A research team from the Skoltech Energy Center, led by Distinguished Professor and director of the center Artem Abakumov, secured a patent for high-capacity cathode materials in lithium-ion batteries made from layered nickel-rich transition metal oxides, as well as a new hydrothermal microwave-assisted approach for their production.

The new method is faster and cheaper, and the cathode material itself will last about 10% longer than those available on the market. The technology will assist in developing electric transport in Russia more effectively.

A paper presenting the results is published in the Journal of Power Sources.

“We use hydrothermal microwave-assisted treatment to coat spherical particles of the precursor of cathode material with a thin layer of cobalt hydroxide. Then, its high-temperature lithiation results in a concentration gradient, formed in the near-surface layer, and a unique morphology—the primary particles are located radially in the agglomerate, and not randomly, as is the case with other materials available on the market,” said Senior Research Scientist Alexandra Savina, a co-author of the patent and the article.

At the first stage, the team obtained a hydroxide precursor (a substance involved in the reaction leading to the formation of another substance), where nickel, manganese, and cobalt cations are homogeneously mixed at the atomic level. Then its suspension with an aqueous solution of carbamide and a cobalt source was placed in a hydrothermal microwave reactor, where it was processed for about 15 minutes.

After that, the team obtained a precursor covered with a uniform cobalt-enriched shell. At the stage of high-temperature lithification, the precursor is mixed with a lithium source and subjected to heat treatment at high temperatures. Now, instead of the microwave processing stage, the co-precipitation method is mainly used on the market, which takes more than 12 hours.

“The formation of a concentration gradient, combined with a unique morphology, provides several advantages—stability of the material and its high capacity at different cycling rates. Thanks to our material, the lithium-ion batteries will work about 10% longer. In addition, we use cheap reagents—carbamide (urea),” Savina added.

Developing advanced energy storage technologies is one of the key scientific and technological tasks in Russia.

Earlier, the government of the Russian Federation approved a roadmap titled “Technologies for creating electricity storage systems, including portable ones” and a concept for the development of production and use of electric transport in Russia up to 2030, which are aimed at accelerating technological development and achieving leading positions in the world in this field.

The Skoltech research team and the startups created at the Institute have been actively working for several years to address the tasks stipulated in the roadmap.

“Today, Skoltech is the largest intellectual property holder in oxide cathode materials in Russia, which will pave the way for the production of energy storage devices in the Russian Federation. Our center is actively developing both new cathode materials and more efficient technologies for their industrial production,” said Abakumov.

“The largest portion of the expense associated with an electric vehicle comes from its battery, and within that battery, the most significant contributor to the overall cost is the cathode material. Consequently, achieving even a 10% decrease in the production costs of the cathode material, while still preserving its capacity and power attributes, serves as a crucial benchmark for enhancing market competitiveness.”

The authors point out that one of the roadmap’s targets is to produce cells with a maximum energy density of 260 watt-hours per kilogram (Wh/kg), but already now the team is producing prototypes of cells with a specific energy intensity of more than 250 Wh/kg, and when switching to the next-generation material, it can be increased to 300 Wh/kg.

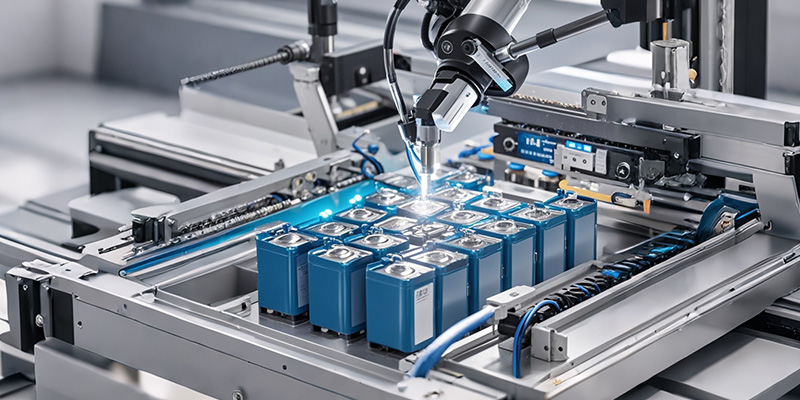

In addition, this year Skoltech researchers expect to launch Russia’s first roller kiln for high-temperature precursor lithiation with a capacity of up to 85 tons per year. The center has already started to construct a new precursor production plant with a capacity of 20 tons per year, which will be fully automated at all stages of the technological process.

The initial data for the new project are obtained during the operation of a pilot plant of up to 10 tons of precursor per year, assembled with Russian components. These projects involve the competencies of the Skoltech-born startup Rustor—a small-scale technological company.

With the help of the production line, which is currently being created, Rustor plans to bring new nickel-rich cathode materials to the market to use them in the field of electric mobility, as well as materials that have been created with specific requirements for unmanned aerial vehicles in mind.

Among the co-authors are two young scientists: Lucia Sitnikova, a Ph.D. student from the Materials Science and Engineering program, and Ekaterina Dolzhikova, a master’s student from the Materials Science program and a graduate of the first cohort of the joint bachelor’s degree between Skoltech and the D. I. Mendeleev Russian Technical University in the Materials for Energy Storage and Conversion program. Dolzhikova began work on the improved cathode material as part of the preparation of her bachelor’s degree thesis.

“In the second year of study, we started working with cathode materials with a core-shell structure. I really liked this topic, so I had no doubt where to continue my studies. This program and the research group have given me a lot: incredible knowledge, a patent, a joint article in a prestigious journal, and career growth. I learned how to work with equipment, reagents, and the best microscopes. I would like to devote even more time to this,” Dolzhikova noted.

More information: Lyutsia A. Sitnikova et al, Improving electrochemical performance of Ni-rich layered cathode material with combining Co-enriched compositional gradient and radial microstructure, Journal of Power Sources (2024). DOI: 10.1016/j.jpowsour.2024.234302

Journal information: Journal of Power Sources

Provided by Skolkovo Institute of Science and Technology