How to Charge a Li Ion Battery: Best Practices and Safety Tips

Lithium-ion (Li-ion) batteries are a cornerstone of modern portable electronics, powering everything from smartphones to laptops and electric vehicles. Known for their high energy density and long service life, these batteries require proper handling to ensure safety and maximize battery life. Here’s a detailed guide on how to charge Li-ion batteries effectively and safely.

Understanding Li Ion Battery Charging

- Basics of Lithium-Ion Batteries:

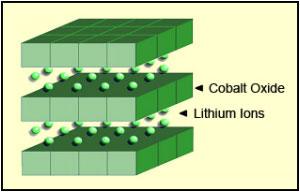

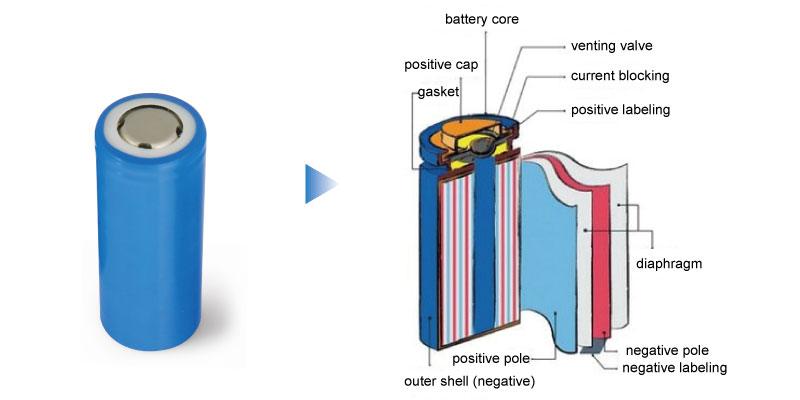

- Chemistry and Charging: Li-ion batteries store energy through the movement of lithium ions from the positive electrode (cathode) to the negative electrode (anode) during discharge and back when charging. Charging a Li-ion battery involves applying an external electric current to reverse the natural discharge process.

- Charging Phases:

- Phase 1 – Constant Current (CC): The battery is charged at a constant current until it reaches its peak voltage, typically around 4.2 volts per cell.

- Phase 2 – Constant Voltage (CV): Once the peak voltage is reached, the charging voltage is held constant while the current gradually decreases until it’s sufficiently low, indicating that the battery is fully charged.

Proper Charging Techniques

- Using the Right Charger:

- OEM Chargers: Always use the charger that comes with your device or one that the manufacturer recommends. These chargers are specifically designed to match the electrical requirements of the battery, ensuring safe and efficient charging.

- Avoid Cheap Alternatives: Low-quality chargers may not regulate voltage and current appropriately, which can lead to overcharging, significantly reducing battery life and increasing the risk of overheating or explosion.

- Optimal Charging Conditions:

- Ambient Temperature: Charge Li-ion batteries at room temperature. Extreme temperatures can affect battery performance and safety, with hot conditions increasing the risk of thermal runaway.

- Partial Charging: Unlike nickel-based batteries, Li-ion batteries do not have a charge memory, so frequent full discharges are not necessary and can actually be detrimental. It’s better to charge the battery partially and frequently.

Safety Tips and Maintenance

- Monitoring During Charging:

- Avoid Overnight Charging: Even though most modern chargers stop charging when the battery is full, it’s safer not to leave batteries charging unattended for extended periods, especially overnight.

- Physical Inspection: Regularly inspect the battery for any signs of damage, such as swelling, heat, or leakage. If any of these signs are present, stop using the battery and replace it.

- Long-Term Health of the Battery:

- Storage: If you need to store your Li-ion battery for an extended period, do so at a 40-50% charge level. Storing a battery either fully charged or fully discharged can speed up its degradation.

- Calibration: While not necessary every charge cycle, periodically letting the battery discharge to around 20% then charging it fully can help calibrate battery gauge sensors.

Himax Electronics: Enhancing Battery Charging Safety and Efficiency

Himax Electronics is dedicated to improving the safety and longevity of Li-ion batteries through innovative technologies and smart solutions:

- Advanced Battery Management Systems:

- Himax BMS technologies ensure optimal charging by precisely managing the amount of current and voltage delivered to the battery throughout the charging cycle. This not only protects the battery from overcharging but also optimizes its overall health and efficiency.

- Cutting-Edge Charger Designs:

- Himax develops chargers that adapt to the needs of Li-ion batteries, incorporating features such as temperature control, voltage regulation, and smart cutoff systems. This proactive approach ensures that the batteries are charged in the safest way possible, enhancing user safety and battery longevity.

Advanced Charging Technologies and Battery Care with Himax Electronics

Himax Electronics is not only at the forefront of battery management systems but also pioneers in the development of advanced charging technologies that enhance both safety and efficiency. Let’s delve deeper into their contributions and provide additional maintenance tips to ensure the optimal performance of lithium-ion batteries.

Innovative Charging Solutions by Himax Electronics

Himax Electronics has developed several key technologies that make charging lithium-ion batteries safer and more efficient:

- Smart Charging Algorithms:

- Adaptive Charging: Himax chargers use algorithms that adapt the charging rate based on the battery’s current capacity, its temperature, and its age. This adaptive charging helps maximize battery life by avoiding stress while still ensuring efficient charging times.

- Pulse Charging: This technique involves charging the battery in short bursts, which can help reduce heat build-up and minimize the risk of damaging the battery, thereby extending its overall lifespan.

- Integrated Safety Features:

- Multi-Level Protection: Himax’s charging devices come equipped with several layers of protection, including over-voltage, over-current, and over-temperature protection. These safety features ensure that the battery remains within safe operating parameters, drastically reducing the risk of accidents.

- Automatic Cut-Off: Himax chargers are designed to automatically cut off the power once the battery is fully charged. This prevents overcharging, which is one of the key contributors to lithium-ion battery degradation and potential failure.

Maintaining Your Li Ion Battery

Proper maintenance of lithium-ion batteries can significantly extend their operational life and maintain their performance. Here are additional tips:

- Regular Cleaning:

- Battery and Device Contacts: Keep the battery contacts and the contacts on the device clean. Accumulated dirt or debris can cause poor connection and increased resistance, leading to potential overheating.

- Use a Dry Cloth: Clean the contacts gently with a dry cloth. Avoid using any liquids or abrasive materials that could damage the contacts or the battery casing.

- Avoid Extreme Discharging:

- Keep Charge Levels Optimal: Frequently allowing your battery to discharge completely can shorten its lifespan. Try to keep the battery charged between 20% to 80% to optimize its lifespan and maintain good health.

- Use Quality Accessories:

- Certified Accessories Only: Always use accessories that are certified by the device manufacturer. Non-certified accessories might not match the specific power requirements of your battery, potentially leading to damage.

- Software Updates:

- Device Updates: Keep your electronic devices updated. Manufacturers often release software updates that optimize battery usage and improve charging strategies based on the latest research and feedback.

Conclusion: Charging Forward with Himax Electronics

Himax Electronics continues to lead the way in lithium-ion battery technology, providing solutions that enhance the safety, efficiency, and longevity of batteries across various applications. By integrating advanced charging technologies and robust safety features, Himax is helping to shape a future where battery reliability and performance meet the demands of an increasingly energy-dependent world.

Whether for consumer electronics, automotive applications, or industrial uses, embracing the best practices for charging and maintenance as recommended by leaders like Himax ensures that your lithium-ion batteries deliver optimal performance throughout their service life. For more information about battery care or to explore Himax’s range of innovative products, visit their website or contact their support team.