NiMH (Nickel-Metal Hydride) batteries are a go-to choice for many household gadgets and portable electronics thanks to their eco-friendly nature, rechargeability, and wide range of uses. From cordless phones to digital cameras, NiMH batteries deliver the high capacity and reliability we need for daily life. But if you’re not familiar with them, you might be wondering: How do NiMH batteries work? What types are available? Where are they best used, and how do you pick the right one? This article will break it all down for you from both an educational and practical perspective, helping you understand NiMH batteries’ workings, types, applications, and offering the latest 2025 buying tips to make choosing the perfect NiMH battery a breeze.

What You Need to Know About NiMH Batteries

Understanding how NiMH batteries work is the first step to buying and using them effectively. Here’s a quick look at the essentials:

What Are NiMH Batteries?

NiMH batteries are rechargeable batteries that use nickel oxide for the positive electrode (cathode) and a hydrogen-absorbing alloy for the negative electrode (anode), with a potassium hydroxide solution as the electrolyte. Unlike older NiCd (Nickel-Cadmium) batteries, NiMH batteries don’t contain toxic cadmium, making them more eco-friendly and widely used in both home and industrial devices.

How They Work

NiMH batteries generate electricity through an electrochemical reaction between the nickel oxide cathode and the hydrogen-absorbing alloy anode. During discharge, the alloy in the anode releases hydrogen ions, which travel through the electrolyte to the cathode, reacting with the nickel oxide to produce water and release electrons, creating an electric current. When charging, this process reverses: hydrogen ions are stored back in the alloy, converting electrical energy into chemical energy. NiMH batteries typically have a nominal voltage of 1.2V, and multiple cells can be connected in series for higher voltage needs.

Pros and Cons

NiMH batteries come with some clear advantages. For starters, they’re free of heavy metals like cadmium, so their production and recycling are more environmentally friendly, aligning with today’s green living trends. They also have a high capacity (ranging from 800mAh to 2700mAh) and can handle high current output, making them great for power-hungry devices. However, they do have downsides: they have a high self-discharge rate (20%-30% per month), meaning they lose charge quickly if left unused, and they suffer from a memory effect—if you charge them before they’re fully discharged, their capacity might decrease over time.

How to Charge NiMH Batteries

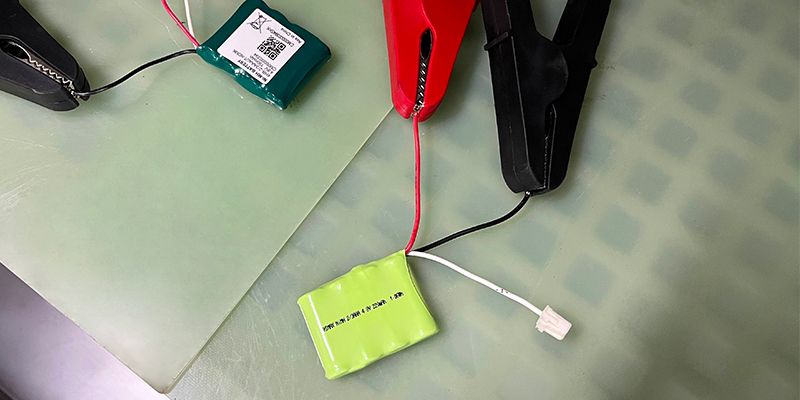

When charging NiMH batteries, it’s best to use a dedicated NiMH battery charger to ensure a safe and efficient process. These chargers typically use a constant current mode and switch to a trickle charge as the battery nears full capacity to prevent overcharging. Charging usually takes 6-8 hours, depending on the battery’s capacity and the charger’s output—for example, a 2000mAh battery charged at 200mA will take about 10 hours. To reduce the memory effect, it’s a good idea to do a full charge-discharge cycle every 1-2 months, draining the battery to near 0% before charging it back to 100%. Also, store them in a cool, dry place to avoid high temperatures or humidity, which can harm their performance. If you want to know how long NiMH batteries can last, you can click here to view the content.

Types of NiMH Batteries and Their Features

NiMH batteries come in different types based on their performance and intended use, each with unique features for specific scenarios.

Standard NiMH Batteries

Standard NiMH batteries are the most common type, typically available in AA or AAA sizes with capacities ranging from 800mAh to 2700mAh. They’re great for household devices like cordless phones, remote controls, and electric toys. These batteries are budget-friendly and have a decent capacity for everyday needs, but their high self-discharge rate makes them better suited for devices you use frequently.

Low Self-Discharge NiMH Batteries (LSD Ni-MH)

Low Self-Discharge (LSD) NiMH batteries are a newer, improved version with a much lower self-discharge rate (only 5%-10% per month). These are perfect for devices you don’t use often, like emergency flashlights or backup remotes, since they can hold most of their charge even after months of storage.

High-Temperature NiMH Batteries

High-temperature NiMH batteries are designed for extreme conditions, performing well in temperatures up to 70°C. They’re ideal for industrial equipment or devices used in hot environments, like certain industrial sensors or outdoor gear. These batteries hold up better in high heat with less performance loss, but they’re pricier and less common in typical household settings.

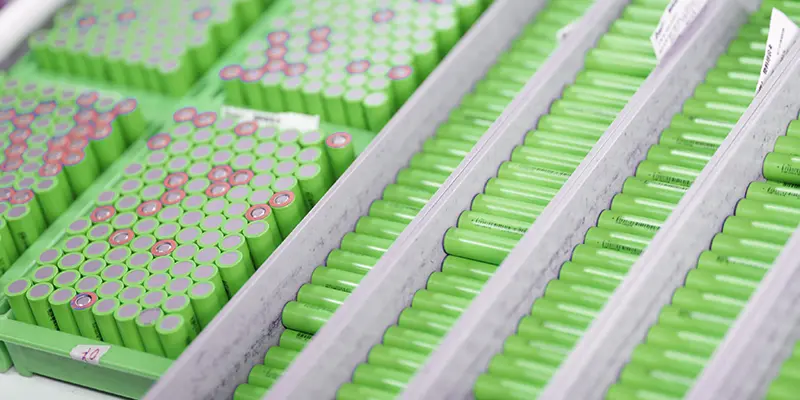

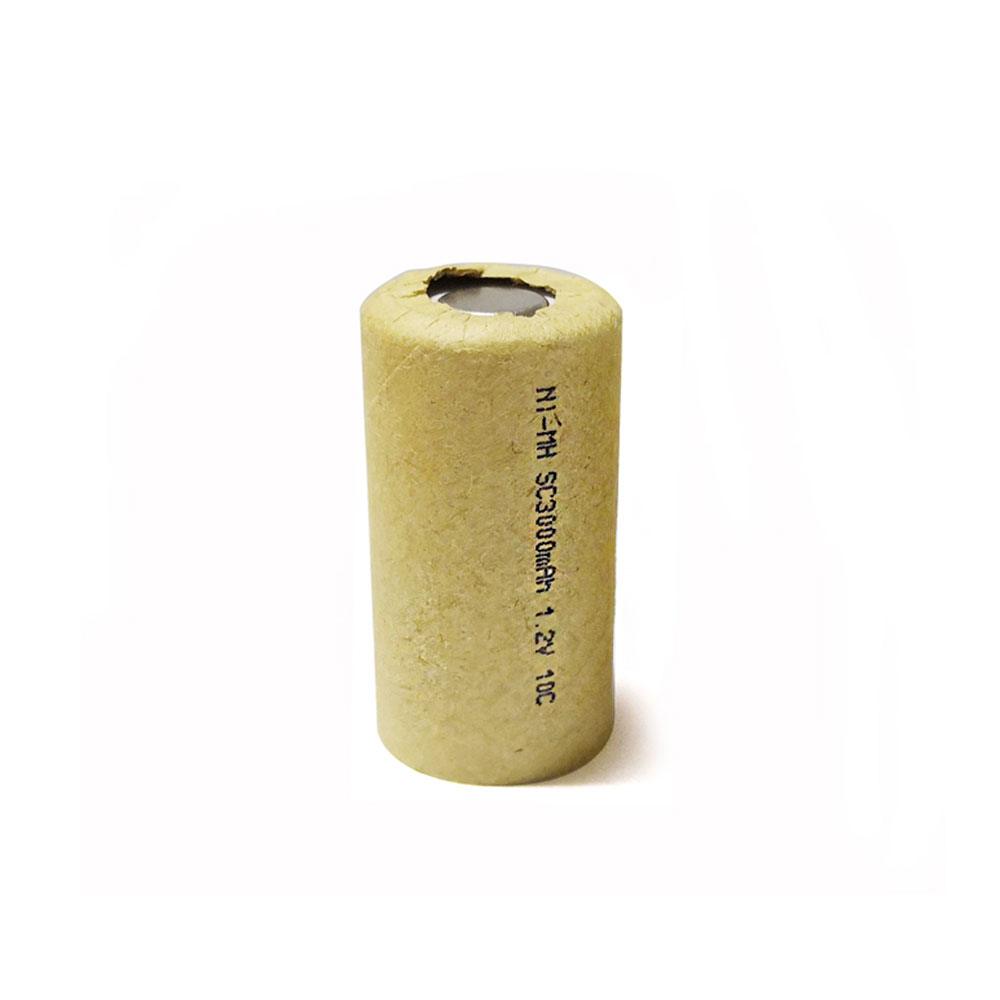

Shape and Form Factors

NiMH batteries come in various shapes, including cylindrical (like AA or AAA batteries) and rectangular (like battery packs). Cylindrical batteries are compact and fit well in portable devices, while rectangular packs are often used in applications requiring multiple cells in series, such as hybrid electric vehicles (HEVs) or industrial backup power systems. These different forms cater to a range of device designs, so you can pick the right type based on your equipment’s specs.

Where NiMH Batteries Are Used

Thanks to their high capacity and eco-friendly design, NiMH batteries are used in a variety of settings. Here are some common applications:

Household Devices

NiMH batteries are widely used in household gadgets like cordless phones, remote controls, electric toys, and wireless keyboards or mice. These devices often need a strong current output, and NiMH batteries provide steady power to keep them running for long periods.

Portable Electronics

NiMH batteries shine in portable electronics, too. Devices like digital cameras, handheld gaming consoles, and portable radios often use AA or AAA NiMH batteries. They deliver reliable battery life to meet the high power demands of these gadgets, making them great for travel or photography on the go.

Industrial and Transportation

NiMH batteries play a big role in industrial and transportation applications. For example, hybrid electric vehicles (HEVs) often use NiMH battery packs as a power source because of their high capacity and durability for long-term use. They’re also used as backup power in industrial equipment, ensuring devices can still operate during power outages.

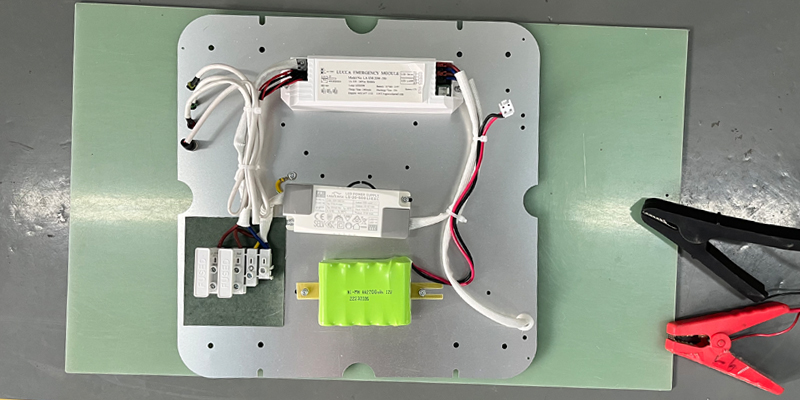

Emergency and Outdoor Gear

Low self-discharge NiMH batteries are perfect for emergency and outdoor gear, like flashlights, emergency lights, and portable GPS devices. They can hold a charge for months, ensuring they’re ready to use in urgent situations, whether you’re camping or preparing for a power outage at home.

Education and DIY Projects

For students and DIY enthusiasts, NiMH batteries are a great choice for experiments and projects. In robotics builds or classroom experiments, AA NiMH batteries can power motors or circuit boards. These scenarios often require batteries that are portable and compatible with various setups, and NiMH batteries fit the bill.

Practical Tips for Buying NiMH Batteries

Now that you know how NiMH batteries work, the types available, and where they’re used, how do you pick the right one? Here are some practical tips:

Capacity and Intended Use

Choosing the right capacity is key. For small devices like remote controls, a 1000mAh battery is plenty for daily use. For high-drain devices like digital cameras, go for 2500mAh or higher to ensure longer runtime. When buying, check the battery’s actual capacity to avoid products with inflated claims.

Self-Discharge Rate

The self-discharge rate is a big factor when choosing NiMH batteries. If you’re using them in devices that sit unused for long periods (like an emergency flashlight), opt for low self-discharge (LSD) models to minimize power loss. For frequently used devices, standard NiMH batteries are more cost-effective.

Brand and Certifications

Stick to brands with certifications like CE or RoHS, which show the battery has passed strict quality tests. Reputable brands often have better manufacturing standards and customer support, lowering the risk of getting a faulty product.

Budget Considerations

Your budget matters, too. If you’re on a tight budget (under $50 for a pack), standard NiMH batteries will meet basic needs. If you’ve got more to spend (over $50 per pack), consider low self-discharge or high-temperature models, which offer better performance and durability for specific uses.

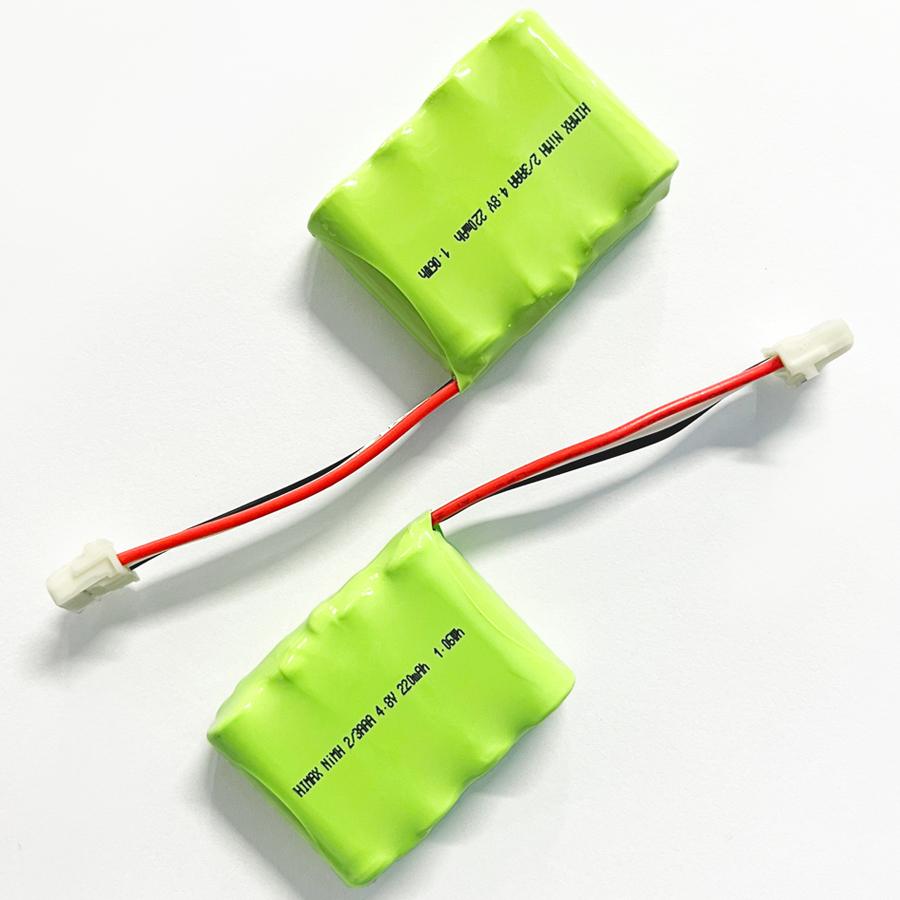

Why Choose HIMAX NiMH Batteries?

HIMAX Electronics is a trusted online retailer specializing in high-quality batteries, known for exceptional performance and top-notch service. We recommend the “HIMAX Rechargeable 1.2V 2000mAh NiMH Battery.” This AA-sized battery with a 2000mAh capacity is perfect for devices like cordless phones, digital cameras, and electric toys. Made with eco-friendly materials and a low self-discharge rate, it delivers reliable power to keep your devices running smoothly. Check out the HIMAX Electronics website to explore their range of NiMH batteries and find the perfect fit for your needs!