Today, battery technology is developing very fast. Many LiFePO4 battery packs are becoming more and more complex. However, we want to ask an important question:

Does real safety come from complex systems, or from simple and smart design?

Our answer is simple design.

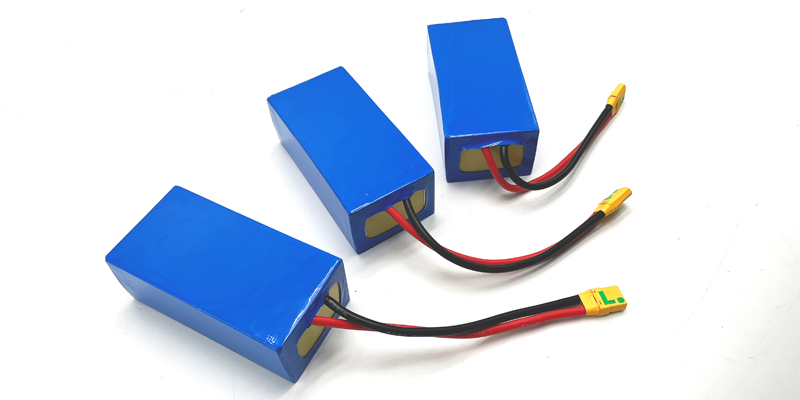

We recently launched a new 12.8V 20Ah LiFePO4 battery pack. Inside, it uses only four large 40135 cells (3.2V 20Ah each) connected in series. This is not a compromise. It is a careful and responsible design choice.

We believe: fewer cells mean higher safety, longer life, and better reliability.

Part 1: Safety Comes from “Less Is More”

The Hidden Risk of Parallel Cells

Many traditional battery packs use many small cells. To get enough capacity, they first connect cells in parallel, then connect groups in series.

This design has hidden risks:

Cell inconsistency

No two cells are exactly the same. Over time, small differences cause internal current between parallel cells. This wastes energy and makes aging faster.

Thermal runaway risk

If one cell overheats, nearby parallel cells may heat up together. The failure can spread very fast, like falling dominoes.

BMS blind spots

The BMS usually checks only the whole group voltage, not each single cell. Early problems are hard to find.

Our Solution: Large Cells, Series Only

We do not use parallel cells.

Our battery uses four large 20Ah cells connected only in series. This brings clear benefits:

No internal current

In a series circuit, all cells carry the same current. There is no internal circulation problem.

Better fault isolation

Each cell is independent. If one cell has an issue, the risk does not spread quickly.

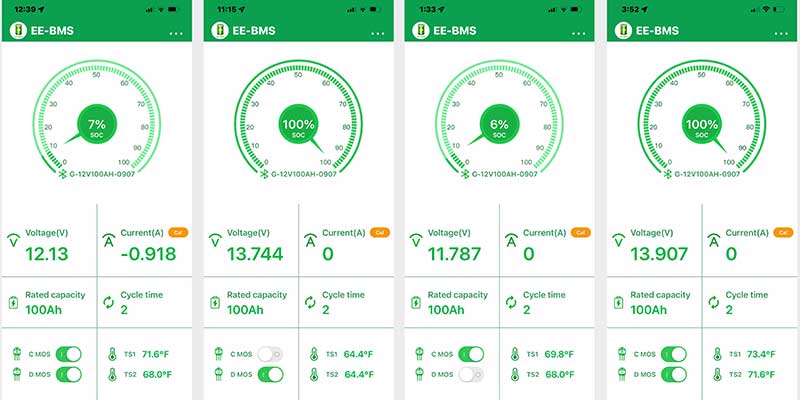

More accurate BMS monitoring

The BMS checks each cell’s voltage and temperature, so small problems can be found early.

In short, we turn a complex system into a clear and safe team, where every cell is visible and controlled.

Part 2: More Benefits of Large Cells

1. Better Use of Space

Many small cells need extra space for holders, connectors, and cooling paths. These parts do not store energy.

Large 40135 cells have a high space efficiency. The battery structure is simpler, so more space is used for energy.

Result:

More energy in the same case

Or a smaller and lighter battery for the same energy

2. Better Consistency, Longer Life

A battery pack is limited by its weakest cell.

Large cells have more stable production quality. Also, it is much easier to match 4 cells than 16 or more small cells.

With good consistency, no parallel stress, and precise BMS balancing, all cells age at the same speed.

This helps the battery reach over 3000 charge cycles and a long calendar life.

3. Higher Reliability, Lower Cost Over Time

Fewer cells = fewer failure points

Less welding, fewer connections, higher reliability.

Simpler BMS work

No complex parallel balancing, better system stability.

Lower total cost

Even if the initial cost is higher, the long life and low maintenance reduce the total cost over time.

Part 3: Wide Range of Applications

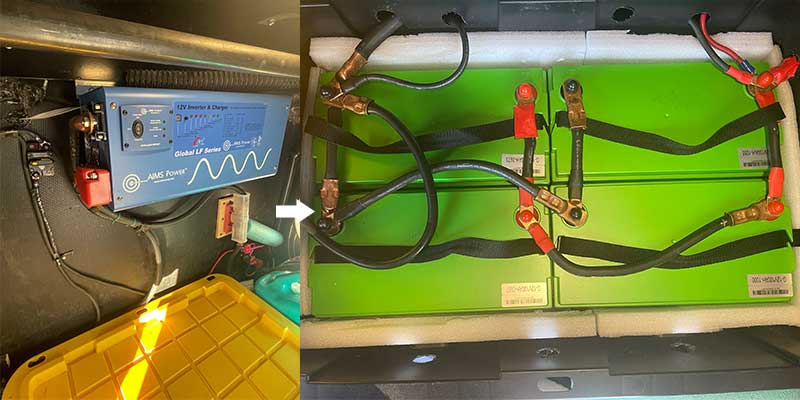

Thanks to its safety, long life, and stability, this 12.8V 20Ah LiFePO4 battery is a perfect replacement for lead-acid batteries.

1. Outdoor and Home Energy

Portable power stations

RV and marine auxiliary power

Home backup power and solar storage

2. Light Electric Vehicles

E-bikes and e-scooters

Electric wheelchairs and mobility scooters

Golf carts and low-speed vehicles

3. Garden and Cleaning Tools

Electric lawn mowers

Cleaning robots and floor machines

4. Commercial and Industrial Use

AGV and mobile robots

Testing instruments and security systems

Emergency lighting and communication backup.

Conclusion: Simple Design for a Safer Future

Making systems more complex is easy. Making them simpler and safer needs real engineering thinking.

By using only four large cells, we focus on what truly matters:

safety, reliability, and long-term performance.

A good battery should work quietly and safely in the background—not become a risk.

If you are looking for a safe, long-life, and reliable energy solution, we are happy to discuss with you.