What Is an AED Battery and Why Does It Matter?

How AEDs Work and Why They’re Essential

An AED, or Automated External Defibrillator, is a portable gadget designed to help people experiencing sudden cardiac arrest. It delivers an electric shock to restart a heart’s normal rhythm, earning it the nickname “life-saving hero” in emergencies. Studies show that using an AED within the first few minutes of cardiac arrest can dramatically boost survival rates. But here’s the catch: it only works if the device is powered up and ready, and that’s where the battery comes in.

The Critical Role of AED Batteries

The AED battery powers the device, keeping it on standby and ready to deliver a shock when needed. From routine self-checks to actual use, the battery’s performance affects how fast and effectively the AED responds. A weak or aging battery could mean the device won’t turn on—or worse, fails mid-emergency. That’s why picking a top-notch battery isn’t just a good idea; it’s a must.

Battery Life and Its Link to Safety

Battery life is a big deal when judging an AED battery’s quality. Typically, these batteries last 2 to 5 years in standby mode, though how long they actually hold up depends on storage and usage. A long-lasting, stable battery cuts down on replacements and ensures your AED won’t let you down due to power issues. Many AEDs rely on lithium-ion batteries for their high energy density and reliability, but you’ve got to choose carefully to avoid safety risks from poor-quality options.

Key Factors to Understand About AED Batteries

Battery Life and Standby Duration

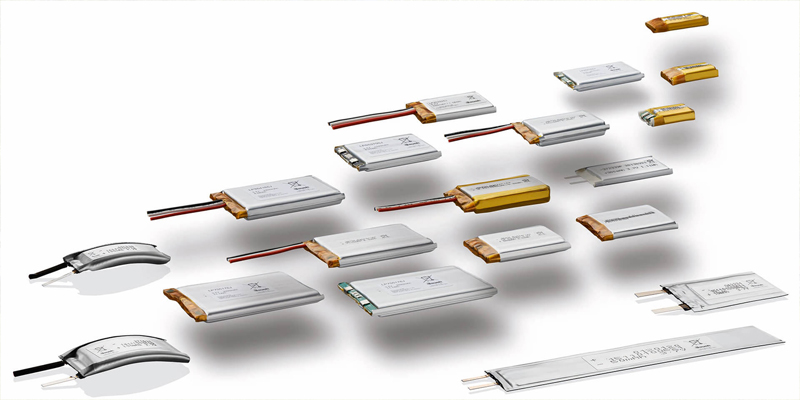

AED batteries usually offer a standby life of 2 to 5 years, depending on the brand and model. For instance, batteries from Philips or Himax can last up to 4 years, while some premium models stretch even further. This standby time dictates how often you’ll need to swap them out. If your AED sits in a low-use spot like a home or office, a longer standby life is key. For devices that get frequent self-tests or use, you’ll want to keep an eye on the battery’s real-world lifespan.

Compatibility

Not every battery fits every AED. Before buying, double-check that the battery matches your specific AED model. Mixing incompatible specs—like using a Philips HeartStart battery in a ZOLL AED—could leave your device dead in the water. Peek at your AED’s manual or call the manufacturer to confirm you’re getting the right fit.

Quality and Certifications

A battery’s quality ties directly to your AED’s safety. Look for batteries with CE (European Conformity) or FDA (U.S. Food and Drug Administration) certifications—these stamps mean they meet tough safety and performance standards. Lithium-ion batteries, a common choice, owe their durability and stability to solid manufacturing and materials. Stick to certified options to dodge risks from shoddy products.

Environmental Resilience

AEDs might end up in all sorts of places—think hot car trunks or damp outdoor spots. A good battery needs to handle these conditions. Top-tier batteries stay reliable in extreme temps (usually -4°F to 122°F) and high humidity. Check the product specs for its operating range to make sure it suits where you’ll keep your AED.

Your Practical Guide to Buying AED Batteries Online

Figure Out What You Need

Before you hit “buy,” nail down your needs. Think about your AED model, how often it’s used, and where it’s stored. A public-space AED might call for a tougher battery than one at home. Knowing this narrows your options and makes shopping smoother.

Compare Brands and Prices

The market’s full of AED battery brands like Philips, ZOLL, and Himax, each with its strengths. Philips is a go-to for dependability, ZOLL shines with long-life designs, and Himax offers solid bang for your buck. Prices typically range from $70 to $200. Weigh your budget against the specs to pick the best match.

Check User Reviews

Online reviews are gold when sizing up a battery’s performance. Look at what other buyers say about lifespan, ease of installation, and real-world use. If a battery keeps getting flagged for “short standby time” or “tricky setup,” steer clear. A mix of reviews gives you a clearer picture of what to expect.

Shop from Trusted Sources

To avoid fakes, buy straight from brand websites or well-known platforms like Amazon. These spots usually guarantee authenticity and solid customer support. Always check the seller’s creds and product certifications to ensure you’re getting the real deal.

Tips to Extend Your AED Battery’s Life

Storage Smarts

Where you keep your battery matters. Store your AED and its battery in a cool, dry place—high heat or moisture can cut its life short. Temps above 104°F can speed up lithium-ion battery wear, and excess humidity might cause shorts. Aim for a sweet spot of 59°F to 77°F.

Routine Checks

Most AEDs run self-tests and signal battery status with lights or beeps. Check your device monthly to confirm the battery’s good to go. If you spot a low-battery alert, swap it out ASAP. Jot down the install date so you’re ready when it nears its expiration.

Be Prepared for Emergencies

Keep a spare battery on hand for unexpected situations, stored separately from the main one to avoid both aging out together. Use its original packaging or a sealed bag to shield it from the elements.

How to Replace Your Battery

Swapping an AED battery is usually a breeze. Pop open the compartment, pull out the old battery, slide in the new one, and close it up. Steps vary by model, so flip through your manual to get it right.

FAQs

-

Will my AED warn me when the battery’s dying? Yup, most AEDs beep or flash when the battery’s low or expired.

-

What do I do with an old battery? Drop it off at a recycling center—don’t toss it in the trash—to keep things eco-friendly.

What’s New for AED Batteries in 2025

Tech’s moving fast, and by 2025, AED batteries might pack more efficient lithium-ion designs with better energy density and longer standby times. Some brands could roll out smart batteries with remote power monitoring. Keep an eye on these updates for cutting-edge options.

Discover Himax’s AED (Lithium-Ion) Batteries

Your AED battery is the key to keeping it safe and reliable. From lifespan and compatibility to quality certifications, every detail shapes how it performs in a crisis. With this guide, you can pinpoint your needs, compare brands, and buy a high-performance battery from a trusted source. Plus, smart maintenance stretches its life, giving you extra peace of mind. Check out Himax-Electronics’ website for top-quality AED battery options. Act now—equip your AED with a long-lasting, dependable battery to protect you and your loved ones every step of the way!