In lithium battery systems equipped with RS485 communication BMS, users sometimes notice that the state of charge (SOC) reading is not accurate right after the battery is first assembled or partially charged. The most common question we hear at Shenzhen Himax Electronics Co., Ltd. is:

“Why do I need to fully charge the battery before the BMS can show the correct SOC?”

The answer lies in how the BMS measures and calibrates the SOC — and how the cells inside the battery behave during charging and balancing.

1. Understanding SOC (State of Charge)

The State of Charge (SOC) represents how much energy remains in a battery compared to its full capacity. It’s typically expressed as a percentage:

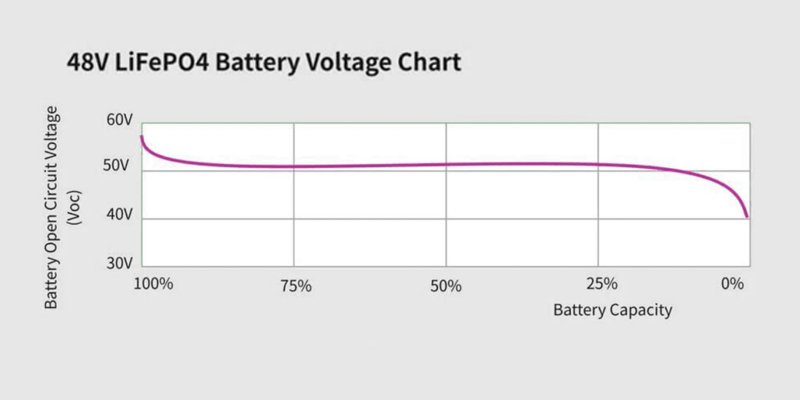

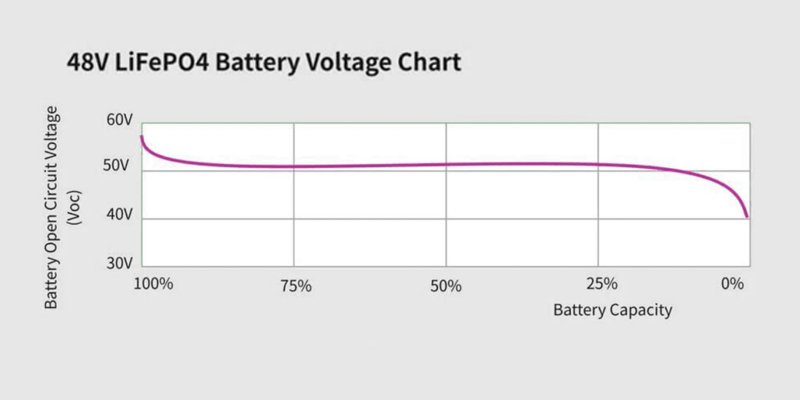

However, SOC is not directly measurable — it’s an estimated value calculated by the BMS based on voltage, current, and time (known as coulomb counting).

Because of this, the SOC accuracy depends on precise calibration between the battery’s actual capacity and the BMS’s internal calculation.

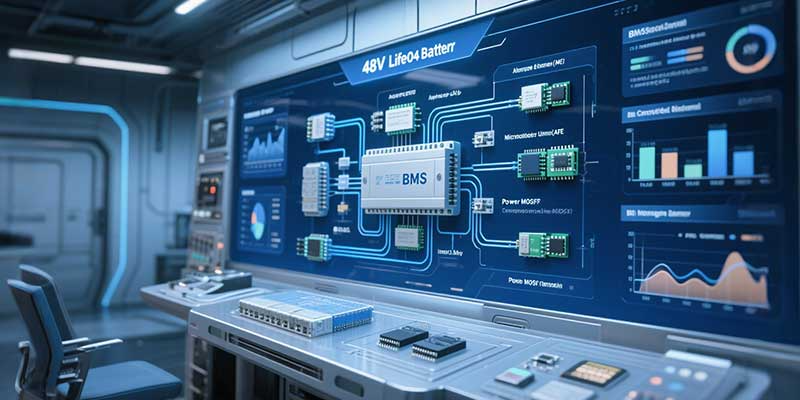

2. How the RS485 BMS Calculates SOC

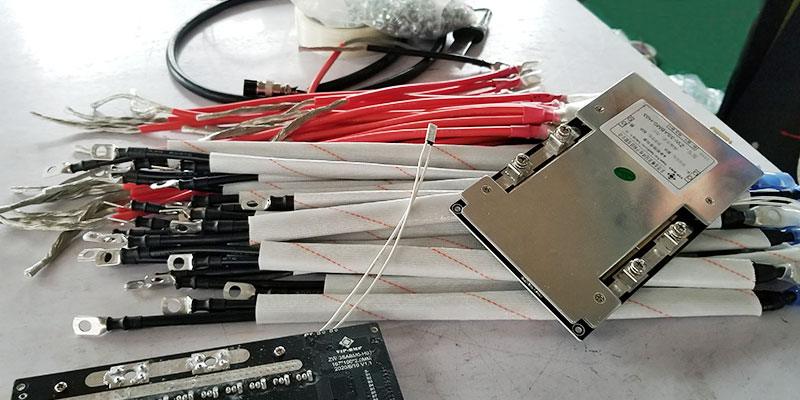

A BMS with RS485 communication is designed to collect real-time data from the battery pack — such as:

Total voltage

Current flow (charge/discharge)

Cell voltages and temperatures

Remaining capacity (Ah)

It then communicates these values to the host system, inverter, or display screen.

But when the BMS is first installed or after deep discharge, its internal SOC counter may not match the real battery capacity. The only way for the BMS to “learn” the true full capacity is through a complete charge calibration cycle.

3. Why Full Charging Is Necessary for Accurate SOC

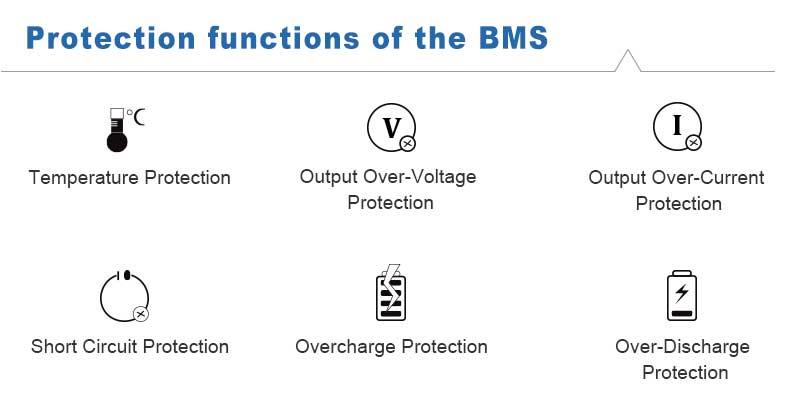

There are three key reasons why full charging allows the BMS to correct and stabilize the SOC reading:

(1) Cell Voltage Balancing

During charging, the BMS equalizes the voltage of each cell through its balancing circuit.

If the cells are not balanced, some may reach their maximum voltage earlier than others, causing the pack voltage to rise unevenly.

A full charge ensures that all cells reach their upper voltage limit (e.g., 4.20V per cell), which provides a clear reference point for the BMS to mark “100% SOC.”

(2) Calibration of Coulomb Counting

The BMS tracks how much current enters or leaves the battery to estimate capacity. Over time, this method accumulates small measurement errors.

A full charge helps the BMS reset or recalibrate the coulomb counter, aligning the calculated capacity with the actual stored energy.

(3) Accurate SOC Synchronization with RS485 Data

When using RS485 communication, the SOC data sent to other devices — such as an inverter, controller, or monitoring system — must match the real battery condition.

A full charge establishes a reliable reference point for 100% SOC, ensuring that the system displays consistent and accurate information across all devices.

4. What Happens If the Battery Is Not Fully Charged

If a lithium battery with an RS485 BMS is not fully charged:

The SOC may drift over time because the BMS cannot confirm its upper voltage reference.

The system may show incorrect SOC readings, such as 85% when the battery is already full or 0% when capacity remains.

In energy storage systems, the inverter may misinterpret SOC, leading to early cutoffs or incomplete charging cycles.

At Shenzhen Himax Electronics Co., Ltd., we’ve seen cases where customers believed their battery capacity was lower than expected — but after a full charge and balance cycle, the SOC corrected itself automatically.

5. How to Perform the Initial Calibration

To ensure accurate SOC readings for RS485 communication BMS packs, follow these steps:

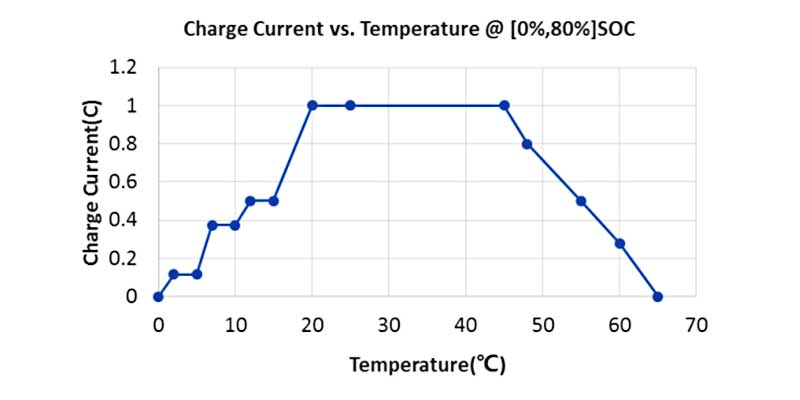

Fully charge the battery until it reaches the rated voltage (e.g., 16.8V for a 4S pack, 29.4V for a 7S pack).

Keep charging for an additional 30–60 minutes to allow cell balancing to complete.

Once the pack is balanced and current drops near zero, the BMS sets that point as 100% SOC.

Afterward, perform a full discharge to the cut-off voltage to help the BMS calibrate the lower limit (0% SOC).

This process ensures the RS485 BMS communicates an accurate and reliable SOC to your monitoring equipment.

6. Final Thoughts

A full charge is not just about topping up energy — it’s about calibration and synchronization. For RS485 communication BMS systems, this step allows the controller to correctly recognize the real capacity of the battery and prevent misleading readings.

At Shenzhen Himax Electronics Co., Ltd., we design our smart lithium battery packs and RS485 BMS systems with advanced balancing and high-accuracy SOC algorithms to minimize drift and improve precision. Still, performing a full charge during the initial setup or after long storage remains an essential step to ensure the most accurate performance data.

Proper calibration guarantees that your system always knows the true energy status of the battery — delivering reliability, safety, and efficiency for every application.