In the realm of battery technologies, safety is paramount. Among the various types available today, LiFePO4 (Lithium Iron Phosphate) batteries are frequently discussed not only for their performance and efficiency but also for their safety characteristics. As consumers and industries alike increasingly turn to these batteries, questions about their safety, particularly regarding fire risks, often arise. This article delves into whether LiFePO4 batteries can catch fire, under what circumstances, and how using products from Himax Electronics can mitigate these concerns.

Introduction to LiFePO4 Batteries

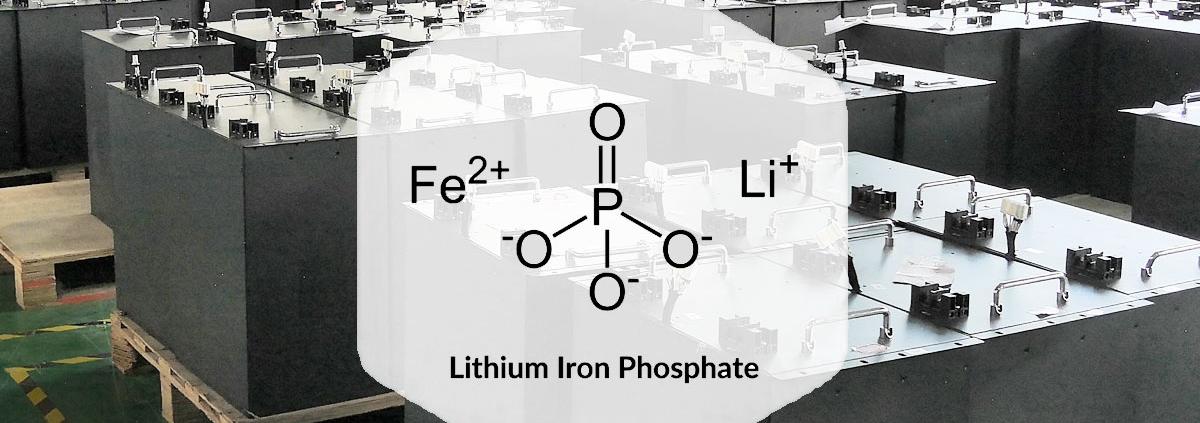

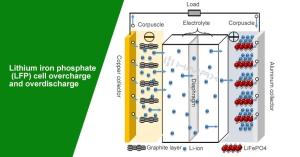

LiFePO4 batteries are a type of lithium-ion battery known for their robust safety profile and longevity. They are constructed from lithium iron phosphate, which serves as the cathode material, paired typically with a graphite anode. This combination offers unique advantages in terms of thermal and chemical stability, which directly influences their safety.

Chemical and Thermal Properties of LiFePO4 Batteries

The chemical makeup of LiFePO4 batteries provides significant safety benefits:

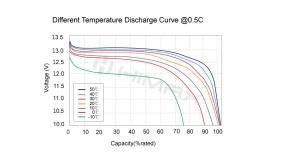

• Thermal Stability: LiFePO4 batteries are capable of withstanding high temperatures without degrading. This characteristic is crucial because many battery fires and explosions in other types of lithium batteries occur after thermal runaway, a condition where an increase in temperature leads to a self-sustaining exothermic reaction.

• Chemical Stability: The phosphate-based cathode material does not react violently if the battery is damaged, which is a common issue with other lithium-ion batteries that use metal oxides.

Comparative Safety Analysis

When compared with other lithium-ion batteries, LiFePO4 batteries exhibit:

• Lower Risk of Thermal Runaway: Thanks to their phosphate chemistry, LiFePO4 batteries have a much higher thermal runaway threshold than other lithium-ion batteries.

• Enhanced Safety in Case of Breach: Even when physically damaged, LiFePO4 batteries are less likely to catch fire or explode, thanks to the stability of their chemical components.

Risk Factors and Safety Considerations

While LiFePO4 batteries are generally safer, they are not entirely devoid of risks. Key factors that could potentially lead to safety issues include:

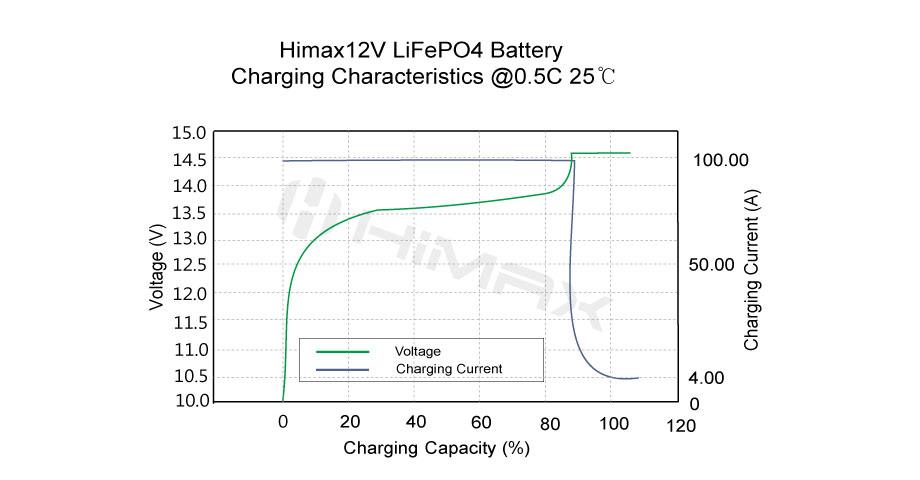

• Improper Charging Practices: Using a non-compatible charger or exceeding the recommended charging limits can lead to problems, including overheating.

• Mechanical Damage: Severe impacts or punctures can compromise the integrity of the battery, leading to short circuits.

• Environmental Factors: Exposing batteries to extreme environmental conditions, such as very high temperatures or moisture, can reduce safety.

Best Practices for Maintaining Safety

To ensure the safety of LiFePO4 batteries:

1 Use Appropriate Chargers: Always use a charger specified for LiFePO4 batteries to prevent overcharging.

2 Regular Inspections: Check the batteries regularly for signs of damage or wear and replace them if necessary.

3 Adhere to Manufacturer’s Guidelines: Follow the installation and maintenance instructions provided by the manufacturer to optimize battery performance and safety.

LiFePO4 Batteries in Application

Several practical applications of LiFePO4 batteries highlight their safety benefits:

• Electric Vehicles (EVs): LiFePO4 batteries are favored in EVs due to their lower risk of catching fire, even in accidents.

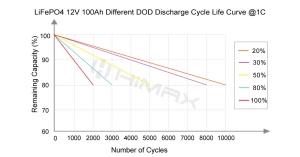

• Renewable Energy Storage: Their stability makes them ideal for storing solar or wind energy, as they can handle the cyclic demands of these systems without significant degradation or risk.

Himax Electronics: A Commitment to Quality and Safety

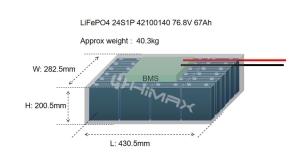

At Himax Electronics, we prioritize the safety and reliability of our LiFePO4 batteries. Our products are designed with integrated safety mechanisms that prevent overcharging and overheating. Additionally, we offer:

• Advanced Battery Management Systems (BMS): Our BMS technology enhances safety by continuously monitoring battery status and adjusting charging parameters as needed.

• Customized Solutions: We understand that each application has unique demands, and we cater to these needs with tailor-made battery solutions.

• Expert Support: Our team of experts is always ready to assist with any questions or concerns, ensuring that you can use our batteries with confidence.

Conclusion

LiFePO4 batteries stand out in the battery market for their exceptional safety profile, making them an ideal choice for applications where safety cannot be compromised. By choosing Himax Electronics for your LiFePO4 battery needs, you benefit from our commitment to quality, customized solutions, and comprehensive customer support. Trust us to power your applications safely and efficiently. For more information, please visit our website or contact our customer service team.