Why Are LiFePO4 Batteries So Expensive? Unpacking the Cost Factors

LiFePO4 (Lithium Iron Phosphate) batteries are renowned for their reliability, safety, and long lifespan, which make them a preferred choice for a wide range of applications from electric vehicles to solar energy systems. However, their price point is often higher than other types of batteries, leading many to wonder why these batteries come with a higher cost. This article explores the various factors that contribute to the cost of LiFePO4 batteries and how Himax Electronics is working to provide cost-effective solutions without compromising on quality.

Understanding LiFePO4 Batteries

LiFePO4 batteries offer several advantages over traditional lithium-ion batteries, including:

- Longer Lifespan: They can last for more than 2000 charge cycles while maintaining high performance.

- Improved Safety: LiFePO4 chemistry is more stable and safer, reducing the risk of thermal runaway and fires.

- Better Temperature Tolerance: These batteries perform well under a wide range of temperatures.

- Eco-Friendly: They are less toxic and more environmentally friendly than other lithium batteries.

Factors Contributing to the High Cost of LiFePO4 Batteries

- Material and Production Costs:

- Cathode Material: The cathode material in LiFePO4 batteries, lithium iron phosphate, involves costly processing and synthesis techniques which contribute to higher production costs.

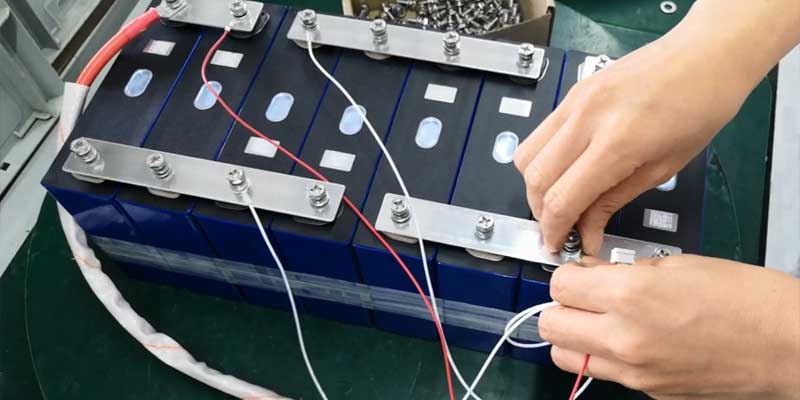

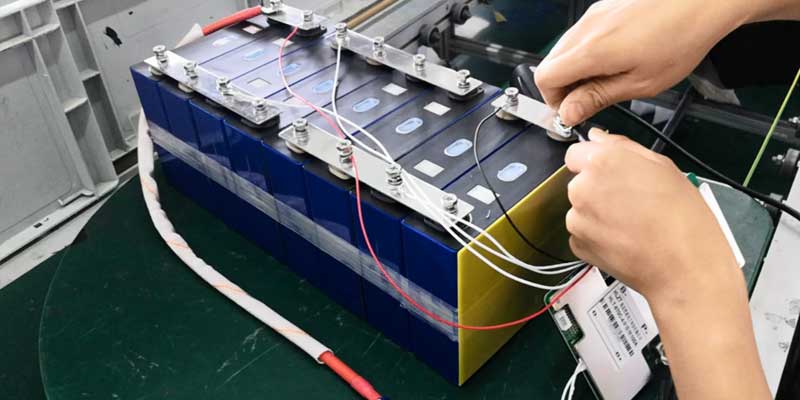

- Manufacturing Complexity: The process to safely and effectively produce these batteries is more complex and stringent than that of standard lithium-ion batteries.

- Research and Development:

- Innovative Technology: Significant investment in research and development is required to enhance the performance and safety features of LiFePO4 batteries.

- Patent Costs: The costs associated with obtaining and maintaining patents for new technologies also add to the expense.

- Economies of Scale:

- Smaller Production Scale: Compared to other types of batteries, LiFePO4 batteries are produced in smaller quantities, which does not allow for the same economies of scale.

- Market Demand: While growing, the demand for LiFePO4 batteries has not yet reached the level of more traditional lithium-ion batteries, which affects production costs.

- Quality and Certification:

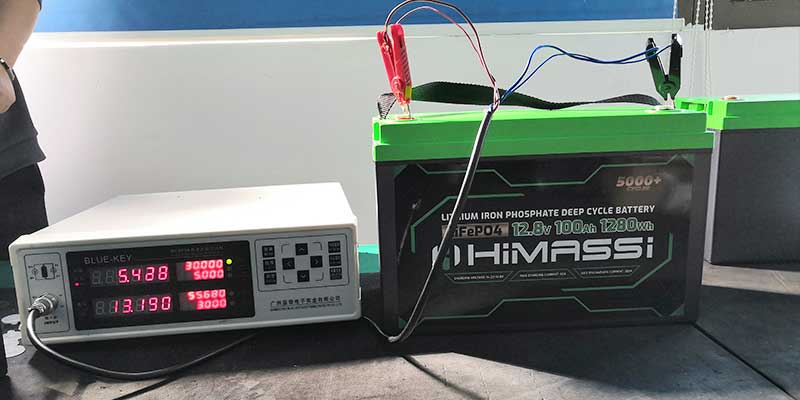

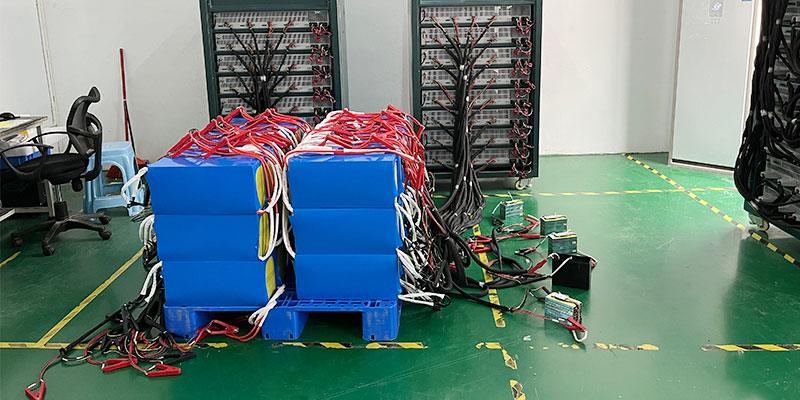

- Stringent Standards: LiFePO4 battery must meet rigorous safety and quality standards, requiring advanced testing and quality control, which increases production costs.

- Certifications: Obtaining industry certifications for safety, performance, and environmental compliance can be costly.

- Advanced Battery Management Systems (BMS):

- Complex BMS: LiFePO4 batteries typically require more sophisticated battery management systems to ensure performance and longevity, adding to their cost.

How Himax Electronics Enhances Value

Himax Electronics is dedicated to making LiFePO4 battery technology more accessible and affordable through several initiatives:

- Innovative Manufacturing Processes: Himax invests in cutting-edge manufacturing technologies that reduce waste and increase efficiency, lowering production costs.

- Bulk Procurement Strategies: By leveraging bulk procurement for materials, Himax can reduce the cost per unit, savings that are passed on to the customers.

- Recycling Programs: Himax supports and invests in recycling programs which help in reducing the need for raw materials, thereby diminishing the overall production costs and environmental impact.

- Customer-Centric Solutions: Himax provides customized solutions that ensure customers receive the most cost-effective battery configurations for their specific needs, maximizing their investment.

Conclusion

While the upfront cost of LiFePO4 batteries may be higher than other types, their long-term value, superior safety, performance, and environmental benefits justify the investment. Himax Electronics is at the forefront of reducing these costs while enhancing the performance and accessibility of LiFePO4 battery technology. By choosing Himax, customers benefit not only from high-quality products but also from the company’s commitment to sustainable and affordable energy solutions.

For more information on batteries or to explore cost-effective solutions from Himax Electronics, visit their website or contact their support team.