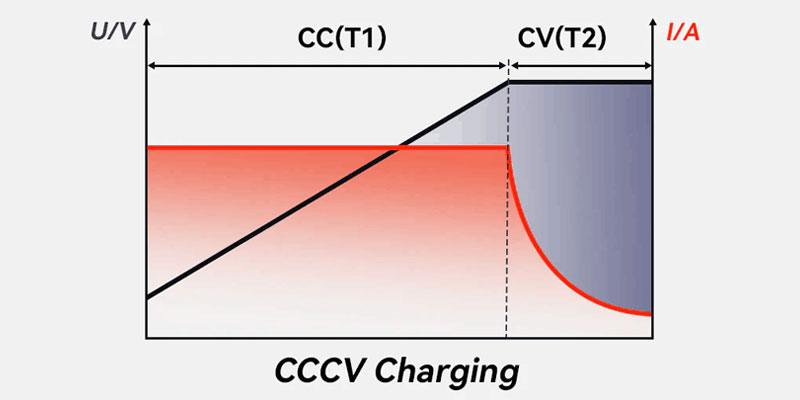

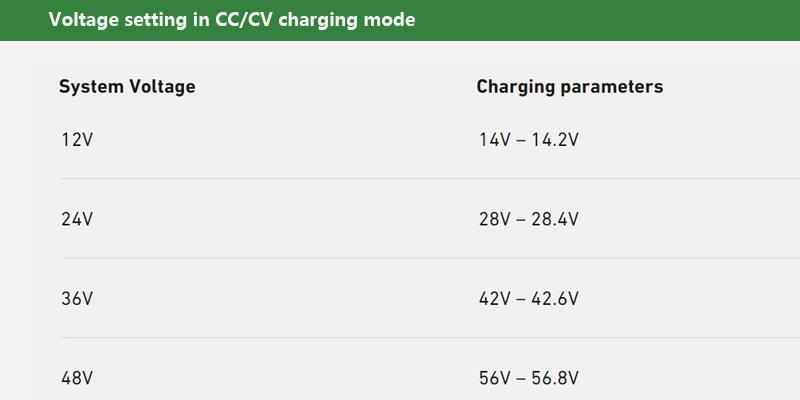

The lithium iron phosphate battery pack charging mode adopts CC/CV.

LiFePO4 battery chargers can behave in several different ways during the charging process. First, the charger can steadily increase its voltage to keep the current constant. This is the first stage of the charging process – often referred to as the “bulk” charging phase. During this phase, the charger adjusts its applied voltage to provide maximum current to the battery.

For example, a 12V 400Ah LiFePO4 battery using an 80 amp charger will deliver a maximum current of 80 amps during this batch charging stage and the applied voltage will increase to the maximum voltage or “batch voltage”.

The maximum charging voltage for a 12V LiFePO4 battery is 14.6 V. When the LiFePO4 battery 12V 400Ah reaches 14.6 V, the battery is fully charged.

Once the maximum voltage is reached, the charger enters a second phase called the “Absorption”charging phase. During the absorption period, the charger applies a constant voltage, called the “absorption voltage”. When the open circuit voltage of the battery approaches the absorption voltage, the current will gradually decrease to zero.

At this point, the battery is fully charged. LiFePO4 batteries do not require float charging because they do not lose a significant amount of charge when disconnected from the charger and have a low self-discharge in the absence of a load.

Recommended Charging Parameters for 12V 400Ah LiFePO4 Battery

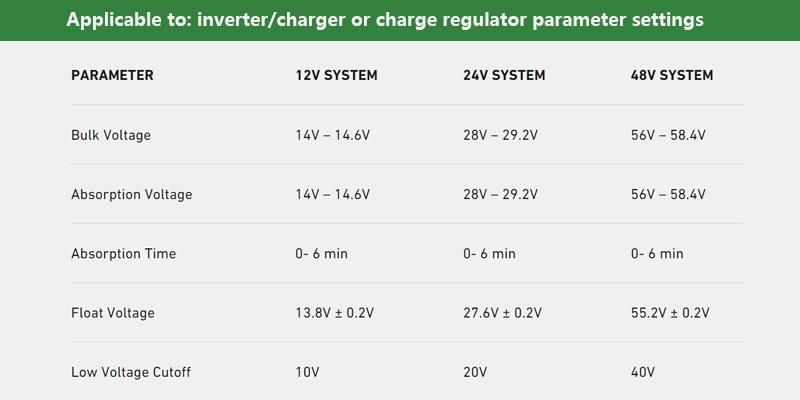

Properly setting the charging parameters for a 12V 400Ah LiFePO4 battery is crucial to optimize battery life and performance. Here’s a detailed breakdown of the settings for both the bulk and absorption charging phases:

Bulk Charging Phase:

- Purpose: The bulk phase is intended to quickly bring the battery up to approximately 70-80% of its full charge capacity. This is achieved by delivering a consistent, high current to the battery.

- Voltage Setting: The target voltage for bulk charging should typically be set at 14.6V. This voltage is optimal for LiFePO4 batteries as it maximizes charging efficiency without straining the battery’s internal chemistry.

- Current Setting: It is recommended to set the charging current at no more than 0.2C during the bulk phase. For a 400Ah battery, this translates to 80A. This rate ensures that the battery is charged quickly but safely, preventing excessive heat buildup which can degrade battery life.

Absorption Charging Phase:

- Purpose: The absorption phase completes the charging process by slowly topping off the battery. This phase is crucial for achieving a full charge and for balancing the cells within the battery, which enhances both performance and longevity.

- Voltage Setting: The voltage should remain at 14.6V, the same as in the bulk phase. Maintaining this constant voltage ensures that the battery reaches its full potential without the risk of overvoltage.

- Current Setting: During absorption, the current naturally tapers off as the battery approaches full capacity. The charging system should allow the current to decrease until it reaches about 3-5% of the battery’s capacity (12A to 20A for a 400Ah battery). This gradual reduction in current helps to prevent overcharging and ensures thorough, even charging of all cells.

Duration:

- The duration of the absorption phase can vary but typically lasts until the charging current drops to a low threshold, indicating that the battery is fully charged. For a 400Ah battery, this phase might last several hours, depending on the initial state of discharge and the efficiency of the charging equipment.

These settings are guidelines that can be adjusted based on specific usage conditions and the advice of the battery manufacturer. Regular monitoring and adjustments based on performance data can help in fine-tuning these parameters to better suit individual needs.

Choosing and Setting Up the Charger

Selecting the right charger and properly configuring it are critical steps to ensure that your 12V 400Ah LiFePO4 battery charges efficiently and safely. Here’s what you need to consider:

Choosing the Right Charger:

- Compatibility: Ensure the charger is compatible with LiFePO4 batteries. Not all chargers are created equal, and using one that’s designed for a different type of battery can lead to inefficient charging or even damage.

- Adjustable Settings: Opt for a charger that allows you to adjust voltage and current settings. This flexibility is crucial for setting precise charging parameters that match the needs of your specific battery model.

- Quality and Reliability: Choose a charger from a reputable manufacturer that adheres to safety standards. A high-quality charger might cost more initially but will provide reliable performance and prevent issues related to overcharging or undercharging.

Setting Up the Charger:

- Voltage and Current Settings: Based on the recommended parameters, set the charger to deliver a bulk charge of 14.6V and limit the current to 80A. For the absorption phase, maintain the voltage at 14.6V while allowing the current to taper off as the battery approaches full charge.

- Monitoring Tools: If possible, use a charger with built-in monitoring capabilities. These can provide real-time feedback on voltage, current, and charge progression, which helps in adjusting settings if necessary and prevents charging issues.

- Safety Features: Ensure the charger has necessary safety features such as overvoltage protection, short circuit protection, and thermal shutdown. These features help protect both the battery and the charger from potential damage during the charging process.

Properly setting up your charger not only optimizes the charging process but also extends the life of your battery. Taking the time to configure these settings correctly can make a significant difference in the performance and longevity of your 12V 400Ah LiFePO4 battery.