With the development of custom lithium battery pack , the cause of lithium polymer battery bulge has many reasons. According to experimental research and development experience, researchers has concluded 3 major reasons :

- . During battery cycling, the battery electrode expansion caused the battery thickness increased.

- . Due to the gas production from electrolyte oxidation and decomposition cause battery bulge.

- . Bulging caused by production process defects, such as sealing of the battery not tight enough cause the introduced moisture and damaged corners.

At the different custom lithium battery pack systems, the main reason of battery thickness change is different, such as the negative system of LTO battery, the bulge main reason is gas bulge; at graphite negative system, the thickness of the electrode and production of the gas all have a promoting effect.

-

Electrode thickness change

During charge battery pack cell thickness increase is mainly attribute to the expansion of negative, positive bulge rate is only 2% to 4%, negative electrode normally assemble by composition of graphite, adhesive, and conductive carbon, among them graphite itself bulge rate reached 10%, the reason that cause of graphite electrode bulge are mainly included : SEI film formation, State of Charge, Production process parameters and other influencing factors.

(1) SEI film formation; During the first charging and discharging process of li ion customized battery packs, the electrolyte undergoes a reduction reaction at the solid-liquid phase interface of the graphite particles, forming a passivation layer (SEI film) covering the surface of the electrode material. The generation of the SEI film cause the thickness of the anode is significantly increased, and the thickness of the cell is increased by about 4% due to the formation of the SEI film. From the perspective of the long-term cycle process, according to the physical structure and specific surface of different graphites, the dissolution of SEI and the dynamic process of new SEI production will occur during the cycle process. For example, flake graphite has a greater expansion rate than spherical graphite.

(2) State of charge; During the cycle of the custom lithium battery pack cell, the volume expansion of the graphite anode has a good periodic function relationship with the SOC of the cell, that is, with the continuous insertion of lithium ions in the graphite (the increase of the SOC of the cell) the volume Gradually expand, when li ion customized battery packs are released from the graphite anode, the SOC of the cell gradually decreases, and the volume of the corresponding graphite anode gradually shrinks.

(3) Process parameters; From the perspective of process parameters, the compaction density has a great influence on the graphite anode. During the cold pressing process of the pole piece, a large compressive stress is generated in the graphite anode film layer, and this stress is baked at high temperature in the subsequent pole piece. It is difficult to completely release the waiting process. When the battery cell is being charged and discharged cyclically, due to the joint action of multiple factors such as the insertion and extraction of lithium ions, and the swelling of the electrolyte on the adhesive, the diaphragm stress is released during the cycle and the expansion rate increases. On the other hand, the size of the compaction density determines the void capacity of the anode film layer. The large pore capacity in the film layer can effectively absorb the expanded volume of the pole piece. The small void capacity means that when the pole piece expands, there is not enough space to absorb the expansion. The generated volume, at this time, can only expand to the outside of the film layer, which is manifested as the volume expansion of the anode sheet.

(4) Other factors The bonding strength of the adhesive (adhesive strength of the adhesive, graphite particles, conductive carbon and the interface between the current collectors), charge and discharge rate, swelling of the adhesive and electrolyte, graphite particles The shape and bulk density of the anode, as well as the increase in the volume of the electrode piece caused by the failure of the adhesive during the cycle, all have a certain degree of influence on the expansion of the anode.

-

Expansion rate calculation:

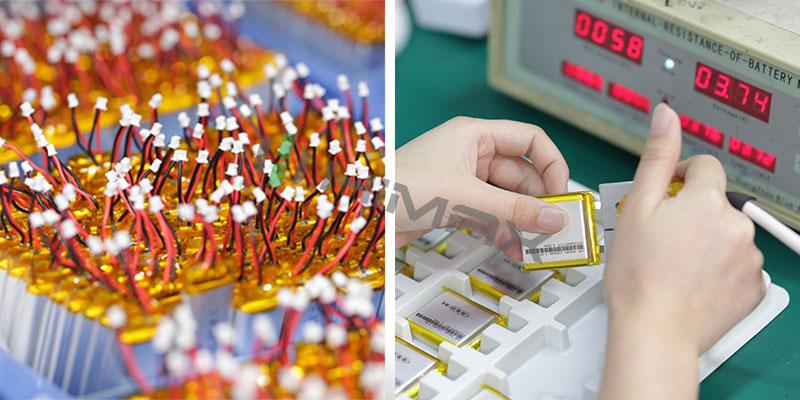

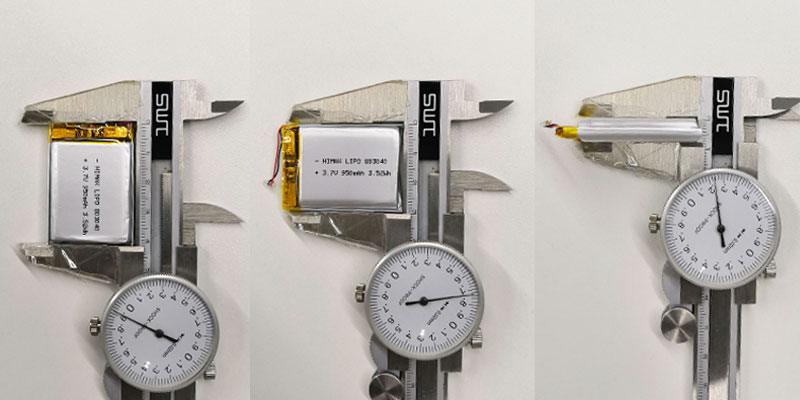

The calculation of the expansion rate uses the quadratic element to measure the dimensions of the anode sheet in the X and Y directions, and the micrometer to measure the thickness in the Z direction. They are measured after the sheet is punched and the battery is fully charged.

-

Effect of compaction density and coating quality on negative electrode expansion

Taking compaction density and coating quality as factors, three different levels were selected for each, and a full factorial orthogonal experimental design was carried out (as shown in Table 1), and the other conditions of each group were the same.

It can be seen from Figure 2(a) and (b) that after the cell is fully charged, the expansion rate of the anode sheet in the X/Y/Z direction increases with the increase of the compaction density. When the compacted density increases from 1.5g/cm3 to 1.7g/cm3, the expansion rate in the X/Y direction increases from 0.7% to 1.3%, and the expansion rate in the Z direction increases from 13% to 18%. It can be seen from Figure 2(a) that under different compaction densities, the expansion rate in the X direction is greater than that in the Y direction. The reason for this phenomenon is mainly caused by the cold pressing process of the pole piece. When rolling, according to the law of least resistance, when the material is subjected to external force, the material particles will flow along the direction of least resistance.

When the anode sheet is cold-pressed, the direction with the least resistance is the MD direction (the Y direction of the pole piece, as shown in Figure 3). The stress is easier to release in the MD direction, while the TD direction (the X direction of the pole piece) has greater resistance, and the roller The stress is not easy to release during the compression process, and the stress in the TD direction is larger than that in the MD direction. Therefore, after the electrode sheet is fully charged, the expansion rate in the X direction is greater than the expansion rate in the Y direction. On the other hand, the compaction density increases and the pore capacity of the electrode sheet decreases (as shown in Figure 4). When charging, there is no There is enough space to absorb the expanded volume of graphite, and the external manifestation is that the entire pole piece expands in the three directions of X, Y, and Z. It can be seen from Figure 2(c) and (d) that the coating mass increases from 0.140g/1,540.25mm2 to 0.190g/1,540.25mm2, and the expansion rate in the X direction increases from 0.84% to 1.15%, Y The directional expansion rate increased from 0.89% to 1.05%, and the Z-direction expansion rate trend was opposite to the X/Y direction change trend, showing a downward trend, decreasing from 16.02% to 13.77%. It shows that the expansion of graphite anode presents one after another in the three directions of X, Y and Z, and the change of coating quality is mainly reflected in the significant change of film thickness. The above anode change rule is consistent with the literature results, that is, the smaller the ratio of the current collector thickness to the film thickness, the greater the stress in the current collector.

-

Effect of Copper Foil Thickness on Negative Electrode Expansion

Two influencing factors are selected: copper foil thickness and coating quality. The copper foil thickness levels are 6 and 8 μm respectively. The anode coating qualities are 0.140g/1, 540.25mm2 and 0.190g/1, 540.25mm2 respectively. The compacted densities are all 1.6g/cm3, other experimental conditions in each group are the same, and the experimental results are shown in Figure 5. It can be seen from Figure 5(a) and (c) that under two different coating qualities, the expansion rate of the 8 μm copper foil anode sheet in the X/Y direction is less than 6 μm, indicating that the thickness of the copper foil increases due to the increase in its elastic modulus. (See Figure 6), that is, the resistance to deformation is enhanced, the constraint on the expansion of the anode is enhanced, and the expansion rate is reduced. According to the literature, under the same coating quality, when the thickness of the copper foil increases, the ratio of the current collector thickness to the film thickness increases, the stress in the current collector becomes smaller, and the expansion rate of the pole piece becomes smaller. In the Z direction, the change trend of the expansion rate is completely opposite. It can be seen from Figure 5(b) that as the thickness of the copper foil increases, the expansion rate increases. From the comparison of Figure 5(b) and (d), it can be seen that when the coating quality When increasing from 0.140g/1 and 540.25mm2 to 0.190g/1 and 540.25mm2, the copper foil thickness increases and the expansion rate decreases. Although the increase in the thickness of the copper foil is beneficial to reducing its own stress (high strength), it will increase the stress in the film layer, resulting in an increase in the Z-direction expansion rate, as shown in Figure 5(b); as the coating quality increases, thick copper Although the foil promotes the increase in the stress of the film layer, it also enhances the restraint ability of the film layer. At this time, the restraint force is more obvious and the expansion rate in the Z direction decreases.

-

Effect of graphite type on negative electrode expansion

Five different types of graphite were used for experiments (see Table 2). The coating mass was 0.165g/1, 540.25mm2, the compaction density was 1.6g/cm3, and the copper foil thickness was 8μm. Other conditions were the same. The experimental results are shown in Figure 7 . As can be seen from Figure 7(a), the expansion rates of different graphites in the X/Y direction vary greatly, with a minimum expansion rate of 0.27% and a maximum of 1.14%. The Z-direction expansion rate has a minimum expansion rate of 15.44% and a maximum of 17.47%. , the expansion in the Z direction is small, consistent with the results analyzed in Section 2.2. Among them, the battery core using A-1 graphite showed serious deformation, with a deformation ratio of 20%. The other groups of battery cores did not show deformation, indicating that the X/Y expansion rate has a significant impact on the battery core deformation.

(1) When the compaction density is increased, the expansion rate of the anode sheet increases along the X/Y and Z directions during the full charging process, and the expansion rate in the X direction is greater than the expansion rate in the Y direction (the X direction is the cold pole plate The direction of the roller axis during the pressing process, and the Y direction is the direction of the machine belt).

(2) When the coating quality is increased, the expansion rate in the X/Y direction increases, and the expansion rate in the Z direction decreases; increasing the coating quality will lead to an increase in the tensile stress in the current collector.

(3) Improving the strength of the current collector can suppress the expansion of the anode sheet in the X/Y direction.

(4) Different types of graphite have large differences in expansion rates in the X/Y and Z directions, and the expansion in the X/Y direction has a greater impact on the deformation of the battery.

-

Bulging caused by battery gas

The internal gas production of the custom lithium battery pack is another important cause of battery bulging. Whether the custom lithium battery Pack is cycled at normal temperature, cycled at high temperature, or left at high temperature, it will produce gas bulging to varying degrees. During the first charge and discharge process of the battery, an SEI (Solid Electrolyte Interface) film will be formed on the surface of the electrode. The formation of the negative SEI film mainly comes from the reduction and decomposition of EC (Ethylene Carbonate). While alkyl lithium and Li2CO3 are generated, a large amount of CO and C2H4 will be generated. DMC (Dimethyl Carbonate) and EMC (Ethyl Methyl Carbonate) in the solvent will also form RLiCO3 and ROLi during the film formation process, accompanied by the production of CH4, C2H6, C3H8 and other gases and CO gas. In the PC (Propylene carbonate)-based electrolyte, relatively more gas is produced, mainly C3H8 gas generated by the reduction of PC. The lithium iron phosphate soft pack battery swells most severely after charging at 0.1C during the first cycle. It can be seen from the above that the formation of SEI will be accompanied by the generation of a large amount of gas, which is an inevitable process. The presence of H2O in impurities will destabilize the P-F bond in LiPF6 and generate HF. HF will cause instability in the battery system and produce gas. The presence of excess H2O will consume Li+ and generate LiOH, LiO2 and H2, resulting in gas generation. Gas will also be produced during storage and long-term charging and discharging. For sealed lithium-ion batteries, the occurrence of a large amount of gas will cause the battery to swell, thereby affecting the performance of the battery and shortening the service life of the battery. The main reasons why batteries produce gas during storage are as follows: (1) The H2O present in the battery system will cause the generation of HF, causing damage to the SEI. O2 in the system may cause oxidation of the electrolyte, resulting in the generation of a large amount of CO2; (2) If the SEI film formed for the first time is unstable, the SEI film will be destroyed during the storage stage, and the repair of the SEI film will release hydrocarbons. Class-based gases. During the long-term charge and discharge cycle of the battery, the crystal structure of the positive electrode material changes. Factors such as uneven point potential on the electrode surface cause the potential of some points to be too high. The stability of the electrolyte on the electrode surface decreases, and the electrode surface film continues to thicken. This increases the electrode interface resistance and further increases the reaction potential, causing the electrolyte to decompose on the electrode surface to produce gas, and the positive electrode material may also release gas.

In different systems, the degree of custom lithium battery pack bulging is different. In graphite anode system batteries, the main reasons for gas bulging are SEI film formation, excessive moisture in the cell, abnormal formation process, poor packaging, etc. As mentioned above, in the lithium titanate anode system, the industry generally believes that Li4Ti5O12 The swelling of batteries is mainly caused by the material itself easily absorbing water, but there is no definite evidence to prove this speculation. Xiong et al. from Tianjin Lishen Battery Company pointed out in the abstract of the paper of the 15th International Electrochemistry Conference that the gas components include CO2, CO, alkanes and a small amount of olefins, but no data support was given for their specific composition and proportion. Belharouak et al. used gas chromatography-mass spectrometry to characterize battery gas production. The main component of gas is H2, as well as CO2, CO, CH4, C2H6, C2H4, C3H8, C3H6, etc.

Gas composition of Li4Ti5O12/LiMn2O4 battery cycled at 30, 45, 60 ℃ for 5 months

The electrolyte system generally used in lithium-ion batteries is LiPF6/EC:EMC, where LiPF6 has the following balance in the electrolyte.

PF5 is a strong acid that easily causes the decomposition of carbonates, and the amount of PF5 increases with temperature. PF5 helps the electrolyte decompose to produce CO2, CO and CxHy gases. Calculations also show that the decomposition of EC produces CO and CO2 gases. C2H4 and C3H6 are generated by the redox reaction of C2H6 and C3H8 with Ti4+ respectively, while Ti4+ is reduced to Ti3+. According to relevant research, the generation of H2 comes from trace amounts of water in the electrolyte, but generally the water content in the electrolyte is about 20×10-6, which is harmful to the production of H2 gas. Wu Kai of Shanghai Jiao Tong University’s experiment chose graphite/NCM111 as a battery with very low contribution, and concluded that the source of H2 is the decomposition of carbonate under high voltage.

-

Abnormal processes lead to gas generation and expansion

Poor encapsulation, the proportion of flattened battery cells caused by poor encapsulation has been greatly reduced. We have already introduced the causes of poor sealing on the three sides of Top sealing, Side sealing and Degassing. Poor sealing on any side will cause battery cells. Most of them are Top sealing and Degassing. Top sealing is mainly caused by poor sealing of the Tab position, and Degassing is mainly caused by delamination. (Including the separation of PP and Al due to the influence of electrolyte and gel). Poor packaging causes moisture in the air to enter the battery core, causing the electrolyte to decompose and generate gas.

The surface of the Pocket is damaged, and the custom lithium battery pack core is abnormally damaged or artificially damaged during the flow-drawing process, resulting in damage to the Pocket (such as pinholes), allowing moisture to enter the interior of the battery core.

Corner damage, due to the special deformation of aluminum at the folded corners, the shaking of the air bag will distort the corners and cause Al damage (the larger the custom lithium battery pack core, the larger the air bag, the easier it is to be damaged), and lose the barrier effect on water. Wrinkle glue or hot melt glue can be added to the corners to alleviate the problem. In addition, it is forbidden to use air bags to move the battery cells during the various processes after top sealing. Pay more attention to the operation method to prevent the battery cells from swinging on the aging board.

The water content inside the battery cell exceeds the standard. Once the water content exceeds the standard, the electrolyte will fail and generate gas after formation or degassing. The main reasons for excessive water content inside the battery include: excessive water content in the electrolyte, excessive water content in the bare battery core after baking, and excessive humidity in the drying room. If it is suspected that excessive water content is causing flatulence, a retrospective inspection of the process can be carried out.

The formation process is abnormal, and the wrong formation process will cause the battery core to bloat.

The SEI film is unstable, and the battery cell’s emission function is slightly bloated during the charge and discharge process of the capacity test.

Overcharge and overdischarge, due to the abnormality of the process or machine or protection board, the battery core will be overcharged or over-discharged, and the battery core will be severely inflated.

Short circuit. Due to operational errors, the two tabs of the charged battery cell are in contact with each other and short circuit occurs. The custom lithium battery pack cell will inflate and the voltage will drop rapidly, and the tab will be burned black.

Internal short circuit, the short circuit of cathode and anode inside the battery core causes the battery core to discharge rapidly and heat up, and at the same time, it is severely gassed. There are many reasons for internal short circuit: design problems; isolation film shrinkage, curling, damage; Bi-cell misalignment; burrs piercing the isolation film; excessive clamp pressure; For example, due to insufficient width, the ironing machine excessively squeezed the battery body, resulting in short-circuiting of the cathode and anode, and flatulence.

Corrosion, the battery core corrodes, the aluminum layer is consumed by the reaction, loses its barrier effect on water, and flatulence occurs.

Vacuum pumping is abnormal, and the vacuum degree is abnormal due to system or machine reasons. Degassing is not thorough; the heat radiation area of Vacuum Sealing is too large, causing the degassing bayonet to be unable to effectively pierce the pocket bag, resulting in unclean vacuuming.

-

Measures to suppress abnormal gas production

Suppressing abnormal gas production needs to start from two aspects: material design and manufacturing process.

First of all, it is necessary to design and optimize the material and electrolyte system to ensure the formation of a dense and stable SEI film, improve the stability of the cathode material, and suppress the occurrence of abnormal gas production.

For the treatment of electrolyte, the method of adding a small amount of film-forming additives is often used to make the SEI film more uniform and dense, and to reduce the SEI film shedding during battery use and the custom lithium battery pack bulging caused by gas production during regeneration. Related studies have been reported and used in practice. For example, Cheng Su from Harbin University of Science and Technology reported that the use of film-forming additive VC can reduce battery bloating. However, most studies have focused on single-component additives, and the effect is limited. Cao Changhe and others from East China University of Science and Technology used VC and PS as a new type of electrolyte film-forming additive, and achieved good results. The gas production of the battery was significantly reduced during high-temperature storage and cycling. Studies have shown that the SEI film component formed by EC and VC is linear alkyl lithium carbonate, and the alkyl lithium carbonate attached to LiC is unstable at high temperature, and decomposes to generate gas (such as CO2, etc.) to cause battery swelling. The SEI film formed by PS is lithium alkyl sulfonate. Although the film has defects, it has a certain two-dimensional structure and is relatively stable when attached to LiC at high temperatures. When VC and PS are used in combination, PS forms a defective two-dimensional structure on the surface of the negative electrode when the voltage is low, and as the voltage increases, VC forms a linear structure of alkyl lithium carbonate on the surface of the negative electrode, and the alkyl lithium carbonate fills In the defects of the two-dimensional structure, an SEI film with a network structure stably attached to LiC is formed. The SEI membrane with this structure greatly improves its stability and can effectively suppress gas production caused by membrane decomposition.

In addition, due to the interaction between the positive electrode custom lithium battery Packcobalt oxide material and the electrolyte, the decomposition products will catalyze the decomposition of the solvent in the electrolyte. Therefore, surface coating of the positive electrode material can not only increase the structural stability of the material, but also reduce the interaction between the positive electrode and the electrolyte. The contact with the liquid reduces the gas generated by the catalytic decomposition of the active positive electrode. Therefore, forming a stable and complete coating layer on the surface of cathode material particles is also a major development direction at present.

If you have any question, please feel free to contact us:

- Name: Dawn Zeng (Director)

- E-mail address: sales@himaxelectronics.com

The most common drone safety issues, next to pilot error are related to battery failures. If you’ve ever experienced battery failure during charging, storage, or operation, then you understand how alarming and potentially dangerous it can be.

The most common drone safety issues, next to pilot error are related to battery failures. If you’ve ever experienced battery failure during charging, storage, or operation, then you understand how alarming and potentially dangerous it can be.