HIMAX’S 24V 100Ah LIFEPO4 MARINE BATTERY IS REDEFINING RELIABILITY AND PERFORMANCE FOR MODERN ANGLERS

For the dedicated angler, a day on the water is a pursuit of passion, often marred by the persistent, low-frequency hum of a generator or the nagging anxiety of a dying trolling motor battery. The heart of any modern fishing vessel is its electrical system, powering everything from the silent electric trolling motor to the sophisticated fish finders and livewell pumps that are essential for a successful catch. For years, this heart has been powered by heavy, limited lead-acid batteries, a technology with roots in the 19th century. This era is now decisively over. HImax, a leading innovator in advanced energy storage, is spearheading this transformation with its robust 24V 100Ah LiFePO4 (Lithium Iron Phosphate) marine battery, a product engineered specifically to meet the harsh demands of the marine environment and the high expectations of today’s fishermen.

The critical question for boat owners is no longer merely about upgrading, but about how a specific battery technology can fundamentally enhance their entire fishing experience. It is about why the structural and chemical choices made in a battery’s design—such as the decision to use a rigid, protective outer casing as detailed in HImax’s own technical comparisons—are non-negotiable for safety and performance at sea. The shift to LiFePO4 is a paradigm change, moving from a component that is a constant concern to one that is a pillar of reliability.

Why the Outer Casing is a Critical Safety Feature in a Marine Environment

When analyzing battery options, the distinction between a cell with a rigid outer casing and one without is paramount. HImax’s 24V 100Ah battery utilizes a high-grade, ruggedized casing, a design choice that directly addresses the unforgiving nature of the marine world.

In the confined, often wet, and dynamically shifting space of a boat’s bilge or battery compartment, a battery is susceptible to physical impact, vibration, and accidental short-circuiting from shifting tools or loose wiring. A flexible pouch cell, while space-efficient, is vulnerable to puncture and deformation. The rigid metal casing of the HImax LiFePO4 battery provides essential Mechanical Robustness, acting as a shield against these hazards. It protects the sensitive internal jellyroll from impacts that could cause an internal short circuit—a primary failure mode that can lead to thermal runaway.

Furthermore, this casing serves as a crucial Containment Vessel. In the highly improbable event of an internal cell failure, the robust casing helps to contain the effects, preventing a single point of failure from escalating. For an angler miles from shore, often alone on the water, this intrinsic safety-by-design is not a luxury; it is a fundamental requirement. The HImax casing ensures the battery is a self-contained, secure unit, much like the watertight compartments in a hull itself.

How Superior Cycle Life and Depth of Discharge Translate to Uninterrupted Fishing

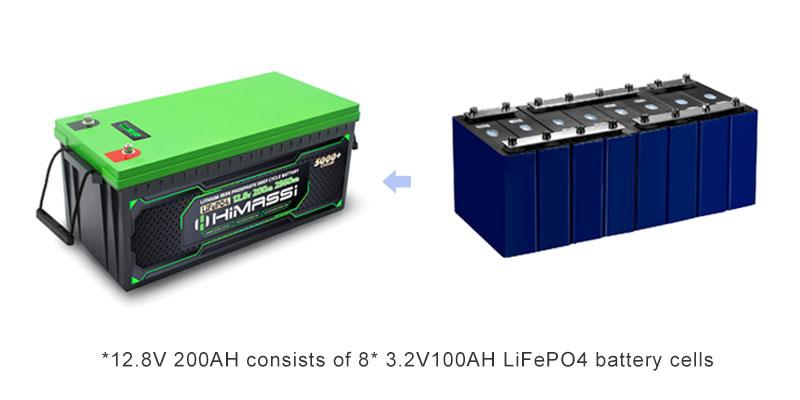

The chemistry of Lithium Iron Phosphate is the cornerstone of this battery’s legendary longevity. While a high-quality lead-acid or AGM battery might offer 500-800 cycles before its capacity degrades to 80%, the Himassi 24V 100Ah LiFePO4 battery is rated for 3,500 to 5,000 cycles. This translates not to years, but to decades of reliable service for the average weekend angler, effectively making it a one-time investment for the lifespan of the boat.

More critically for a day on the water is the Depth of Discharge (DOD). Lead-acid batteries suffer from rapid degradation if discharged beyond 50% of their capacity. This means a 100Ah lead-acid battery only offers a practical 50Ah of usable energy. The HImax LiFePO4 battery, however, can be safely discharged to 100% of its capacity (and routinely to 80-90% for even longer life) without harm. This effectively doubles or even triples the usable runtime compared to a lead-acid battery of the same nominal rating.

For a fisherman, this means a full day of trolling against the current, running multiple livewell pumps, and powering high-definition sonar and radar units without the slightest concern about depleting the battery to a damaging level. It provides the peace of mind to venture further and stay out longer, knowing the power reserve is both substantial and accessible.

Why Weight Savings and Power Stability are Game-Changers for Vessel Performance

The impact of weight on a boat’s performance is a fundamental principle of naval architecture. A typical 24V 100Ah lead-acid battery bank can weigh over 120 pounds (55 kg). The equivalent HImax LiFePO4 system weighs approximately 50-55 pounds (23-25 kg). This reduction of nearly 70 pounds is transformative.

This dramatic weight saving has a cascading positive effect:

Improved Fuel Efficiency: The main engine uses significantly less fuel to get the boat on plane and to maintain cruising speed.

Enhanced Handling and Stability: A lighter boat is more responsive, planes more easily, and sits higher in the water, improving stability and ride quality.

Increased Payload Capacity: The saved weight can be reallocated to fuel, gear, or an extra passenger.

Beyond weight, the power delivery is superior. Lead-acid batteries experience voltage “sag” as they discharge; as the battery depletes, the voltage drops, causing a trolling motor to lose thrust and electronics to behave erratically. The HImax LiFePO4 battery maintains a consistently high voltage throughout almost its entire discharge cycle. This means a trolling motor delivers full, unwavering power from the first cast until the return to the dock, and all onboard electronics operate with flawless stability.

How Integration and Intelligent Management Ensure Worry-Free Operation

The “how” of integrating this power source is engineered for simplicity and intelligence. The HImax battery is not just a collection of cells in a case; it is a complete power system. It features an integrated Battery Management System (BMS) that acts as an uninterruptible guardian. This sophisticated system provides:

Cell Balancing: It ensures all individual cells within the 24V pack charge and discharge uniformly, maximizing performance and lifespan.

Multi-Layer Protection: The BMS actively guards against over-charging, over-discharging, over-current, short circuits, and high/low-temperature operation.

Communication Capabilities: Many models offer Bluetooth connectivity, allowing anglers to monitor the battery’s state of charge, health, and power consumption in real-time directly on a smartphone or chartplotter.

This plug-and-play design, with marine-grade terminals, allows for a straightforward installation as a direct replacement for outdated systems or as the core of a new build. Its versatility makes it the single solution for a wide array of marine applications, from providing relentless power to a 24V trolling motor to serving as a robust “house” battery for all onboard electronics and critical systems like bilge pumps.

In the world of recreational fishing, where success and safety are inextricably linked to dependable technology, the standard for power solutions must be uncompromising. The transition to lithium is more than an upgrade; it is a fundamental shift in capability and confidence. By meticulously engineering its 24V 100Ah marine battery around the core principles of safety through a robust outer casing, unparalleled longevity via LiFePO4 chemistry, and practical superiority through lightweight design and stable power output, HImax has established a new benchmark for marine energy. For the modern angler, this battery is more than a component—it is the silent, reliable, and powerful partner that turns a simple boat into a truly capable fishing platform, enabling longer days, more catches, and absolute confidence on the water.