Lithium ion batteries presently are the ubiquitous source of electrical energy in mobile devices, and the key technology for e-mobility and energy storage. Massive interdisciplinary research efforts are underway both to develop practical alternatives that are more sustainable and environmentally friendly, and to develop batteries that are safer, more performing, and longer-lasting—particularly for applications demanding high capacity and very dense energy storage.

Understanding degradations and failure mechanisms in detail opens opportunities to better predict and mitigate them.

In a new study, a team of researchers led by the Institute of Interdisciplinary Research of the CEA, the Institut Laue Langevin (ILL) and the European Synchrotron (ESRF) in collaboration has examined Lithium ion batteries during their lifetime using state-of-the-art, non-intrusive imaging techniques available at neutron and X-ray sources.

The team’s paper is published in the journal Energy & Environmental Science.

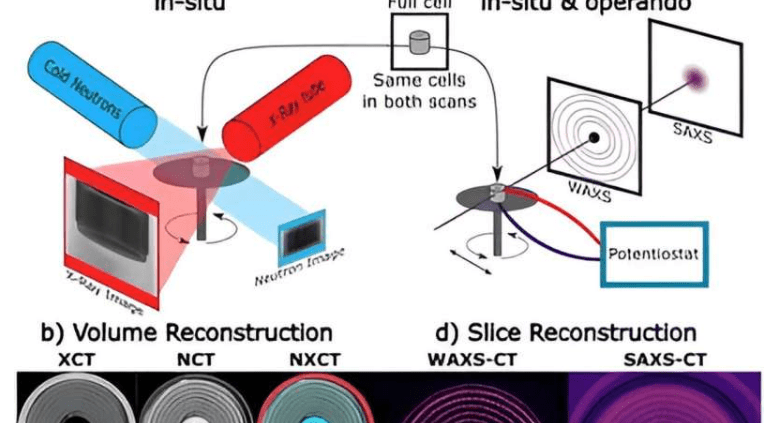

Neutrons and photons are largely complementary. Neutrons are particularly good at seeing lithium and other light elements, while X-rays are sensitive to heavy elements, such as nickel and copper. Their sophisticated combination allowed the researchers to gain multidimensional information on the components and elements inside working battery cells.

The team identified macroscopic deformations in the wound structure of the copper current collector. The deformed areas already existed in fresh battery cells that had only gone through the initial activation cycle (the first charging-discharging cycle). Further investigations revealed that these defects were due to local accumulations of silicon occurring during electrode manufacturing. Upon activation, the largest agglomerates expanded heavily, which led to deformations in the current collector, wasting capacity before the cell ever went into use.

It was possible to determine how large these accumulations must be to become a problem: cell structure and functioning is compromised for silicon agglomerations with a size above 50 microns. This is crucial information for both quality control and future developments. Erik Lübke, Ph.D. student at ILL and the main author of the study, summarizes, “In fact, resources are wasted when this happens, and we have quantified the effects and understood their causes.”

Full-field, high-resolution 3D transmission tomography enabled the inspection of the entire volume of the battery cell, revealing the presence of a number of defect features. These were more closely investigated at selected cross-sectional 2D slices.

The neutron tomography scans (with simultaneous low intensity X-ray computed tomography scans) were carried out at the NeXT instrument of the ILL. Synchrotron X-ray tomography scans of the very same cells were then measured at the ESRF using two beamlines, BM05 and the high-energy ID31 beamline for phase-contrast and scattering tomography respectively.

At NeXT, 3D high resolution neutron tomography is coupled with X-ray tomography to image the entire cell. Erik Lübke explains, “X-rays give the basic structure, making it possible to know exactly where we are when we use neutrons to examine the spatial distribution of lithium in detail,” benefiting from “the best neutron resolution you can get anywhere in the world.”

Selected parts of the cell were then examined in further detail using several different X-ray tomography techniques at the ESRF high-energy beamlines. Acquiring data during the battery charging process (a so-called operando experiment) made it possible to gather more information about the reaction dynamics in the defective regions: Lithium diffusion is partly blocked there, and even when most of the cell is fully charged these areas remain without lithium in their center.

To ensure the industrial relevance of the results, the team tested cylindrical silicon-based lithium ion battery cells manufactured according to industry standards. Cells of this format are in commercial use in small electronic devices such as medical sensors, headphones, and smart devices. However, the size was reduced for a better compatibility with the experimental requirements. Both fresh cells and aged ones (cycled over 700 times with roughly 50% remaining capacity) were imaged, in charged and discharged states. The different techniques were applied to the very same cells.

More information: Erik Lübke et al, The origins of critical deformations in cylindrical silicon based Li-ion batteries, Energy & Environmental Science (2024). DOI: 10.1039/D4EE00590B

Journal information: Energy & Environmental Science

Provided by Institut Laue-Langevin