Definition of Series and Parallel Connection of Lithium Batteries

Definition of Series and Parallel Connection of Lithium Batteries

Due to the limited voltage and capacity of the single battery cell, the series and parallel connection is needed in the actual use to obtain higher voltage and capacity, so as to meet the actual power demand of the equipment.

- Lithium batteries connected in series

Add the voltage of batteries, capacity remains the same, and internal resistance increases. - Lithium batteries connected in paralle

Constant voltage, added capacity, reduced internal resistance, and extended power supply time. - Lithium batteries connected in series and parallel

3.7V single battery can be assembled into battery pack with a voltage of 3.7*(N)V as required (N: number of single batteries)

For example, 7.4V, 12V, 24V, 36V, 48V, 60V, 72V, etc. - Capacity of Parallel Connection

2000mAh single battery can be assembled into a battery pack with capacity of 2*(N)Ah as required (N: number of single batteries)

For example, 4000mAh, 6000mAh, 8000mAh,5Ah, 10Ah, 20Ah, 30Ah, 50Ah, 100Ah, etc.

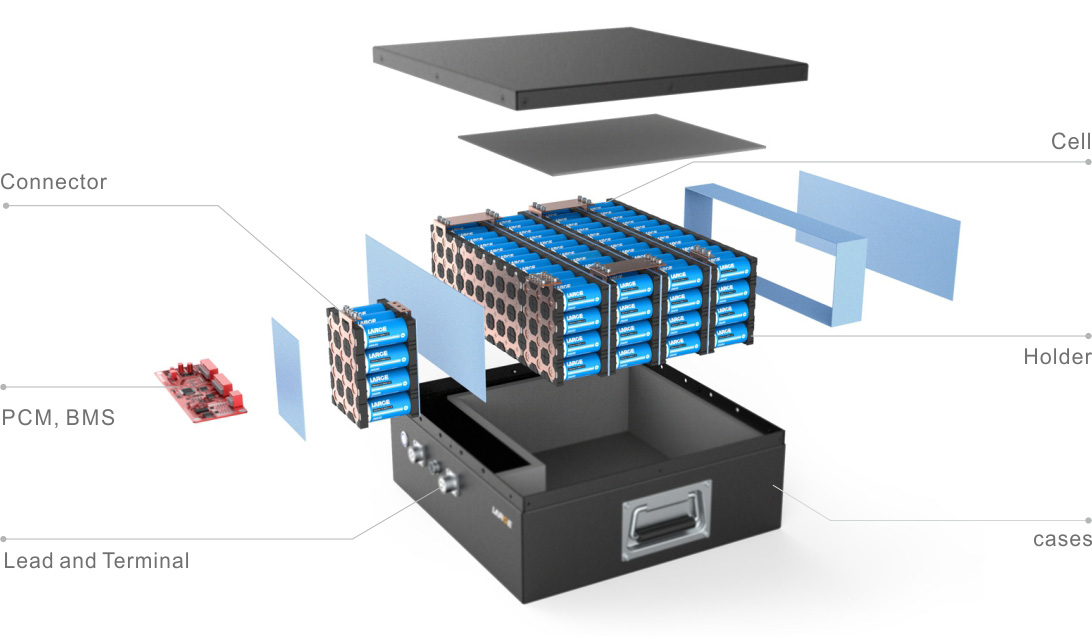

Lithium Battery Pack

Lithium battery pack technique refers to the processing, assembly and packaging of lithium battery pack. The process of assembling lithium cells together is called PACK, which can be a single battery or a lithium battery pack connected in series or parallel. The lithium battery pack usually consists of a plastic case, PCM, cell, output electrode, bonding sheet, and other insulating tape, double-coating tape, etc.

- Lithium cell: The core of a finished battery

- PCM: Protection functions of over charge, over discharge, over current, short circuit, NTC intelligent temperature control.

- Plastic case: the supporting skeleton of the entire battery; Position and fix the PCM; Carry all other non-case parts and limit.

- Terminal lead: It can provide a variety of terminal wire charging and discharging interface for a variety of electronic products, energy storage products and backup power.

- Nickel sheet/bracket: Connection and fixing component of the cell

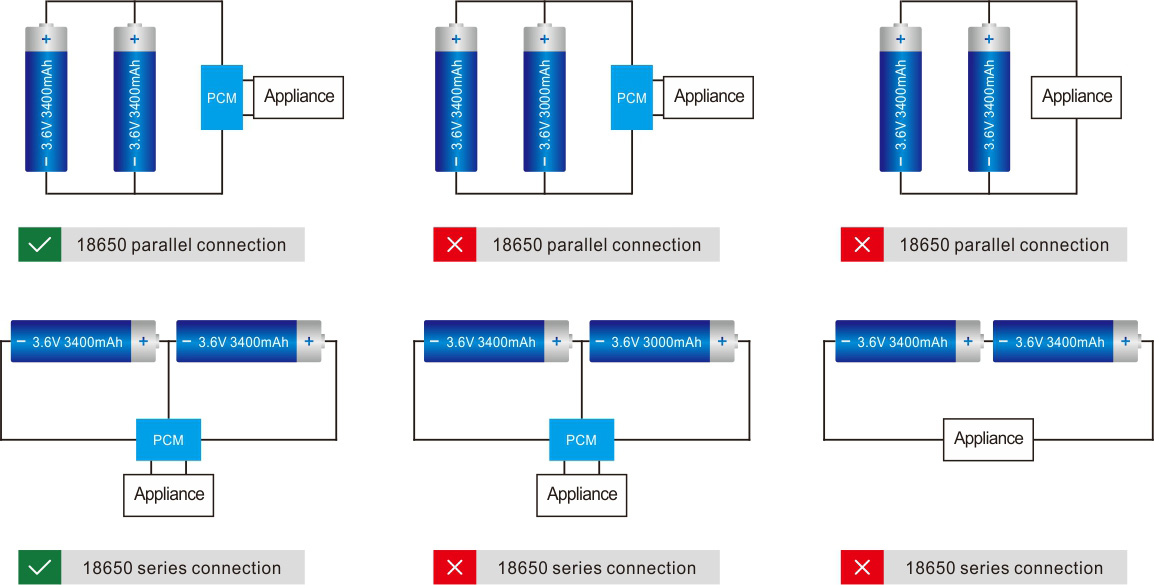

Lithium Battery Series and Parallel Connection

Due to security reasons, lithium ion batteries need an external PCM used for battery monitoring for each battery. It is not recommended to use batteries in parallel. If connect in parallel, make sure the consistency of the battery parameters (capacity, internal resistance, etc.), the other batteries in series need to have consistent parameters, otherwise, the performance of the battery pack can be much worse than the performance of a single cell.

Lithium battery matching criteria

voltage difference ≤ 10 mv, impedance difference ≤ 5 mΩ, capacity difference ≤20mA

The purpose of lithium battery matching is to ensure that every cell in the battery has consistent capacity, voltage and internal impedance, because inconsistent performances will make lithium battery have various parameters during using. Voltage imbalance will happen. After a long run, the battery will overcharge, over discharge, capacity lost, or even fire to explode.

1.Series and Parallel Connection Mode of Lithium Battery

Two Lithium Batteries Connected in Series (7.4V Lithium Battery)

| model | 18650-2S1P | 18650-2S1P | 18650-2S2P | 18650-2S3P |

| Voltage | 7.4V | 7.4V | 7.4V | 7.4V |

| Capacity | 2200/2500/3000mAh | 2200/2500/3000mAh | 6000mAh | 9000mAh |

| Dimension | 18*105mm | 18*36*65mm | 37*37*66mm | 37*55*66mm |

| Weight | 90g | 90g | 180g | 270g |

Three Lithium Batteries Connected in Series (11.1V Lithium Battery)

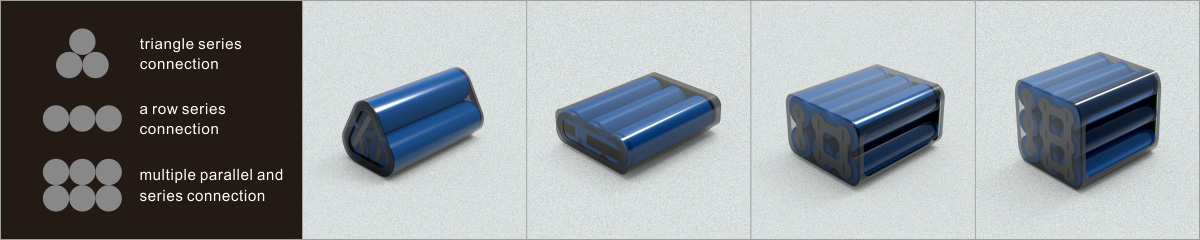

| Series and Parallel Connection Mode | 18650-3S1 P triangle | 18650-3S1P in-line | 18650-3S2P | 18650-3S3P |

| Voltage | 11.1V | 11.1V | 11.1V | 11.1V |

| Capacity | 2200/2500/3000mAh | 2200/2500/3000mAh | 6000mAh | 9000mAh |

| Dimension | 66.5*36.6*36.6mm | 69.8*55.7*18.8mm | 66.8*55.0*40.8mm | 60.6*68.0*56.1mm |

| Weight | 155g | 158g | 285g | 425g |

Four Lithium Batteries Connected in Series (14.8V Lithium Battery)

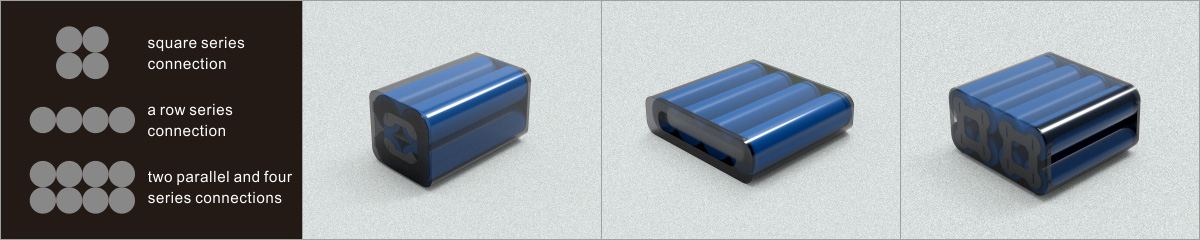

| Series and Parallel Connection Mode | 18650-4S1P square | 18650-4S1P In-line | 18650-4S2P |

| Voltage | 14.8V | 14.8V | 14.8V |

| Capacity | 2200/2500/3000mAh | 2200/2500/3000mAh | 6000mAh |

| Dimension | 69.6*37.7*37.7mm | 69.3*73.4*17.6mm | 70.6*74.2*37.1mm |

| Weight | 181g | 191g | 371g |

Six Lithium Batteries Connected in Series (22.2V Lithium Battery)

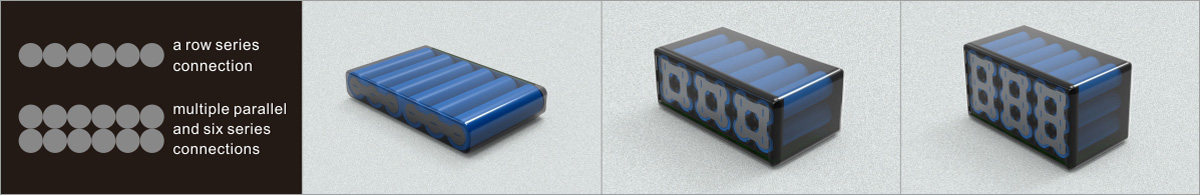

| Series and Parallel Connection Mode | 18650-6S1P In-line | 18650-6S2P | 18650-6S3P |

| Voltage | 25.2V | 25.2V | 25.2V |

| Capacity | 2000/3000mAh | 6000mAh | 9000mAh |

| Dimension | 114*72*22mm | 114*72*41mm | 114*72*60mm |

| Weight | 303g | 570g | 835g |

2.Lithium Battery Wire/Terminal

The length of the plug and lead of the lithium battery pack can be customized according to the customer’s electrical equipment.

3.Calculation Lithium Battery Connected in Series and Parallel

We all know that lithium battery voltage increases after series connection, capacity increases after parallel connection, then how to calculate a lithium battery quantity of series or parallel connection, and how many cells?

Before the calculation, we need to know which cell specification of the battery pack is adopted for the assembly, because different cells have different voltage and capacity. The cell quantity of series and parallel connection required to assemble a specific lithium battery pack varies. The common lithium cell types on the market are: 3.7V LiCoO2, 3.6V ternary, 3.2V LFePO4, 2.4V lithium titanate. The capacity is different because of the cell size, material and manufacturers.

Take 48V 20Ah Lithium Battery Pack for Example

- Suppose the size of the single cell used is 18650 3.7V 2000mAh

- Cell quantity of series connection: 48V/3.7V=12.97. That is 13 cells in series.

- Cell quantity of parallel connection: 20Ah/2Ah=10. That is 10 cells in parallel.

Commonly Used Lithium Battery Connected in series

| Nominal Voltage | Battery Category | Common Quantity of series connection | Charging Voltage |

| 12V | 3.7V LiCoO2 | 3S | 12.6V |

| 3.2V LiFePO4 | 4S | 14.6V | |

| 24V | 3.7V LiCoO2 | 7S | 29.4V |

| 3.2V LiFePO4 | 8S | 29.2V | |

| 36V | 3.7V LiCoO2 | 10S | 42.0V |

| 3.7V LiCoO2 | 11S | 46.2V | |

| 3.2V LiFePO4 | 11S | 40.2V | |

| 3.2V LiFePO4 | 12S | 43.8V | |

| 48V | 3.7V LiCoO2 | 13S | 54.6V |

| 3.7V LiCoO2 | 14S | 58.8V | |

| 3.2V LiFePO4 | 15S | 58.8V | |

| 3.2V LiFePO4 | 16S | 58.8V | |

| 60V | 3.7V LiCoO2 | 17S | 71.4V |

| 3.2V LiFePO4 | 20S | 73.0V | |

| 72V | 3.7V LiCoO2 | 20S | 84.0V |

| 3.2V LiFePO4 | 24S | 87.6V |

Lithium Battery Assembly Process

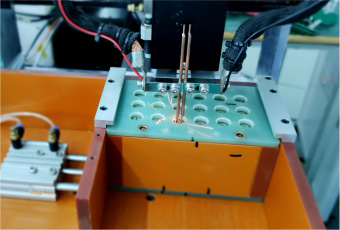

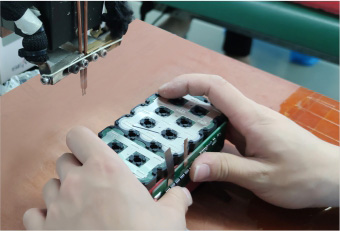

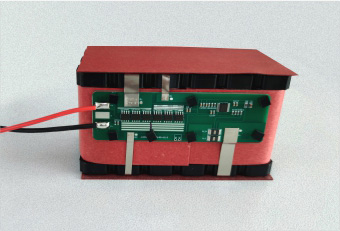

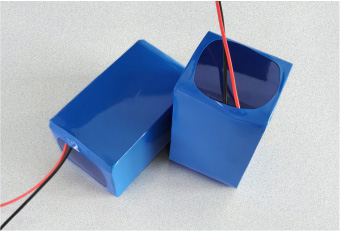

18650-3S6P/11.1V/15600mAh Lithium Battery Assembly Process

-

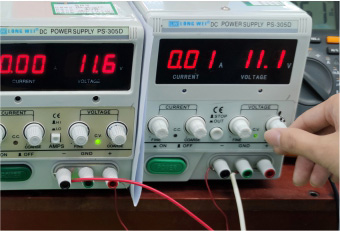

Cell Capacity Grading

Capacity Difference≤30mAh

After capacity grading, stay still for 48-72h and then distribute. -

Voltage Internal Impedance Sorting and Matching

Voltage Difference≤5mV

Internal Impedance Difference≤5mΩ 8 cells with similar voltage internal impedance are distributed together. -

Cell Spot Welding

The use of formed nickel strip eliminates the problems of spurious joint, short circuit, low efficiency and uneven current distribution

-

Welded PCM

Make sure that the circuit board has no leakage components, and the components have no defective welding.

-

Battery Insulation

Paste the fibre, silicone polyester tape for insulation.

-

Battery Pack Aging

For the quality of the battery, improve the stability, safety and service life of the lithium battery.

-

PVC Shrink Film

Position the two ends after heat shrinking,

then heat shrink the middle part.

Put PVC film in the middle. No whiten after stretching. No hole. -

Finished Product Performance Test

Voltage:10.8~11.7V

Internal Impedance:≤150mΩ

Charge-discharge and overcurrent performance test. -

Battery Code-spurting

Code-spurting cannot be skewed, and it needs legible handwriting

Precautions for Lithium Batteries in Series and Parallel

- Don’t use batteries with different brands together.

- Do not use batteries with different voltages together.

- Do not use different capacities or old and new lithium batteries together.

- Batteries with different chemical materials cannot be used together, such as nickel metal hydride and lithium batteries.

- Replace all batteries when electricity is scarce.

- Use the lithium battery PCM with corresponding parameters.

- Choose batteries with consistent performance. Generally, distributing of lithium battery cells is required for series and parallel connection. Matching standards: voltage difference≤10mV, impedance difference ≤5mΩ, capacity difference ≤20mA

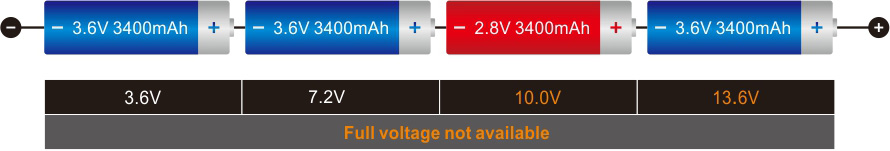

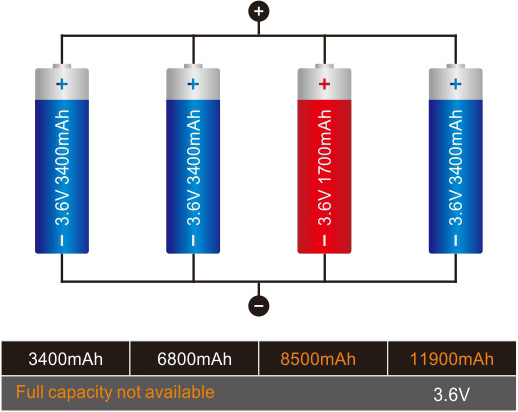

1.Lithium Battery With Different Voltage Connected in Series

Due to the consistency issue of lithium batteries, when the same system (such as ternary or lithium iron) is used for series or parallel connection, it is also necessary to select the batteries with the same voltage, internal impedance and capacity for matching. Batteries with different voltage platforms and different internal impedance used in series will cause a certain battery to be fully charged and discharged first in each cycle. If there is a PCM and no fault occurs, the capacity of the whole battery will be reduced. If there is no PCM, the battery will be overcharged or over discharged, which will damage the battery.

2.Lithium Batteries With Different Capacities Connected in Parallel

If different capacities or old and new lithium batteries are used together, there may be leakage, zero voltage and other issues, because during the charging process, capacity differences make some batteries overcharge, some batteries not, while during discharge process, high capacity batteries do not run out of power, but low capacity batteries over discharge. In such a vicious cycle, the batteries will be damaged by leakage or low (zero) voltage.

To assemble lithium batteries, connect them in parallel or in series first?

-

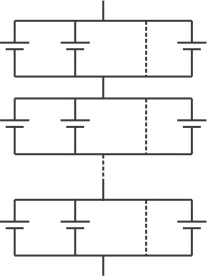

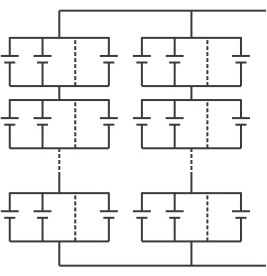

Topological Structure of Lithium Battery Connected in Series and Parallel

The typical connection modes of a lithium battery pack are connecting first in parallel and then in series, first in series and then in parallel, and finally, mixing together.

Lithium battery pack for pure electric buses is usually connected first in parallel and then in series.

Lithium battery pack for power grid energy storage is tend to be connected first in series and then in parallel.

- Advantages of Lithium Batteries First Connected in Parallel and Then in Series

If a lithium battery cell automatically exits, except the capacity reduction, it does not affect parallel connection;

In parallel connection, a short circuit of a lithium battery cell may cause short circuit due to large current, which is usually avoided by using fuse protection technology. - Disadvantages of Lithium Batteries First Connected in Parallel and Then in Series

If a lithium battery cell automatically exits, except the capacity reduction, it does not affect parallel connection;

In parallel connection, a short circuit of a lithium battery cell may cause short circuit due to large current, which is usually avoided by using fuse protection technology. - Advantages of Lithium Batteries First Connected in Series and Then in Parallel

First connecting the batteries in series according to the capacity, for example, 1/3 of the whole battery capacity are connected in series, and then connecting the rest in parallel, will reduce the failure probability of high-capacity lithium battery modules. First series and then parallel connection help the consistency of the lithium battery pack. - From the perspective of the reliability of the lithium battery connection, the development trend of voltage inconsistency and the influence of performance, the connection mode of first parallel and then series is better than that of first series and then parallel, and the topology structure of first series and then parallel lithium battery is conducive to the detection and management of each lithium battery cell in the system.

Lithium Batteries Charging in Series and Parallel

1.Charging Lithium Batteries In Series

At present, lithium battery tends to be charged in series, which is mainly due to its simple structure, low cost and easy realization. But as a result of different capacity, internal impedance, aging characteristics and self-discharge performance, when charge lithium battery in series, battery cell with the smallest capacity will be fully charged first, and at this point, the other battery cell is not full of electricity. If continue to charge in series, the fully charged battery cell may be overcharge.

Lithium Battery overcharge will damage the battery performance, and even lead to explosion and injuries, therefore, to prevent battery cell overcharging, lithium battery has equipped with Battery Management System (BMS). The Battery Management System has overcharge protection for every single lithium battery cell, etc. When charging in series, if the voltage of a single lithium battery cell reaches the overcharge protection voltage, the battery management system will cut off the whole series charging circuit and stop charging to prevent the single lithium battery cell from being overcharged, which will cause other lithium batteries unable to be fully charged.

2.Charging Lithium Batteries In Parallel

In parallel charging of lithium batteries, each lithium ion battery needs equalizing charge, otherwise, the performance and life of the whole lithium ion battery pack will be affected. Common charging equalization technologies include: constant shunt resistance equalizing charge, on-off shunt resistance equalizing charge, average battery voltage equalizing charge, switch capacitor equalizing charge, step-down converter equalizing charge, inductance equalizing charge, etc.

Several problems need to be paid attention to in parallel charging of lithium batteries:

- Lithium batteries with and without PCM cannot be charged in parallel. Batteries without PCM can easily be damaged by overcharging.

- Batteries charged in parallel usually need to remove the built-in PCM of the battery and use a unified battery PCM.

- If there is no PCM in parallel charging battery, the charging voltage must be limited to 4.2V and 5V charger cannot be used.

After lithium ion batteries connecting in parallel, there will be a charging protection chip for lithium battery charging protection. Lithium battery manufacturers have fully considered the change characteristics of lithium battery in parallel before battery production. The above requirement of current design and choice of batteries are very important, so that users need to follow the instructions of parallel lithium batteries charging step by step, so as to avoid the possible damage for incorrect charge.

3.Notes for Lithium Battery Charging

- Special charger must be used for lithium battery, or battery may not reach saturation state, affecting its performance.

- Before charging the lithium battery, it does not need to discharge completely.

- Do not keep the charger on the socket for a long time. Remove the charger as soon as the battery fully charged.

- Batteries shall be taken out of electric appliances that have not been used for a long time and stored after they are fully discharged.

- Do not plug the anode and cathode of the battery into the opposite direction, otherwise, the battery will swell or burst.

- Nickel charger and lithium charger cannot be used together.