Introduction

In industries that demand high power and energy density—such as drones, electric vehicles, and power tools—choosing the right battery is crucial. Lithium Polymer (LiPo) batteries have emerged as the preferred choice for these high-demand applications due to their outstanding performance, lightweight design, and versatility. This guide will explain why LiPo batteries are the top choice for bulk buyers in these industries, and how they can meet the demanding requirements of modern high-power applications.

1. The Advantages of LiPo Batteries

High Energy Density

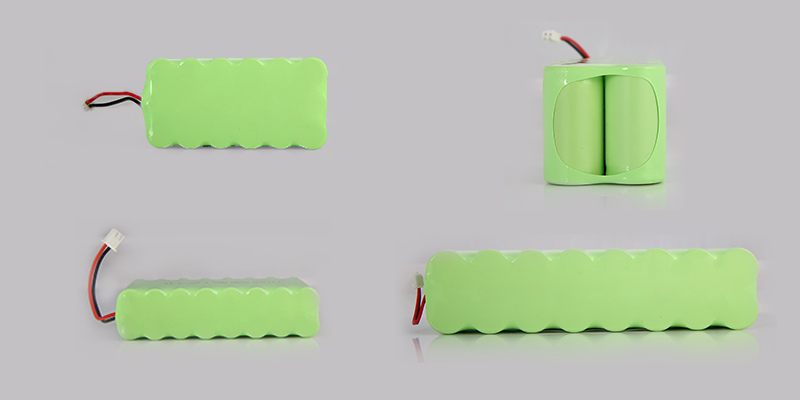

One of the primary advantages of LiPo batteries over traditional options like Nickel-Metal Hydride (NiMH) and lead-acid batteries is their superior energy density. LiPo batteries can store more energy in less space, allowing for a smaller form factor without compromising on power. This makes them particularly useful in applications where both size and energy output are critical, such as in drones and electric vehicles (EVs).

For bulk buyers, the high energy density of LiPo batteries means more efficient storage and longer-lasting performance, reducing the need for frequent replacements and improving the overall cost-effectiveness of their investment.

Lightweight Design

LiPo batteries are renowned for their lightweight design, which is one of the key factors driving their adoption in high-power applications. Their ability to deliver high energy output while keeping the weight down is especially beneficial in industries such as drone manufacturing and remote control (RC) vehicles, where weight reduction can drastically improve performance and efficiency.

In electric vehicles, the weight of the battery pack is a crucial factor affecting the overall vehicle weight and energy consumption. The lighter the battery, the longer the vehicle can run on a single charge. For bulk buyers in industries like EV manufacturing, this means better product performance and greater appeal to consumers.

Higher Discharge Rate

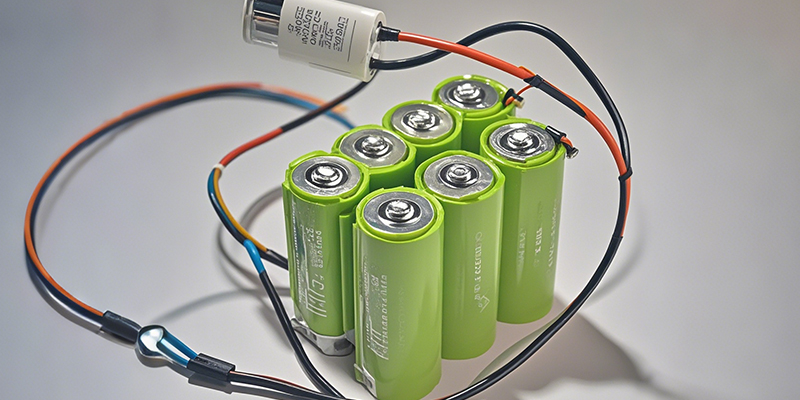

LiPo batteries can provide a higher instantaneous discharge rate, making them ideal for applications that require bursts of power, such as power tools, drones, and RC cars. In these scenarios, a high discharge rate allows the battery to deliver significant amounts of energy quickly, without overheating or compromising safety.

This feature is particularly valuable for high-performance tools and vehicles where power demands fluctuate rapidly. LiPo batteries can handle these surges in power demand without sacrificing efficiency, making them the go-to choice for bulk buyers in industries that require robust and reliable performance.

Flexible Shape and Size

One of the defining characteristics of LiPo batteries is their ability to be molded into various shapes and sizes, offering a level of design flexibility that other battery chemistries cannot match. This makes them highly adaptable to a wide range of applications, from compact drones to bulky power tools.

For bulk buyers, the ability to customize battery packs to fit specific applications means that they can better meet the requirements of their products and minimize wasted space, improving both the aesthetic and functional design of the device.

2. Safety and Management of LiPo Batteries

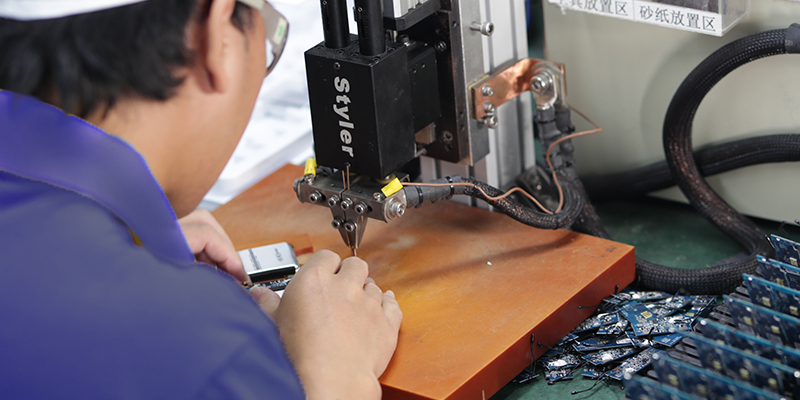

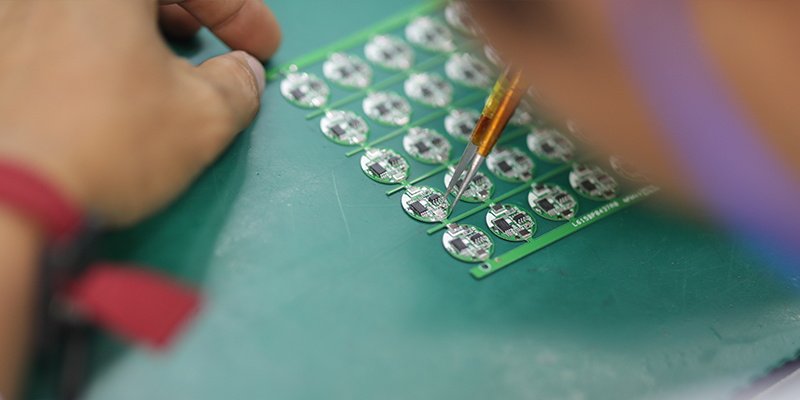

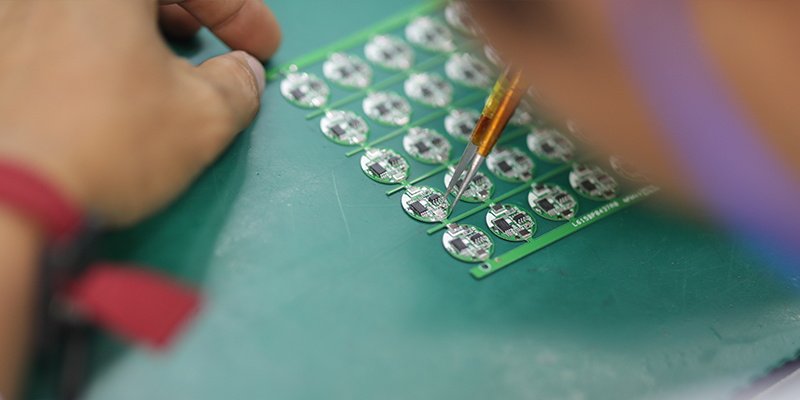

Battery Management System (BMS)

When working with high-power applications, safety is always a priority. LiPo batteries, while offering impressive performance, require a sophisticated battery management system (BMS) to ensure their safe operation. A high-quality BMS can monitor and control the charging, discharging, and overall health of the battery, preventing issues such as overcharging, deep discharging, and short circuits.

For bulk buyers, choosing LiPo batteries with an integrated BMS provides peace of mind that the batteries will perform safely and reliably under demanding conditions.

Overheating and Fire Prevention

One of the concerns with LiPo batteries is the risk of thermal runaway, which can occur if the battery is overcharged, punctured, or exposed to high temperatures. However, modern LiPo batteries are designed with advanced protective features to minimize these risks, including thermal management systems, protective circuits, and fire-resistant materials.

Manufacturers also implement rigorous testing standards to ensure the batteries meet safety requirements. For bulk buyers, ensuring that the LiPo batteries they purchase have these safety features can help reduce the risks of overheating and fire, ensuring both the safety of their end users and the longevity of the battery pack.

3. LiPo Battery Applications in High-Power Industries

Drones

Drones are one of the most well-known applications of LiPo batteries. The lightweight and high-energy density characteristics of LiPo batteries make them ideal for powering drones, especially those used in professional settings such as aerial photography, surveying, and inspection.

LiPo batteries allow drones to maintain longer flight times, carry heavier payloads, and provide consistent power throughout their operation. Bulk buyers in the drone industry prefer LiPo batteries for their ability to meet these demanding performance requirements.

Power Tools

LiPo batteries are increasingly being used in power tools due to their high discharge rates and ability to deliver consistent power output. Whether it’s cordless drills, saws, or lawnmowers, power tools powered by LiPo batteries are able to offer superior performance, longer run times, and faster recharge times.

For bulk buyers in the power tools sector, the shift toward LiPo batteries represents an opportunity to offer products with enhanced capabilities and meet the needs of consumers looking for high-performance, reliable tools.

Electric Vehicles (EVs) and Racing

LiPo batteries are the go-to choice for electric vehicles and racing applications due to their high energy density, light weight, and quick discharge capabilities. In electric vehicles, LiPo batteries allow for longer driving ranges and faster acceleration times, while in racing, their ability to handle extreme power surges makes them essential for high-speed performance.

For bulk buyers in the EV and racing industries, adopting LiPo batteries can translate into superior vehicle performance, longer battery life, and greater consumer satisfaction.

4. Market Trends and the Future of LiPo Batteries

Technological Advancements

As battery technology continues to evolve, LiPo batteries are expected to benefit from new materials and manufacturing techniques that will enhance their performance further. Solid-state battery technology, for instance, could revolutionize the LiPo battery market by offering higher energy densities, improved safety, and faster charging times.

For bulk buyers, keeping an eye on these technological advancements can help them stay ahead of the competition and make informed purchasing decisions.

Growing Market Demand

As electric vehicles, drones, and high-performance tools continue to gain popularity, the demand for LiPo batteries is expected to grow. Bulk buyers should anticipate this increasing demand and consider LiPo batteries as a long-term investment to support the growth of their businesses.

5. Himax Electronics: Your Trusted Partner for LiPo Battery Solutions

Himax Electronics has over 18 years of experience in designing and manufacturing custom LiPo batteries. We specialize in creating tailored solutions for high-power applications, ensuring that our clients receive the perfect battery for their specific needs.

Custom Solutions

At Himax Electronics, we understand that every application is unique. That’s why we offer fully customized LiPo battery packs, built to meet the specific requirements of your industry. Whether you need batteries for drones, power tools, or electric vehicles, we provide the flexibility and performance you need.

Free Samples and Solution Design

We offer free battery samples and comprehensive solution design services to help you evaluate the performance of our products before committing to a bulk order.

Pre-Sales Quality Control and After-Sales Support

Our commitment to quality extends throughout the entire customer journey. We implement rigorous pre-sales quality control processes to ensure our batteries meet the highest standards. Additionally, our dedicated after-sales support team is available to assist with any questions or concerns.

6. Conclusion

LiPo batteries offer unmatched advantages in high-power applications, including drones, electric vehicles, and power tools. Their high energy density, lightweight design, and superior performance make them the go-to choice for bulk buyers in these industries.

At Himax Electronics, we provide customized LiPo battery solutions that deliver outstanding performance, backed by 18 years of experience and exceptional customer support. Contact us today to learn how we can help meet your battery needs in 2024 and beyond.