Australia has seen a remarkable increase in renewable energy adoption in recent years, driven by favorable government policies, advancements in solar technology, and growing environmental awareness. The need for effective energy storage solutions has become paramount for both households and businesses seeking to maximize the use of renewable energy and reduce dependence on the grid. Choosing the right battery storage solution can make all the difference in terms of energy efficiency, cost savings, and reliability.

In this guide, we provide Australian buyers with an overview of the latest battery storage trends and offer practical advice on choosing the best storage solution for their needs. Whether you are a homeowner looking to store excess solar power or a business aiming to manage energy costs, understanding these battery trends will help you make an informed decision.

Energy Storage Demand in the Australian Market

Australia’s energy landscape is rapidly evolving, with renewable energy playing an increasingly significant role in the country’s electricity supply. Government initiatives, such as the Renewable Energy Target (RET) and various state-based incentives, have encouraged the adoption of solar energy and energy storage systems. Homeowners and businesses alike are increasingly turning to solar energy combined with battery storage to harness the power of the sun and reduce electricity bills.

For many Australian households, storing excess solar energy is key to maximizing self-sufficiency. By using battery storage systems, excess energy generated during the day can be stored and used during the evening or on cloudy days when solar generation is low. Additionally, businesses are adopting energy storage solutions to manage energy costs and reduce their reliance on the grid, especially during peak hours when electricity rates are higher.

In rural and remote areas of Australia, energy storage plays a vital role in ensuring access to reliable power. Many of these areas are not connected to the main power grid, making battery storage systems an essential solution for achieving energy independence and maintaining uninterrupted power supply.

Current Battery Technology Trends

The energy storage market offers a range of battery technologies, each with its own set of advantages and disadvantages. Here are the main types of batteries currently available for energy storage in Australia:

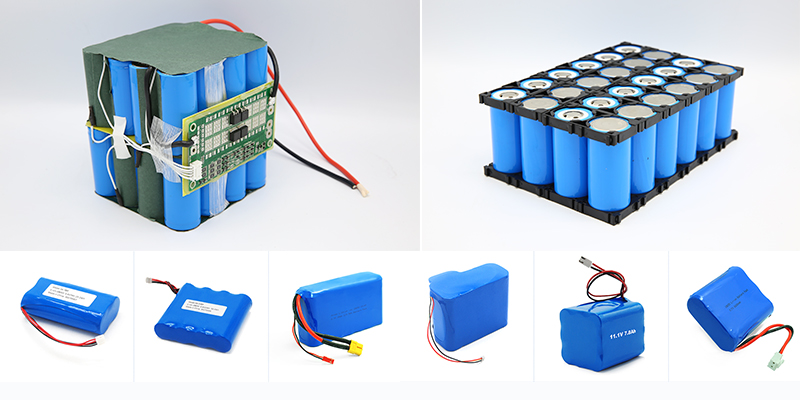

– **Lithium-Ion Batteries**: Lithium-ion batteries are the most widely used type of battery for energy storage, both for residential and commercial purposes. They are known for their high energy density, which means they can store a large amount of energy in a compact size. Lithium-ion batteries are also lightweight, have a long cycle life, and are relatively efficient, making them a popular choice for solar energy storage.

– **Solid-State Batteries**: Solid-state batteries are an emerging technology that offers several advantages over traditional lithium-ion batteries, including increased safety and energy density. Unlike lithium-ion batteries, which use a liquid electrolyte, solid-state batteries use a solid electrolyte, reducing the risk of leaks and fire. Although they are still in the early stages of commercialization, solid-state batteries hold great promise for the future of energy storage.

– **Lithium Iron Phosphate (LFP) Batteries**: LFP batteries are a type of lithium-ion battery that is known for its enhanced safety and thermal stability. While they have a lower energy density compared to other lithium-ion chemistries, LFP batteries are extremely durable, making them well-suited for applications where longevity and safety are more important than maximizing energy density. They are increasingly being used in residential and commercial energy storage systems.

In addition to these established technologies, there are several new and emerging battery technologies that are being explored for future use in energy storage. These include sodium-ion batteries and flow batteries, both of which offer unique advantages and could play a role in the future of energy storage in Australia.

Key Considerations for Choosing the Right Battery Storage Solution

Choosing the right energy storage solution involves considering several factors to ensure that it meets your needs and expectations. Here are some of the key considerations to keep in mind when selecting a battery storage solution:

– **Energy Density and Battery Life**: Energy density refers to the amount of energy that a battery can store per unit of volume. A higher energy density means that the battery can store more energy in a smaller space. For residential applications, where space may be limited, choosing a battery with high energy density is often preferable. Battery life is another important factor, as it determines how long the battery will last before needing replacement. Depending on your specific requirements, you may need to balance energy density and longevity.

– **Cost-Effectiveness**: The initial cost of the battery storage system is an important consideration, but it is also crucial to consider the long-term costs. Different battery technologies have different upfront costs, and some may require more maintenance than others. Lithium-ion batteries, for example, may have a higher initial cost but tend to have lower maintenance costs and longer lifespans, making them a cost-effective choice in the long run.

– **Safety and Reliability**: Safety is a critical consideration when choosing an energy storage solution. Lithium-ion batteries are generally considered safe, but they do have a risk of thermal runaway if not properly managed. LFP batteries, on the other hand, offer enhanced thermal stability and are less prone to overheating. It is essential to choose a battery that meets all relevant safety standards and has an effective Battery Management System (BMS) to ensure safe and reliable operation.

Applications of Energy Storage in Australia

Battery storage solutions are being widely adopted across Australia in both residential and commercial settings. Here are some key examples of how energy storage is being used:

– **Residential Energy Storage**: Many Australian households are using energy storage systems to maximize the value of their solar power systems. By storing excess solar energy, homeowners can reduce their dependence on the grid and save money on electricity bills. In some cases, residential battery storage can also provide backup power during outages, ensuring that critical appliances remain operational.

– **Commercial Energy Management**: Businesses are increasingly adopting energy storage solutions to manage their energy usage more efficiently and reduce costs. By storing energy during off-peak times and using it during peak hours, businesses can take advantage of lower energy rates and avoid expensive peak charges. This can result in significant cost savings and improved energy efficiency.

– **Remote and Rural Areas**: In remote and rural areas, energy storage plays a vital role in ensuring access to reliable electricity. Many of these areas are off-grid and rely on renewable energy sources such as solar or wind. Battery storage systems allow these communities to store energy when it is available and use it as needed, providing a reliable and sustainable energy solution.

Challenges and Recommendations for Purchasing Energy Storage Solutions

While the benefits of battery storage are clear, there are also several challenges that buyers may face when purchasing energy storage solutions. Here are some common challenges and recommendations for overcoming them:

– **Import and Supplier Selection**: Sourcing batteries can be challenging due to import restrictions, supplier reliability, and the availability of certified products. It is important to work with reputable suppliers who provide certified, high-quality products. Make sure the supplier offers all the necessary certifications, such as UL, CE, and RCM, to ensure compliance with safety and performance standards.

– **Quality Assurance and Certifications**: It is crucial to select a supplier that provides certified products that meet international quality standards. These certifications are an indication of the battery’s safety, performance, and compliance with environmental regulations. Always verify the certifications provided by the supplier to avoid issues down the line.

– **Long-Term Partnership and After-Sales Support**: Establishing a long-term relationship with a trusted supplier can offer significant advantages, such as reliable after-sales support and access to the latest technology. Choose suppliers who provide comprehensive support, including installation guidance, system optimization, and warranty services. After-sales support is crucial for ensuring that your energy storage system continues to perform optimally.

Himax Electronics Advantages

Himax Electronics is a leader in the energy storage market, offering innovative battery solutions that meet the diverse needs of Australian buyers. With extensive experience in the industry and a commitment to quality, Himax provides energy storage systems that deliver superior performance, safety, and reliability.

– **High-Quality and Efficient Solutions**: Himax’s energy storage solutions are designed to meet the highest standards of quality and efficiency. Whether for residential, commercial, or industrial applications, Himax batteries offer a range of solutions that ensure reliable energy storage with minimal maintenance.

– **Technical Expertise and Support**: Himax’s team of experts works closely with customers to provide tailored solutions that meet specific needs. From initial consultation to after-sales service, Himax provides comprehensive support, ensuring that customers receive the best possible energy storage experience.

– **Commitment to Australian Buyers**: Himax is dedicated to supporting Australian buyers with energy storage solutions that comply with local standards and meet the unique requirements of the Australian market. By offering customized solutions and robust customer support, Himax ensures that customers can make the most of their energy storage investment.

About Himax Electronics

Himax Electronics is a leading provider of advanced battery storage solutions, specializing in lithium-ion and other innovative technologies. With a strong focus on quality, reliability, and customer satisfaction, Himax has established itself as an industry leader in energy storage systems. The company’s extensive experience in battery research and development allows it to provide customers with solutions that are both cutting-edge and dependable.

Himax’s mission is to deliver energy solutions that help customers achieve greater energy independence, efficiency, and sustainability. With a commitment to innovation and customer support, Himax continues to push the boundaries of what is possible in the energy storage industry, providing Australian buyers with the best in energy storage technology.

Conclusion

Choosing the right battery storage solution is critical for maximizing the benefits of renewable energy and achieving energy independence. By understanding the latest trends in battery technology and considering factors such as energy density, cost-effectiveness, and safety, Australian buyers can make informed decisions that meet their energy needs.

Working with a trusted supplier like Himax Electronics ensures that you receive high-quality, reliable, and efficient energy storage solutions. Himax’s commitment to quality, technical expertise, and customer support makes it the ideal partner for anyone looking to invest in energy storage. With the right solution, Australian households and businesses can achieve significant cost savings, improved energy efficiency, and a more sustainable future.