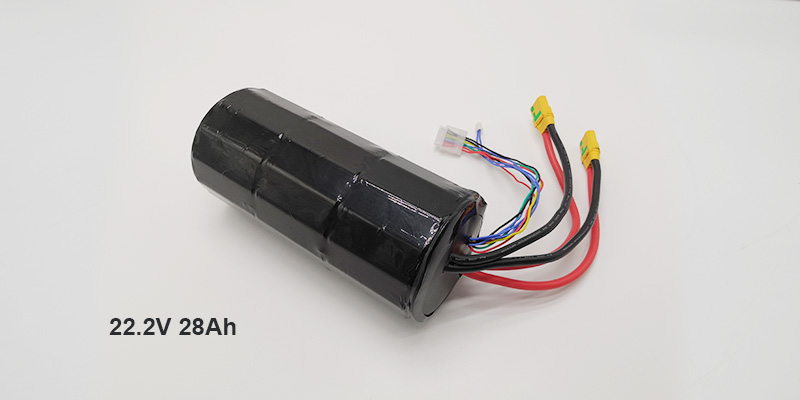

LiFePO4 battery packs are known for their long lifespan, safety, and excellent thermal stability, making them ideal for solar storage, RV systems, marine use, and backup power. However, even these highly durable batteries require periodic attention when stored for extended periods.

At HIMAX Electronics, we provide high-performance LiFePO4 battery packs for industrial and consumer applications, and we always recommend one key maintenance rule during long-term storage:

? Check your LiFePO4 battery at least every 3 months.

Why is this simple step so important? Let’s break it down.

1. Self-Discharge Is Slow—But Still Happens

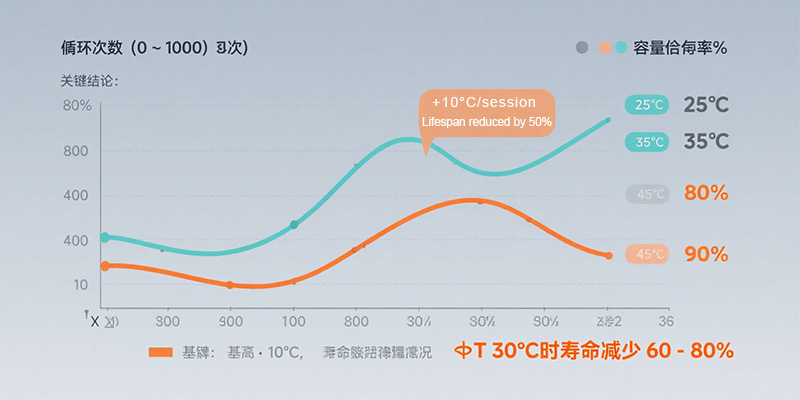

LiFePO4 batteries have a very low self-discharge rate—typically 2–3% per month under ideal conditions. But over time, this adds up. If a battery is stored for a year without checks, it could lose over 30% of its charge, potentially dropping below the safe voltage threshold.

At HIMAX Electronics, we recommend rechecking every 3 months to avoid deep discharge, which can permanently reduce capacity or even render the battery inoperable.

2. Avoid Over-Discharge and Irreversible Damage

LiFePO4 batteries typically operate safely between 2.5V and 3.65V per cell. During long storage, if the voltage drops below 2.5V per cell, it may lead to:

- Internal chemical imbalance

- Lithium plating or copper dissolution

- Capacity loss or failure to recharge

Checking every 3 months ensures voltage levels remain above the critical threshold and allows for recharging if needed.

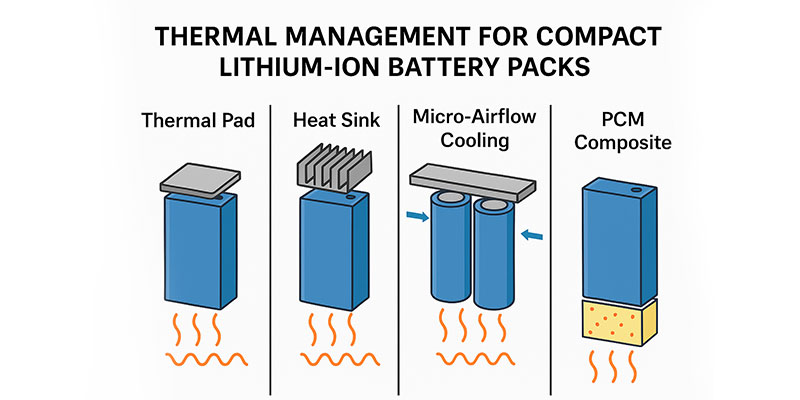

3. Environmental Conditions Can Fluctuate

Even if the battery was stored under optimal conditions (10–25°C), changes in temperature or humidity can accelerate degradation. For example:

- Heat increases self-discharge and internal resistance

- Cold may reduce voltage output and slow recovery

- High humidity can cause corrosion or moisture intrusion

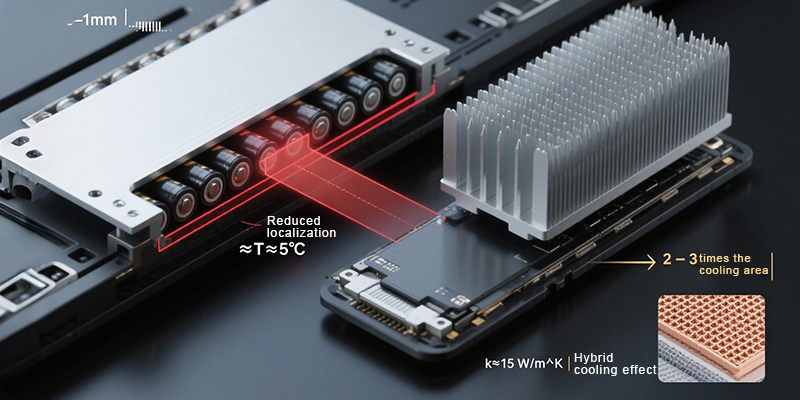

Routine inspections allow you to catch these issues early, especially in off-grid or outdoor storage environments. HIMAX Electronics also offers battery enclosures for climate-sensitive applications.

4. Preserve Calendar Life and Warranty Compliance

Checking the battery periodically isn’t just about performance—it’s about protecting your investment. Failing to inspect batteries could:

- Shorten their overall calendar life

- Void warranty terms due to neglect

- Increase the risk of needing early replacements

HIMAX Electronics encourages scheduled inspections to help our customers get the full value and lifespan from our battery packs.

5. Ensure Instant Readiness in Backup Applications

If your LiFePO4 battery is used for emergency backup, it must be ready at all times. Quarterly checks ensure the system can:

- Start immediately during a power outage

- Deliver sufficient energy for critical equipment

- Safely operate without voltage drops or alarms

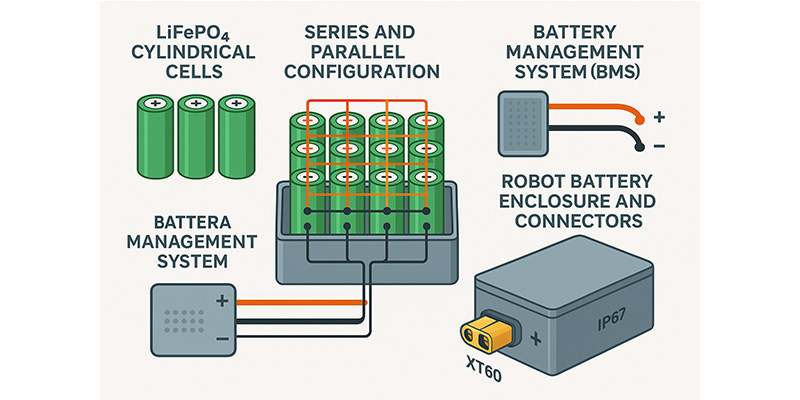

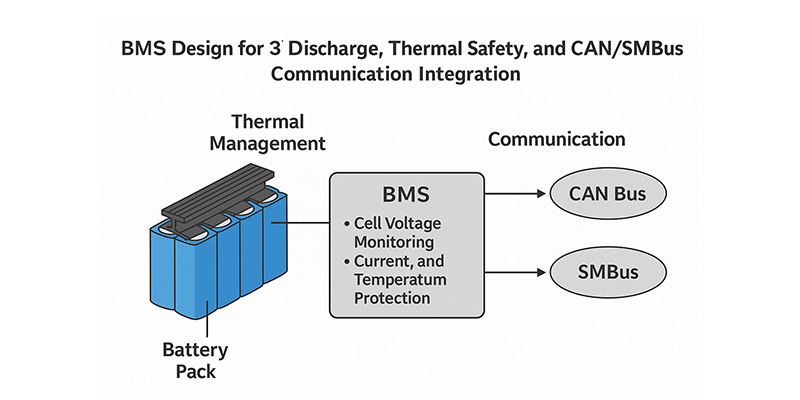

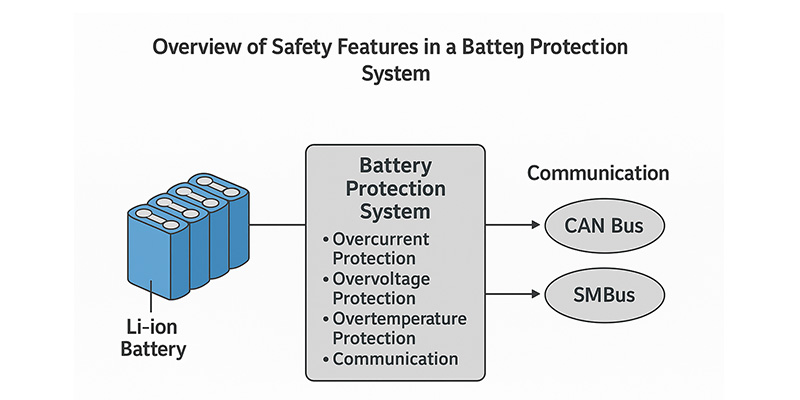

HIMAX Electronics integrates smart BMS (Battery Management Systems) in many of our battery packs, enabling remote voltage checks and alerts for added convenience.

Best Practices for Quarterly Battery Checkups

| Checklist Item | Recommended Action |

| Check Voltage | Recharge if < 3.2V per cell |

| Visual Inspection | Look for swelling, corrosion, damage |

| Check Terminals & Cables | Ensure clean, dry, and tight connections |

| Rebalance SOC (if needed) | Charge to 50% for continued storage |

| Review BMS Logs (if available) | Monitor any error codes or alerts |

HIMAX Electronics Supports Long-Term Performance

At HIMAX Electronics, we don’t just sell batteries—we engineer complete power solutions designed for durability, safety, and convenience. Our LiFePO4 battery packs are built with:

- Smart BMSfor protection and monitoring

- Low self-discharge cellsfor long shelf life

- Documentation and supportfor storage best practices

Need help planning a long-term storage routine? Our engineers are ready to assist you with tailored storage protocols and monitoring tools.

Conclusion

While LiFePO4 batteries are impressively stable during storage, regular maintenance is still essential. By checking your battery every 3 months, you’ll protect it from irreversible damage, extend its service life, and ensure it’s always ready when you need it.

Trust HIMAX Electronics to deliver energy solutions that last—and help you take care of them the right way.