Parallel battery charging is a convenient way to increase your total battery capacity and extend runtime without boosting voltage. For users in homes, workshops, or construction sites — especially those working with LiPo packs or 12V systems — knowing how to safely use a parallel battery charger can prevent damage, swelling, or even fire risks. This guide walks you through the setup, safety checks, and real-world best practices backed by expert data and trusted authorities.

What Is a Parallel Battery Charger?

A parallel battery charger is designed to charge multiple batteries that are connected in parallel — meaning all positive terminals are joined together, and all negative terminals are joined together.

In this setup:

Voltage remains the same,

Capacity (Ah) adds up, increasing total runtime.

Parallel vs Series — Quick Comparison

Series connection: increases voltage (e.g., two 12V → 24V).

Parallel connection: increases capacity (two 12V 100Ah → still 12V, but 200Ah).

Use parallel charging when you need longer runtime at the same voltage, such as powering solar systems, tools, or drones.

When Should You Use Parallel Charging?

1. Home Backup or Solar Energy Systems

In off-grid solar setups, parallel charging keeps voltage stable while extending storage capacity — perfect for powering appliances longer.

2. Construction Sites and Power Tools

Builders and technicians often parallel-charge tool batteries to keep devices running continuously without downtime.

3. RC & Drone Enthusiasts

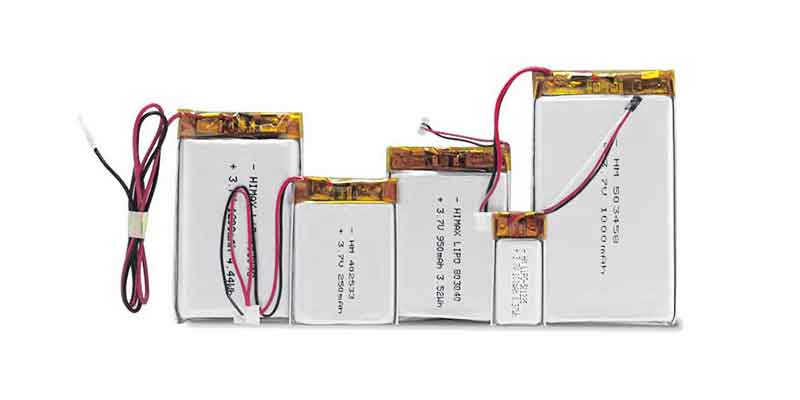

For LiPo packs, parallel charging saves time by charging multiple packs at once, provided they’re matched properly.

Always ensure batteries have the same voltage and similar capacity before parallel charging to avoid imbalance or internal short-circuiting.

Before You Start — Safety Checks & Preparation

Battery Matching Matters

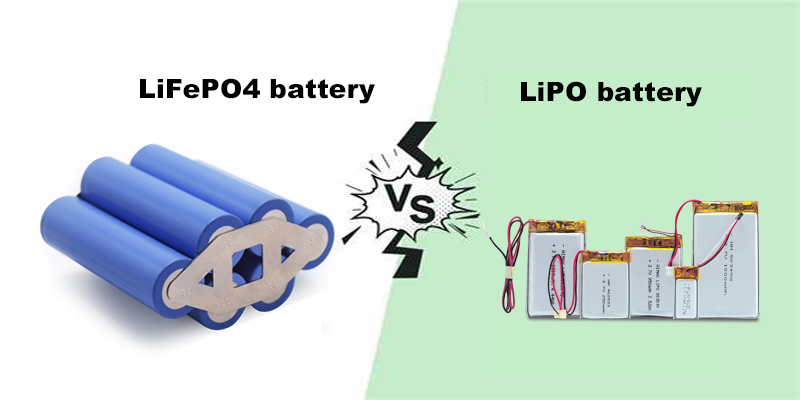

Only connect batteries that share the same voltage, chemistry, and age. Mixing old and new batteries or Li-ion and LiFePO4 cells can cause dangerous voltage imbalances.

Inspect for Damage or Swelling

If you see puffing or swelling — especially with LiPo batteries — do not charge them. Swollen batteries indicate gas buildup or internal breakdown. According to Battery University

, charging a swollen LiPo can lead to fire or explosion. Dispose of damaged cells immediately through certified e-waste centers.

Work Area Preparation

Charge in a well-ventilated, fire-resistant area. Avoid flammable materials nearby and use a LiPo safety bag for additional protection.

Equipment & Tools You Need

- A parallel-capable charger (multi-bank or smart LiPo charger).

- Balance leads or parallel boards for equal voltage distribution.

- Fuses or circuit breakers to prevent current surge.

- Correct cable gauge to handle the total current safely.

- LiPo safety bag or metal charging container.

Step-by-Step: How to Use a Parallel Battery Charger

Step 0 — Preparation

Wear insulated gloves and ensure your workspace is dry, non-conductive, and ventilated.

Step 1 — Match Batteries

All batteries must be the same voltage and state of charge (SoC). Measure with a voltmeter — the difference should not exceed 0.05V per cell for LiPo packs.

Step 2 — Connect Batteries in Parallel

Connect positive to positive, negative to negative using cables of equal length to balance resistance. Secure connections tightly.

Step 3 — Add Balancing Wires or Fuses

Use balance leads to equalize cell voltage between packs. Insert a fuse on each positive terminal to isolate a faulty battery if something goes wrong.

Step 4 — Connect the Charger

Attach the charger’s positive and negative leads to the parallel bank, not to each battery separately.

Using multiple chargers on the same parallel bank can cause current backflow and overheating — avoid this practice.

Step 5 — Set the Charger Parameters

Select correct chemistry: Li-ion, LiPo, AGM, or lead-acid.

Set voltage limit: typically 4.2V per cell for LiPo (follow manufacturer specs).

Set charge rate: around 1C or lower for longevity (e.g., 2A for a 2000mAh pack).

Step 6 — Monitor During Charging

Watch for abnormal heat, swelling, or odors. If temperature rises rapidly or a pack inflates, stop immediately and disconnect safely.

Step 7 — Finish & Store

When fully charged, disconnect the charger first, then the batteries. Store LiPo batteries at storage voltage (3.7–3.8V per cell) if not used for a while.

Special Notes for Swollen LiPo Users

Why LiPo Batteries Swell

Swelling is caused by gas buildup from overcharging, overheating, or internal damage. It’s an irreversible process indicating cell failure.

Never Charge or Compress a Swollen LiPo

Attempting to recharge or flatten a swollen battery can rupture the pouch and ignite flammable electrolytes. The U.S. Consumer Product Safety Commission (CPSC)

advises users to immediately stop use and dispose of such batteries properly.

Safe Disposal

Place the battery in a non-metallic container, cover terminals with tape, and take it to a local hazardous waste collection site. The National Fire Protection Association (NFPA) also provides detailed consumer safety guidelines for lithium-based products.

Common Mistakes & Troubleshooting

❌ Mixing batteries of different voltages or capacities.

❌ Charging each battery with a separate charger while connected in parallel.

❌ Ignoring balance leads — leading to uneven charging.

⚡ If charger shows error or overheat:

Disconnect all batteries.

Check fuse, wiring, and voltage.

Replace any pack with >0.05V deviation.

Best Practices Checklist

✅ Check all batteries for equal voltage and chemistry.

✅ Use fuses and equal-length cables.

✅ Avoid charging swollen or damaged cells.

✅ Charge in a fireproof area.

✅ Monitor constantly — never leave charging unattended.

Recommended Chargers & Accessories

When choosing a charger:

Look for parallel-capable smart chargers with auto-balance and overcurrent protection.

Ensure it supports your battery chemistry (LiPo, LiFePO4, AGM).

Choose trusted brands with UL or CE certifications and safety records.

FAQ

1. Can I charge two 12V batteries in parallel with two chargers?

Usually not. Using two chargers can cause uneven current flow and potential shorting. Use one properly rated charger for the entire parallel bank.

2. My LiPo battery is slightly swollen. Can I still charge it?

No. Even slight swelling means internal damage. Follow safe disposal steps from the CPSC lithium battery safety guide

3. How can I balance batteries when charging in parallel?

Use a parallel balance board or balance wires on your charger to equalize cell voltages. Always verify voltage uniformity before charging.