At HIMAX Electronics, we understand that the true performance of lithium-ion batteries depends not only on the quality of the cells but also on the Battery Management System (BMS) that governs them. A BMS ensures that the battery operates efficiently, lasts longer, and remains safe throughout its life. Whether you’re developing an electric vehicle (EV), building a solar energy storage solution, or creating advanced robotics, the BMS plays a pivotal role in the overall performance and longevity of your lithium-ion battery pack. In this article, we’ll dive into what makes a good BMS system and how HIMAX Electronics can provide you with the right solution for your needs.

What is a Battery Management System (BMS)?

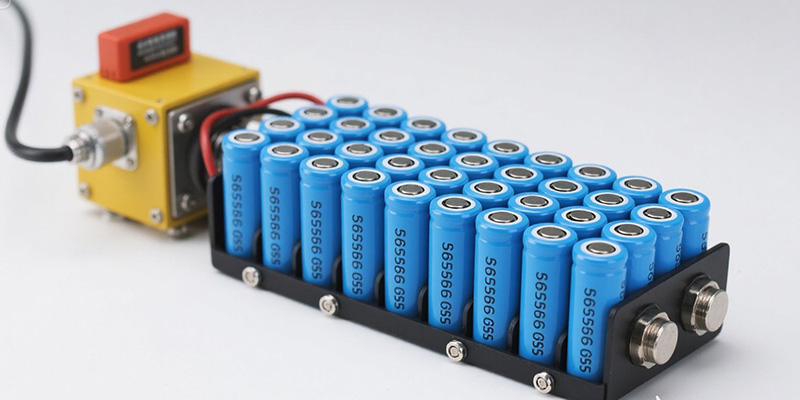

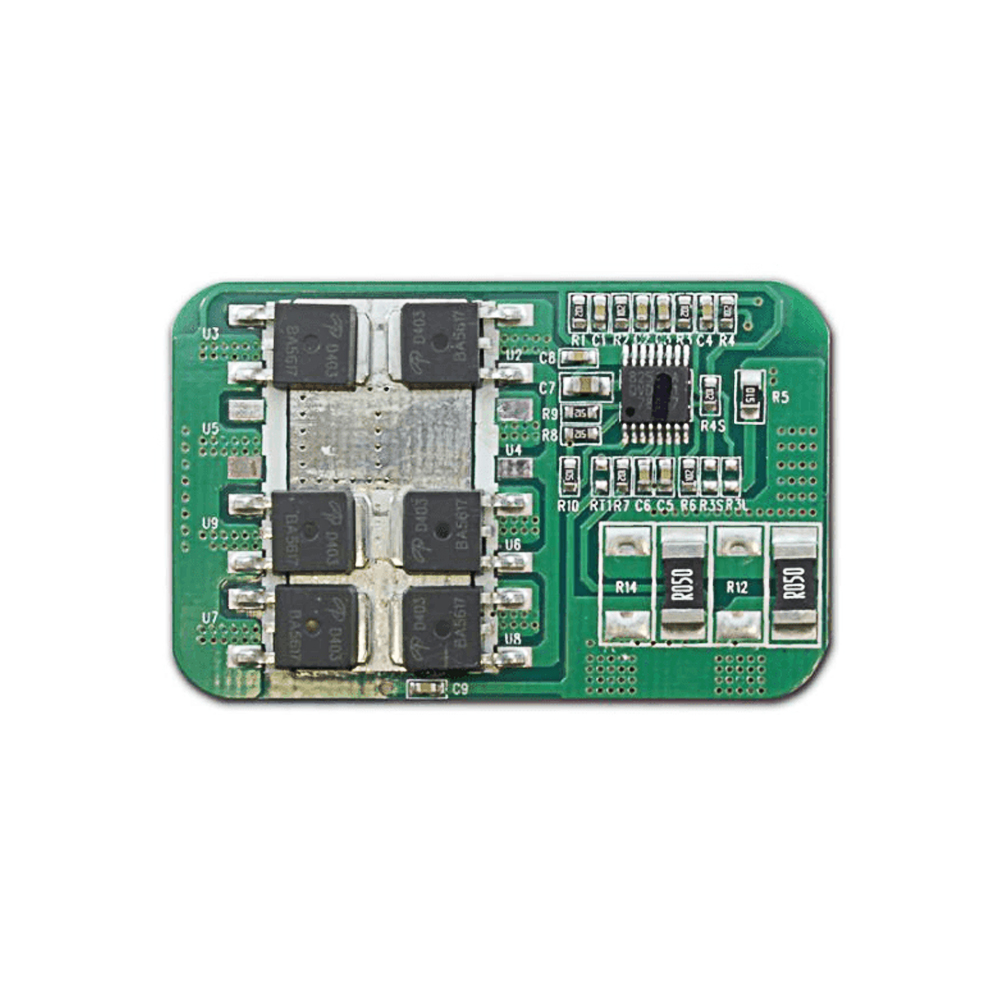

A Battery Management System (BMS) is the controller responsible for overseeing the operation of a lithium-ion battery pack. The BMS plays a critical role in ensuring that the battery operates safely and efficiently by monitoring the key parameters of each cell, such as voltage, current, temperature, and state of charge (SOC). It helps to prevent overcharging, over-discharging, short-circuits, and overheating—all of which can significantly reduce the lifespan of the battery or even lead to dangerous situations.

While many may think of the BMS as just another electronic component, it’s the brains of the operation. In fact, a well-designed BMS can not only improve safety but also maximize performance by balancing the battery pack, optimizing charge cycles, and providing real-time diagnostics.

Key Features of a Good BMS for Lithium-Ion Batteries

Voltage Monitoring at the Cell Level

Lithium-ion cells have a narrow voltage range that is crucial to their performance and safety. Overcharging a cell can cause it to overheat, while undercharging it can lead to irreversible damage. The BMS constantly monitors the voltage of each individual cell in the battery pack to make sure that no cell is charged beyond its safe voltage level or discharged too deeply.

Why It Matters: Accurate voltage monitoring ensures that your battery operates safely and efficiently, preventing the risk of thermal runaway, over-discharge, or over-charge. At HIMAX Electronics, we use advanced monitoring techniques to ensure that each cell within the pack stays within the optimal range for performance and safety.

Current Monitoring (Charge and Discharge)

Current monitoring helps to track the flow of current into and out of the battery during charging and discharging cycles. The BMS ensures that the current does not exceed the battery’s rated limits, preventing overheating and potential damage.

Why It Matters: Excessive charging current can cause cell overheating and reduced efficiency, while over-discharging can damage the battery’s internal structure. By continuously tracking the current flow, our BMS systems prevent such issues and maintain optimal performance over the long term.

Temperature Control and Thermal Management

Lithium-ion batteries can heat up during heavy use, and temperature is one of the most critical factors influencing battery performance and safety. A BMS will typically integrate temperature sensors that monitor the battery pack’s temperature, ensuring that it doesn’t exceed safe thresholds. When the temperature rises too high, the BMS can trigger cooling systems or shut down the battery to prevent overheating.

Why It Matters: If the temperature rises beyond a safe limit, it could lead to thermal runaway, which can cause fires or damage the battery permanently. HIMAX Electronics incorporates advanced thermal management strategies in our BMS solutions, ensuring that your battery remains within safe operating temperatures under all conditions.

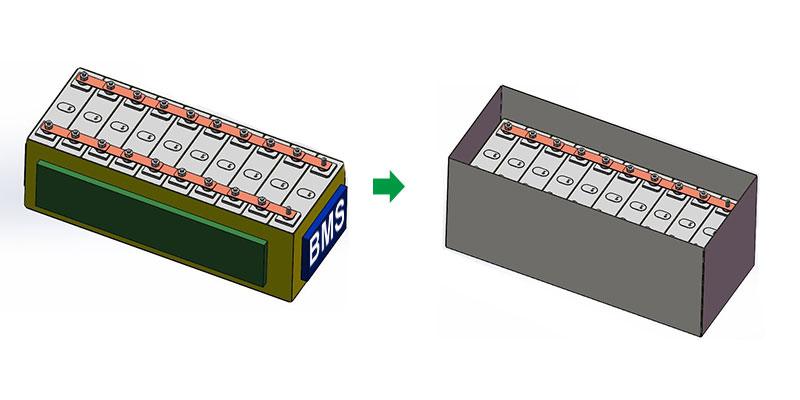

Cell Balancing

Over time, cells in a multi-cell battery pack can become imbalanced. This means some cells may be overcharged while others are undercharged, leading to uneven performance. A good BMS employs cell balancing techniques to ensure that all cells in the battery pack are charged and discharged uniformly.

Why It Matters: Unbalanced cells can cause capacity loss, reduce battery lifespan, and even lead to safety risks. With HIMAX’s BMS, we use both passive and active balancing methods to ensure that all cells in the pack perform optimally, leading to better efficiency and longer battery life.

State of Charge (SOC) Estimation

The State of Charge (SOC) tells you how much energy is remaining in the battery, typically displayed as a percentage. The BMS continuously monitors the SOC to prevent over-discharge, which can damage the battery cells.

Why It Matters: Accurate SOC estimation ensures that users always have a clear idea of how much charge is left, preventing situations where the battery runs out unexpectedly. HIMAX’s BMS systems use sophisticated algorithms to deliver accurate SOC readings, ensuring reliable performance and avoiding unnecessary battery wear.

State of Health (SOH) Monitoring

As a battery ages, its internal resistance increases, and its capacity decreases. The BMS tracks the State of Health (SOH) of the battery over time, providing important insights into how much usable life is left in the pack.

Why It Matters: Monitoring SOH allows you to take proactive measures to replace or maintain the battery before it reaches a critical point. This can help to avoid unexpected downtime and costly repairs, ensuring that your battery continues to deliver peak performance for as long as possible.

Overcharge and Over-discharge Protection

Both overcharging and over-discharging can significantly damage a lithium-ion battery. The BMS actively monitors the voltage of each cell and will automatically disconnect the battery from the load or charger if it detects an overcharge or deep discharge situation.

Why It Matters: This protection is crucial for the longevity and safety of the battery pack. By preventing overcharge or over-discharge, our BMS solutions help to maximize the usable life of your battery and reduce the risk of dangerous incidents like fires or explosions.

Fault Detection and Alerts

A high-quality BMS is equipped with fault detection systems that can identify problems such as short circuits, abnormal voltage readings, or temperature fluctuations. When an issue is detected, the BMS immediately takes action—either by shutting down the system or sending an alert to the user.

Why It Matters: Early detection of faults helps prevent serious damage to the battery pack, system, or equipment. HIMAX’s BMS systems provide real-time alerts and diagnostics, allowing you to respond quickly to any issues.

Communication and Diagnostics

The BMS should provide continuous communication with external systems like chargers, controllers, and monitoring platforms. This ensures that the battery can be controlled remotely, and its performance can be monitored in real-time.

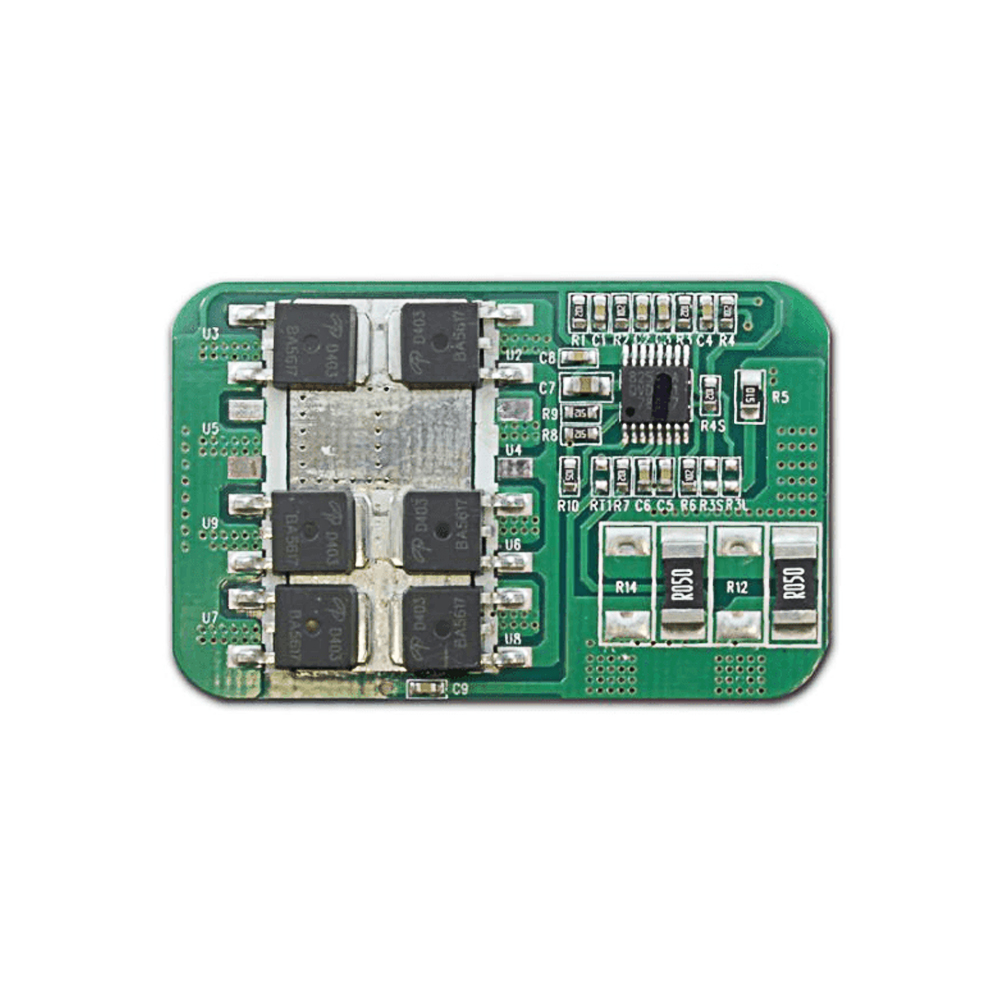

Why It Matters: Communication enables better management of the battery’s performance, especially in complex systems. At HIMAX Electronics, we integrate CAN bus, SMBus, and UART communication protocols into our BMS systems, allowing for seamless integration with other devices and remote monitoring.

Why HIMAX Electronics is Your Trusted Partner for BMS Solutions

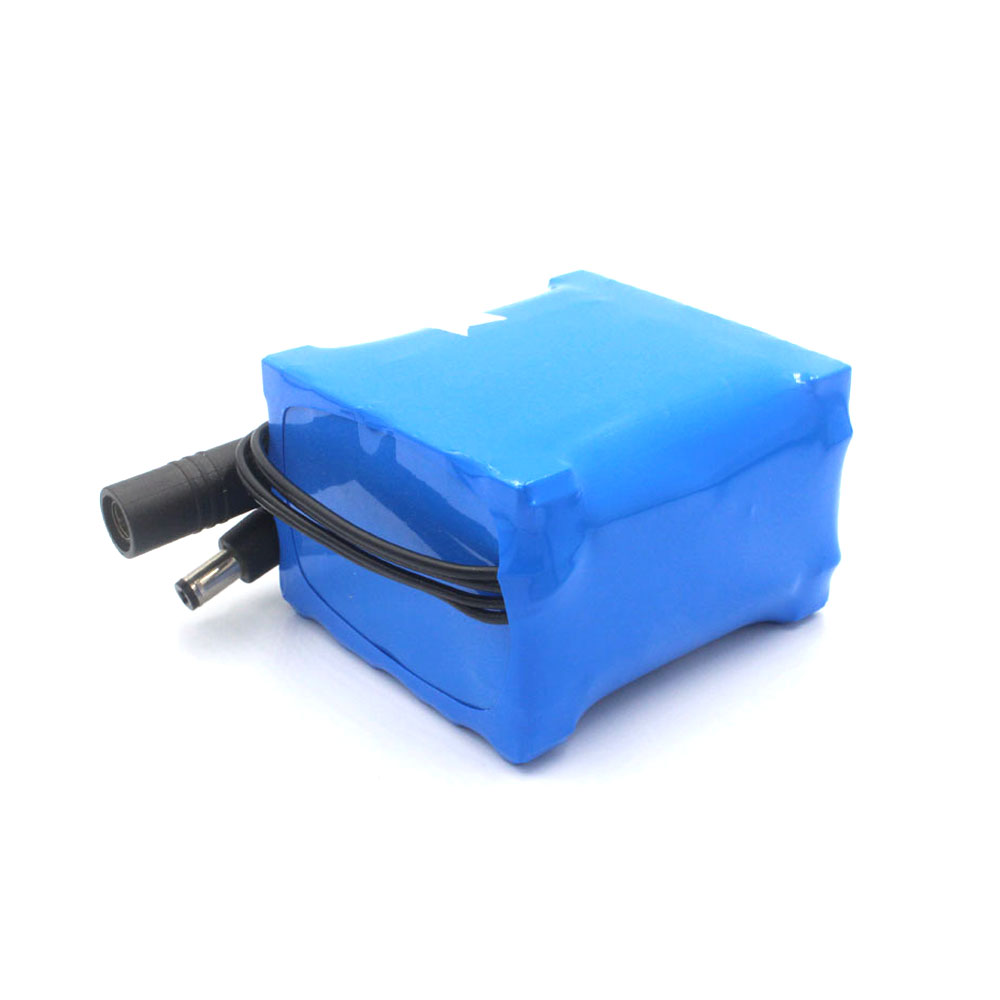

At HIMAX Electronics, we specialize in providing high-performance Battery Management Systems (BMS) that meet the unique needs of various applications, from electric vehicles (EVs) to energy storage systems and robotics. With years of experience in the field of lithium-ion batteries, we deliver BMS solutions that prioritize safety, performance, and longevity.

What Sets Us Apart:

Customization: We offer customized BMS solutions designed specifically for your project’s requirements, whether you’re building an electric vehicle or a renewable energy storage system.

Safety-First Approach: Safety is at the core of our design philosophy. Our BMS systems incorporate multiple safety protocols to ensure that your batteries are always operating within safe parameters.

High-Quality Components: We use only the best materials and technology to build our BMS, ensuring that every system is reliable, accurate, and efficient.

Real-Time Monitoring and Diagnostics: With advanced real-time diagnostics and communication capabilities, our BMS solutions offer comprehensive control and monitoring, allowing for the best possible battery performance.

Applications of Our BMS Solutions

Electric Vehicles (EVs): Ensuring safety, efficiency, and long-range performance.

Robotics: Reliable power management for precision equipment.

Renewable Energy: Optimizing energy storage in solar and wind applications.

Energy Backup Systems: Providing uninterrupted power to critical systems.

Power Tools: Ensuring consistent, long-lasting power for industrial and consumer tools.

Conclusion

A well-designed Battery Management System (BMS) is the key to ensuring that your lithium-ion batteries perform at their best and last as long as possible. At HIMAX Electronics, we provide cutting-edge BMS solutions that ensure your battery systems are safe, efficient, and reliable. With our expertise and commitment to quality, we help you get the most out of your energy storage systems, no matter the application.