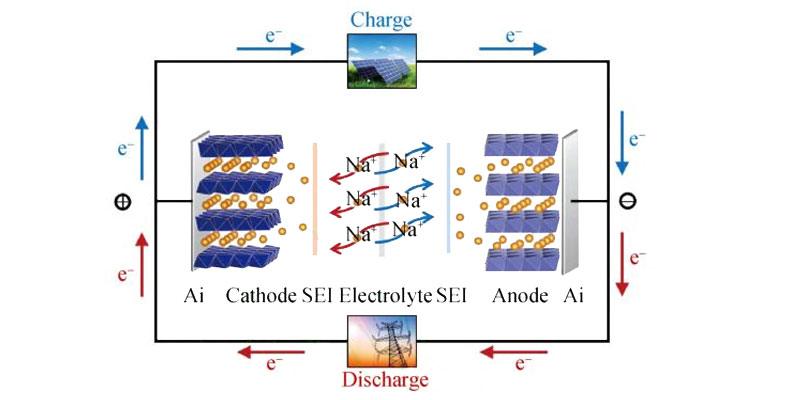

Legions of battery engineers and their supporters have sought for years to build batteries cheaper than the dominant lithium-ion technology, hoping to capture some of lithium-ion’s $50 billion-a-year and growing market. The latest darling contender among researchers, startups, and venture capitalists—sodium-ion batteries—has received much attention after COVID-induced mineral supply chain challenges sent lithium prices on a wild ride.

Still, achieving a low-cost contender may be several years away for sodium-ion batteries and will require a set of technology advances and favorable market conditions, according to a new study in Nature Energy.

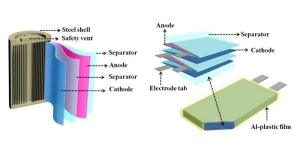

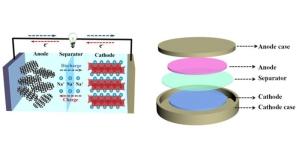

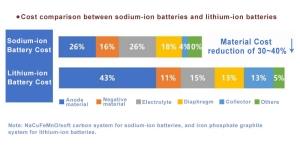

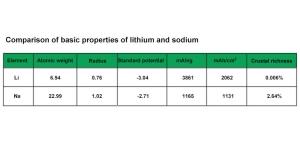

Sodium-ion batteries are often assumed to have lower costs and more resilient supply chains compared to lithium-ion batteries. Despite much potential, sodium-ion batteries still face an uphill struggle. The amount of energy they hold per pound tends to be lower than lithium-ion batteries.

So, possible lower materials prices aside, the cost per unit of energy stored remains higher for sodium-ion batteries. This likely would limit widespread commercial adoption—unless research breakthroughs can be made first. The most fertile areas for advancement are highlighted in the study, the first by a new partnership between the Stanford Doerr School of Sustainability’s Precourt Institute for Energy and the SLAC-Stanford Battery Center.

The new program, STEER, assesses the technological and economic potential of emerging energy technologies and advises “what to build, where to innovate, and how to invest” for the energy transition. The new study evaluated more than 6,000 scenarios to test the robustness of their roadmaps for sodium-ion battery’s competitive potential.

“The price of lithium-ion batteries rose for the first time in 2022, which set off alarms for potentially needing an alternative. Sodium-ion is perhaps the most compelling near-term challenger to lithium-ion, and many battery companies announced plans of major build out of sodium-ion manufacturing, promising pathways to lower prices than the incumbent,” said Adrian Yao, the study’s lead author as well as the founder and team lead of STEER, which began in October 2023 with the support of three offices within the U.S. Department of Energy.

“We recognized that if, when, and how sodium-ion batteries might undercut lithium-ion on price was largely speculative, especially given that the price of lithium-ion continues to fall,” said Yao, a doctoral candidate who returned to academia after eight years of being the founder and chief technology officer of a lithium-ion battery startup now producing its batteries on a large, commercial scale.

Yao’s Ph.D. co-advisors are the new study’s senior authors and the co-directors of STEER: Sally Benson, the Precourt Family Professor in the Department of Energy Science & Engineering in the Doerr School of Sustainability; and William Chueh, an associate professor of materials science in the School of Engineering, of photon science at SLAC, and of energy science and engineering in the Doerr School.

“This sodium-ion study was the perfect undertaking to launch STEER as a new way to guide research and investment toward the technology roadmaps most worthy of pursuit and, perhaps more important, away from ones unlikely to be successful,” Benson said.

Do’s and don’ts for sodium-ion

To compete on price, specifically against a low-cost variant of the lithium-ion battery known as lithium-iron-phosphate, the study highlights several key routes for sodium-ion battery developers. Most important is to increase energy densities without the use of critical minerals. Specifically, developers should target lithium-iron-phosphate energy densities while moving away from nickel. Currently, most leading sodium-ion designs rely on the relatively expensive metal.

“Our primary objective, though, was not predicting specific years for when we expect price parity, but in surfacing the impacts of various market scenarios on the viability of competing technologies,” said Chueh.

“As technologists and investors, we cannot assume that economies-of-scale will always send prices plummeting once a device reaches commercial production. Yes, there will be a learning curve, but here we quantify this curve and show that it isn’t enough on its own,” said Chueh, who is also the director of the Precourt Institute for Energy. “Engineering advances will likely do much more to cut sodium-ion battery costs than simply scaling production.”

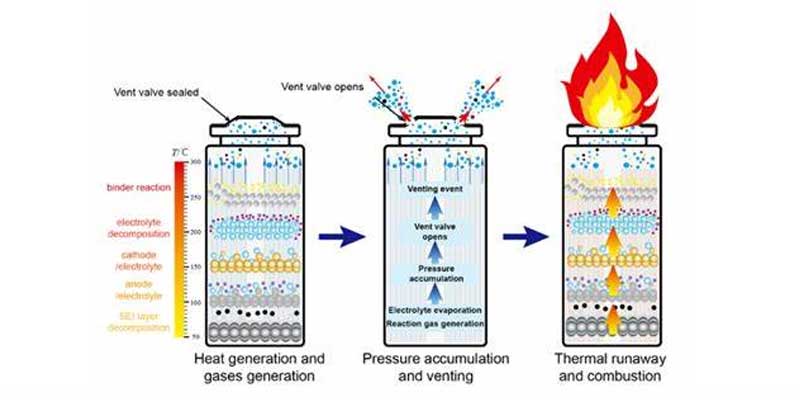

Such advances and new battery chemistries generally are worth pursuing, the researchers said. Continuing to rely so heavily on lithium-ion batteries as more energy storage is needed for the global transition to sustainable energy will pose security, economic, and geopolitical risks.

For example, the study simulates how the competitiveness of sodium-ion would be accelerated if supply shocks were to occur to graphite—a critical material used in lithium-ion batteries where China controls more than 90% of the global supply. In fact, on Dec. 3, 2024 China began to significantly restrict exports of graphite to the United States, while also banning exports of three other critical minerals.

The study also identifies market forces and supply chain conditions that could hurt sodium-ion’s competition with lithium-ion. For example, if lithium prices continue where they are today near historic lows, sodium-ion has a narrower set of technology routes to become price advantageous in the next decade.

“One key thing we learned from industry practitioners is that while battery cell prices are important, technologies only succeed at the systems level, say an electric vehicle or a grid-scale battery energy storage system. That’s why we’re now expanding our scope to provide more holistic perspectives, including understanding the cost of safety and other systems considerations,” said Yao.

Up next

STEER has begun to apply its approach to other technology areas. Its researchers are examining the supply chain of the previously mentioned and often overlooked critical mineral: graphite. Industry executives and Department of Energy leaders advised on the right questions to ask and answer at a roundtable in Washington, D.C. in September. The workshop included more than 40 industry organizations, stitching together the value chain from mining companies to car makers, as well as every graphite manufacturer.

“STEER is able to identify paths with the highest chances of contributing to the energy transition and those likely to lead nowhere thanks to our collaborators in industry, government, and other research institutions,” said Benson. “Our team combines commercial deployment experience, technology roadmapping, and systems thinking.”

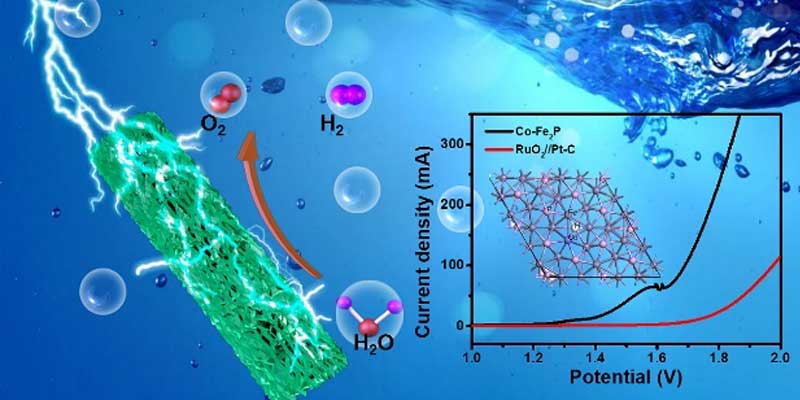

The STEER team also plans to analyze technology roadmaps in long-duration energy storage, as well as other energy transition areas such as hydrogen and industrial decarbonization.