Choosing the Right Lithium Battery for Robotics: Critical Requirements Explained

In the world of robotics, power is everything. Whether you’re building an autonomous mobile robot (AMR), a robotic arm, or a high-performance drone, your robot’s efficiency and reliability depend heavily on one critical component: the battery. Among the various battery chemistries available, lithium-ion (Li-ion) batteries are the go-to choice thanks to their high energy density, lightweight construction, and good cycle life.

However, not all lithium batteries are created equal—and selecting the right one for your robot requires a careful evaluation of several critical factors. In this article, HIMAX, a trusted supplier of lithium battery technology, walks you through the essential requirements for robotics power systems.

1. Voltage and Capacity of Lithium Battery: The Foundation of Power

The voltage of the battery must match your robot’s motor and electronic requirements. Common configurations include:

- 7.4V (2S)– Suitable for small robots or lightweight electronics.

- 11.1V (3S)– Great for mid-sized mobile robots.

- 14.8V (4S)– Ideal for larger robots with higher power demands.

Battery capacity, measured in amp-hours (Ah) or watt-hours (Wh), determines how long your robot can operate on a single charge. Higher capacity means longer runtime—but also greater weight. HIMAX engineers help you find the best balance for your application.

2. Discharge Rate (C-Rating): Meeting Power Demands

The C-rating defines how quickly a battery can discharge energy. For robotics, especially applications involving motors and actuators, this is a critical factor.

- Example: A 14.8V 20Ah lithium battery with a 5C rating can deliver up to 100A continuous current.

If your robot’s motors demand high current during acceleration or under heavy load, choose a battery with a high C-rating (5C or more) to ensure stable performance and prevent voltage sag.

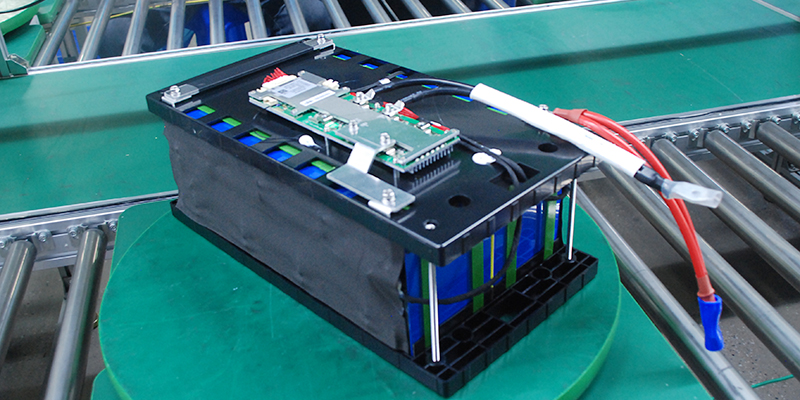

3. Battery Management System (BMS) of Lithium Battery: Safety First

A Battery Management System is essential for protecting your battery and robot. HIMAX integrates advanced smart BMS modules that provide:

- Over-voltage and under-voltage protection

- Over-current and short-circuit protection

- Cell balancingfor long-term reliability

- Temperature monitoring

- Communication interfaces(UART, CAN, I²C) for system integration

For example, the 4S 100A Smart BMS is ideal for high-current robotics platforms with real-time monitoring capabilities.

4. Thermal Management: Keeping Cool Under Pressure

Lithium batteries generate heat during high-current use. Without proper thermal control, overheating can cause performance degradation or even battery failure.

- HIMAX battery packs include thermal protection and venting features.

- Active or passive cooling solutionscan be tailored to your robot’s environment.

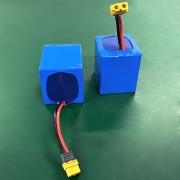

5. Size and Weight of Lithium Battery: Fit Within Design Constraints

Robots have limited space and strict weight budgets. HIMAX designs custom lithium battery packs using high-density cells like 18650 or 21700 to maximize energy while minimizing volume.

Always ensure:

- The battery physically fitsinto your robot’s chassis.

- Weight does not compromise balance, mobility, or runtime.

6.Cycle Life of Lithium Battery : Powering Long-Term Use

Choose lithium batteries with a high cycle life (500–1000+ cycles) for commercial or industrial robotic platforms. HIMAX sources high-grade cells with long-lasting chemistry for mission-critical applications.

Proper charging and a smart BMS further extend the battery’s service life.

7. Safety and Certification

HIMAX batteries are designed and tested to meet international safety standards. Look for the following certifications when selecting a battery:

- UN38.3(transport safety)

- CE, RoHS, MSDS

- Short-circuit, over-temperature, and explosion protection

Robots operating in sensitive environments must adhere to strict safety protocols—HIMAX helps you stay compliant.

8. Environmental Resistance

For robots in outdoor, industrial, or mobile scenarios, your battery must withstand:

- Vibration and mechanical shock

- Moisture, dust, or splash exposure (IP-rated enclosures)

- Temperature extremes

HIMAX offers ruggedized battery solutions built to endure harsh environments.

Recommended Configuration for Robotics (by HIMAX)

If you’re developing a medium-to-large mobile robot or autonomous system, HIMAX recommends the following:

- Battery Type: Lithium-ion

- Voltage: 14.8V (4S)

- Capacity: 20Ah

- Discharge Rate: 5C (100A continuous)

- Cells: 18650 high-drain industrial cells

- BMS: 4S 100A Smart BMS with CAN/UART

- Certifications: UN38.3, CE, RoHS, MSDS

This combination delivers high power, reliable safety, and excellent lifespan—ideal for robotics integration.

Conclusion

Selecting the right lithium battery for robotics is not just a technical task—it’s a strategic decision. It impacts how long your robot runs, how it performs under load, and how safe it is in operation. By partnering with HIMAX, you gain access to high-performance lithium battery solutions that are purpose-built for robotics innovation.

Power Up Your Robotics Project with HIMAX

HIMAX is a leading manufacturer and supplier of custom lithium-ion battery packs for robotics, industrial automation, and smart mobility. From design to delivery, we engineer power systems that move your technology forward.

Contact us today to get expert support for your robotics battery needs.

Visit us at: www.himaxelectronics.com/www.himaxbattery.com