Introduction

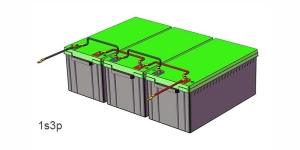

Lithium batteries stand as a cornerstone in modern technology, powering everything from mobile devices to electric vehicles and renewable energy systems. The effectiveness of these batteries(Lifepo4 battery) hinges significantly on the quality and suitability of the connecting cables. This guide not only focuses on selecting the right cables based on load power but also emphasizes the crucial aspects of safety and system efficiency. The introduction sets the stage for the importance of careful cable selection in optimizing battery performance and extending the life of the energy system.

Understanding the Basics of Cable Selection

- Cable Specifications Explained:

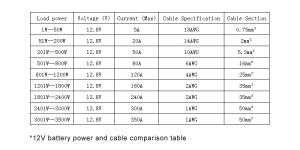

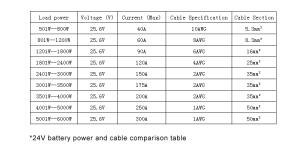

- Size and Gauge: The thickness of a cable, or gauge, is critical as it dictates the amount of current it can safely transport. This section will explain how to choose the right gauge based on the American Wire Gauge (AWG) standard, which inversely correlates the gauge number with the wire diameter.

- Material: While copper is preferred for its lower resistance and superior conductivity, aluminum is considered when weight and cost are factors, despite its approximately 61% conductivity of copper. This part will include a comparative analysis, highlighting scenarios where each material might be preferable.

- Insulation Type: Different insulation materials cater to varying operational demands—PVC is versatile and economical, rubber offers enhanced flexibility and durability, and Teflon is ideal for high-temperature environments. Each material’s properties, applications, and limitations will be discussed in detail.

- Role of Cables in Lithium Battery Systems:

- Power Transmission: Cables are the lifelines that carry the electrical power from the battery to the device or system. This section will explore the dynamics of power transmission, including efficiency factors and how improper cable selection can lead to energy loss.

- Safety Mechanisms: The correct cable not only supports efficient operation but also incorporates safety features to prevent overheating, electrical fires, and other hazards. The importance of choosing cables with adequate insulation and protective coatings to mitigate risks will be emphasized.

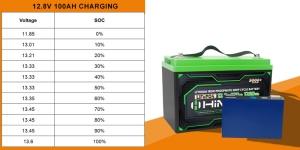

Analyzing Lithium Battery Load Requirements

- Defining Load Power:

- Understanding load power is fundamental in selecting a suitable cable. This subsection will offer guidelines on how to quantify the load power by considering both the operational wattage and the peak power demands of the system.

- Assessing Load Demands:

- Continuous vs. Peak Loads: Differentiating between continuous and peak load requirements is crucial for cable durability and system reliability. Examples of typical loads in residential, commercial, and industrial settings will be provided to illustrate how to cater to each.

- Calculating Load: This part will provide a step-by-step approach to calculating the required cable gauge using formulas and considering factors like total wattage and voltage of the system to ensure that all technical parameters are met without over-specifying.

Choosing Cables: Key Considerations

- Current Carrying Capacity:

- It’s vital to opt for cables that can handle higher currents than the system maximum to accommodate any unforeseen power surges or incremental load increases. This section will include a discussion on safety margins and how they affect cable choice.

- Voltage Drop and Line Losses:

- Voltage drop across the length of a cable can significantly impact system performance, especially in low-voltage applications. Detailed calculations and mitigation strategies will be explained to help minimize losses.

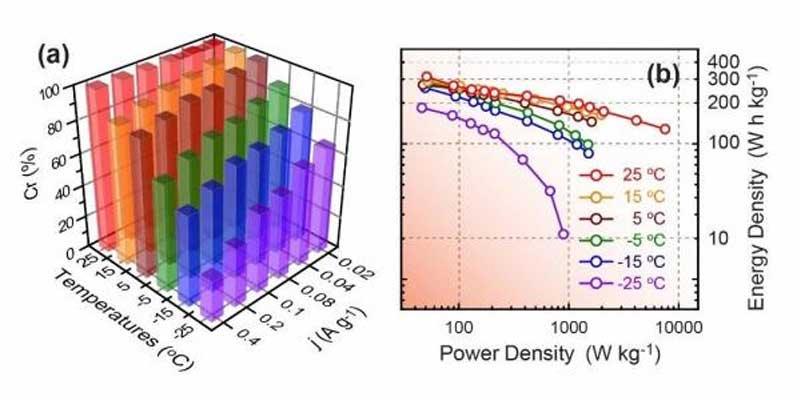

- Environmental Factors:

- Environmental considerations play a pivotal role in cable selection. This subsection will elaborate on choosing cable types based on environmental exposure, including chemical resistance, temperature tolerance, and mechanical durability.

Practical Case Studies

- Home Solar Energy Storage:

- A detailed case study will describe a real-world scenario of a home solar system, discussing how the proper cable selection improved efficiency and safety.

- Electric Vehicles:

- This case study will explore the critical role of high-quality cables in supporting the rapid charging and intense load demands of electric vehicles.

- Portable Power Stations:

- The unique challenges of portable power solutions, such as mobility and variable environmental conditions, will be discussed with examples of how specific cable choices can enhance operational reliability.

Conclusion The article will wrap up by summarizing the critical points about cable selection for lithium battery systems, reiterating the importance of meticulous planning and specification to enhance system performance and safety.

About Himax Electronics Finally, the article will conclude with a detailed segment about Himax Electronics, highlighting our expertise in providing robust battery solutions and tailored cable options that enhance both performance and safety across various applications.