Why “Overcharged-Low Discharge” and “Undercharged-High Discharge” Happen in Lithium Battery Packs

In the real-world application of lithium-ion battery packs, performance issues like overcharged-low discharge and undercharged-high discharge are common causes of customer complaints. These phenomena can severely impact the performance evaluation, safety, and overall user experience of battery systems.

This article aims to break down these two issues in simple, professional terms — explaining their symptoms, root causes, potential risks, and possible solutions. Whether you’re a battery designer, manufacturer, or end-user, this guide can help you better understand and manage these challenges.

1. The Overcharged-Low Discharge Issue: Hidden Capacity Loss and Safety Risks

What Is Overcharged-Low Discharge?

The term overcharged-low discharge refers to a mismatch between the battery pack’s charging and discharging capacity. For example, a pack rated at 100Ah may appear to charge up to 105Ah, but during discharge, it only delivers 95Ah. This leads to confusion about the battery’s actual capacity and performance.

What Causes It?

There are several technical reasons behind this issue:

Inconsistent Cell Aging: In a multi-cell battery pack, not all cells age at the same rate. Some cells degrade faster due to manufacturing differences or usage conditions. During charging, weaker cells reach their maximum voltage sooner, causing the Battery Management System (BMS) to halt charging to prevent overcharging — even though other cells are not fully charged. During discharge, these weaker cells also drop voltage faster, again prompting the BMS to stop discharging early.

Internal Resistance Differences: Cells with higher internal resistance show a faster voltage rise during charging and a quicker drop during discharging. This leads to misleading voltage readings that cause early cutoffs by the BMS.

Uneven Temperature Distribution: Cells operating in cooler areas of the pack show reduced electrochemical activity, which limits their ability to charge or discharge fully. These cells become bottlenecks, reducing the usable capacity of the entire pack.

What Are the Risks?

Misleading Capacity Indications: Users may believe the battery has more capacity than it can safely deliver.

Accelerated Aging: Cells that are frequently undercharged or prematurely stopped during charge/discharge cycles age more quickly.

Safety Hazards: In extreme cases, deep discharge of weak cells can lead to lithium plating or thermal runaway — a dangerous safety concern.

2. The Undercharged-High Discharge Issue: Algorithm Errors and Temperature Effects

What Is Undercharged-High Discharge?

This is a phenomenon where a battery appears to charge less than its rated capacity but releases more during discharge. For instance, it might charge to 95Ah but discharge 98Ah. This seems counterintuitive but is observed in many battery pack applications.

What Causes It?

BMS Calibration Errors: The BMS may inaccurately estimate the battery’s state of charge (SOC), leading to an early stop during charging or extended discharging.

Low-Temperature Charging: In cold environments, lithium-ion mobility is reduced, decreasing charge acceptance. However, when the temperature rises during discharging, the cells can perform normally, appearing to release more energy than they received.

Balancing Circuit Interference: During charging, passive balancing circuits may drain energy from higher-voltage cells to equalize the pack, lowering the total reported charge.

What Are the Risks?

Unnecessary Service Complaints: Users may believe the battery did not charge properly and request service or replacement.

Over-Discharge Risk: The battery may discharge below safe limits due to inaccurate SOC readings.

Structural Damage to Electrodes: Repeated over-discharge or undercharge can degrade the internal structure of the battery cells, shortening lifespan.

3. The Root Cause: Inconsistency Among Cells

At the core of both problems is one major factor: cell inconsistency. Variations between individual cells lead to imbalances during both charging and discharging. These inconsistencies stem from three main areas:

Manufacturing Variability: Even small differences in electrode coating thickness or electrolyte saturation can result in performance variation between cells.

Uneven Usage Conditions: Non-uniform heat distribution, differing current paths, and environmental conditions cause individual cells to age at different rates.

Diverging Aging Speeds: Some cells may deteriorate faster due to localized overheating, repeated overcharge/discharge cycles, or physical stress.

4. Effective Solutions: From Design to Intelligent Management

Addressing these problems requires a multi-pronged strategy from the initial cell selection to long-term system management.

Cell Grading and Grouping

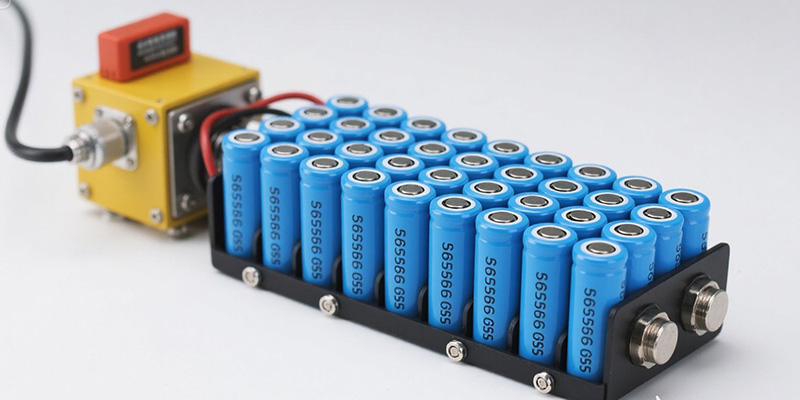

Before assembling the pack, cells should be sorted based on their capacity, internal resistance, and self-discharge rate. Grouping closely matched cells reduces imbalance and improves the performance of the entire pack.

Advanced Balancing Technologies

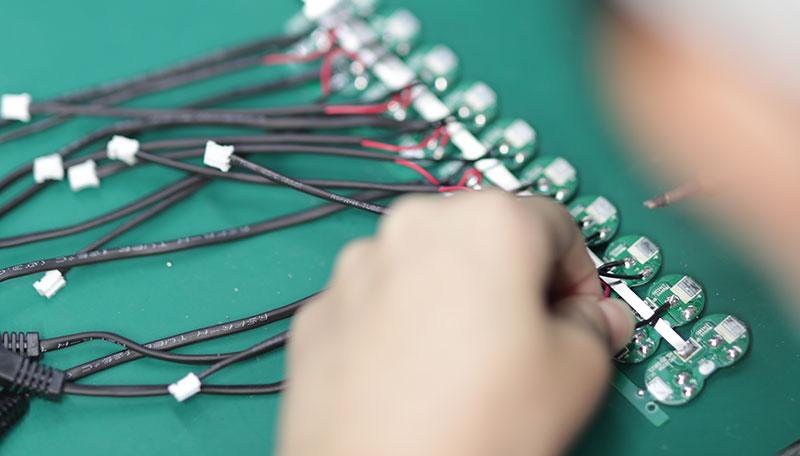

Active Balancing: Transfers energy from higher-voltage cells to lower-voltage ones using inductors or capacitors. This improves pack efficiency but increases system complexity and cost.

Passive Balancing: Uses resistors to bleed excess energy from stronger cells. While simpler and cheaper, it wastes energy and is less efficient.

Smarter BMS Algorithms

Combine Coulomb Counting (Ah integration) with Open Circuit Voltage (OCV) methods for more accurate SOC estimations.

Monitor individual cell voltages and temperatures in real time, and trigger balancing actions if the voltage gap exceeds set thresholds (e.g., >0.3V).

Better Thermal Management

Use liquid cooling or forced air systems to maintain a uniform temperature across all cells.

Avoid localized hotspots or cold zones that can accelerate aging or reduce performance.

5. Conclusion: Focus on Consistency, Intelligence, and Control

The overcharged-low discharge scenario often indicates the presence of weak cells that limit the overall capacity and raise safety concerns. The undercharged-high discharge issue is usually linked to BMS miscalibration or environmental factors like low temperature.

Ultimately, both issues can be traced back to inconsistencies between individual cells. The best long-term solution lies in:

Careful matching of cells at the factory,

Applying dynamic balancing methods, and

Employing smart BMS algorithms with real-time monitoring.

As lithium-ion battery packs technologies evolve, advanced sorting equipment, AI-powered BMS systems, and efficient thermal designs will become key tools in minimizing these customer complaints and maximizing battery performance.

By implementing these strategies, manufacturers can build safer, longer-lasting, and more reliable lithium-ion battery packs — delivering real value to customers in today’s increasingly electrified world.

Reference: “Why Do Battery Packs Show Overcharged-Low Discharge and Undercharged-High Discharge?” by Buyan (Original article in Chinese).