In the ever-evolving world of healthcare technology, innovation isn’t just about precision — it’s about reliability, portability, and endurance. Shenzhen Himax Electronics Co., Ltd. (Himax), a leading manufacturer of custom lithium and NiMH battery packs, is once again making waves with its latest development: the 11.1V 2.6Ah lithium-ion battery pack designed specifically for medical display equipment. With a strong focus on safety, energy density, and customization, Himax is setting a new benchmark for powering critical healthcare systems where performance truly matters.

Powering Healthcare with Intelligence and Reliability

Modern medical devices — from portable monitors and handheld diagnostic tools to high-definition medical display screens — require compact, long-lasting, and stable power solutions. In these applications, even the smallest fluctuations in voltage or performance can have life-altering consequences. That’s where Himax’s 11.1V 2.6Ah Li-ion battery pack comes in.

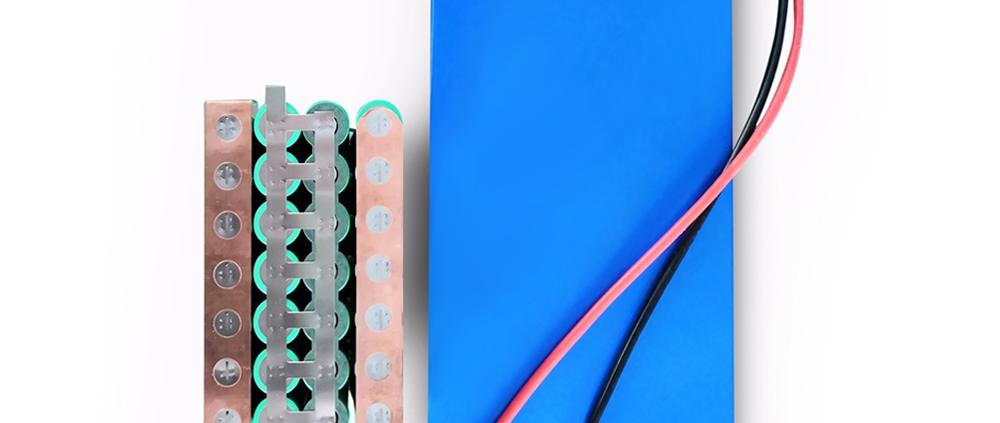

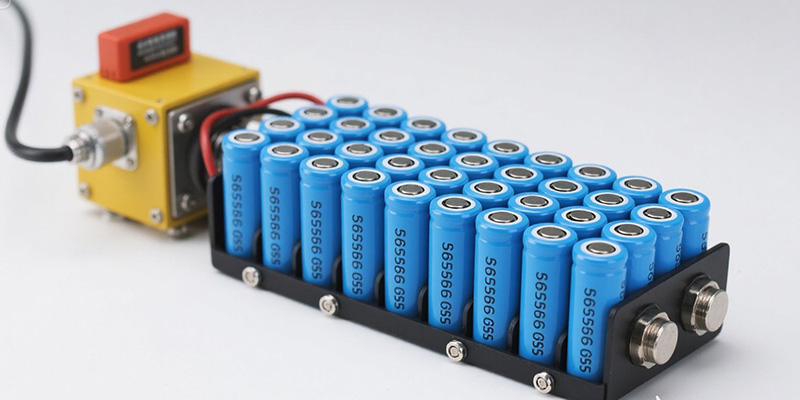

The battery pack is engineered using high-grade 18650 lithium-ion cells configured in a 3S1P arrangement, providing 11.1V nominal voltage and 2.6Ah capacity. This configuration ensures a steady and consistent power supply, ideal for sensitive medical imaging displays and mobile diagnostic devices that must function continuously and accurately.

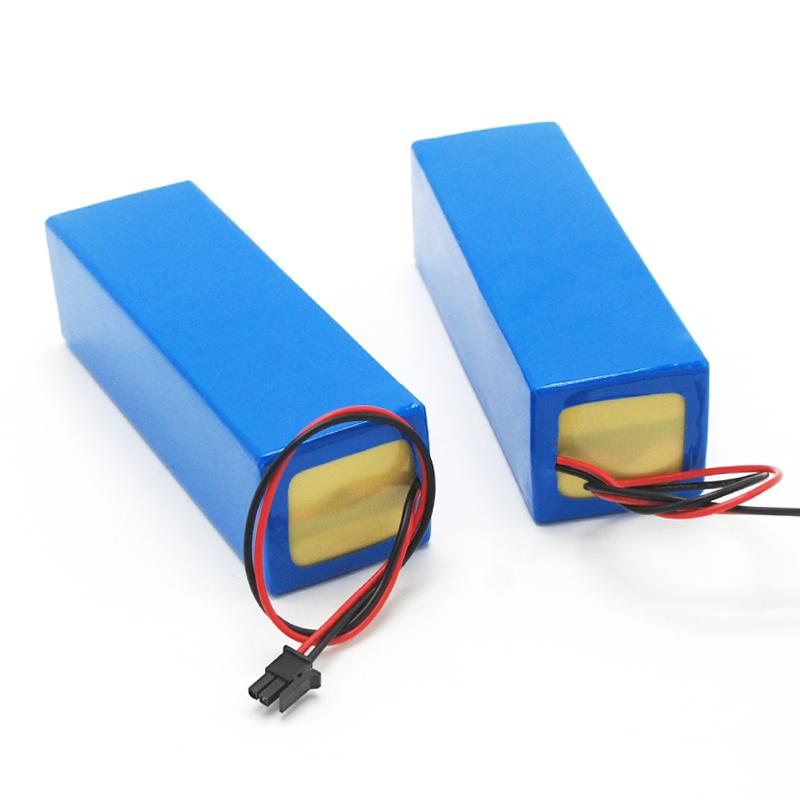

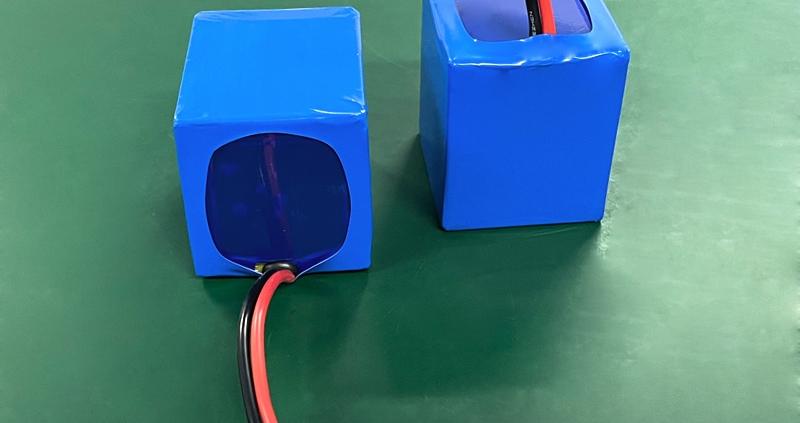

With a compact size, lightweight structure, and excellent energy efficiency, this battery pack meets the needs of manufacturers seeking balance between portability and performance. Whether used in medical tablets, patient monitoring screens, or portable ultrasound systems, the Himax battery pack guarantees smooth operation with dependable backup power — even in demanding medical environments.

Precision Engineering for Medical-Grade Performance

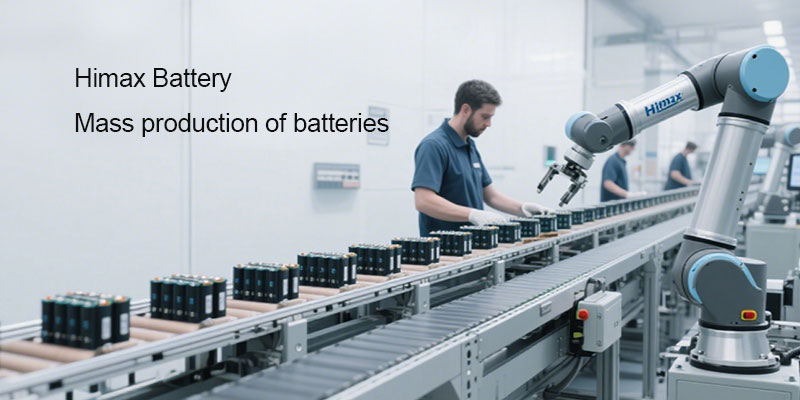

The 11.1V 2.6Ah Li-ion pack represents more than just an energy source; it’s the result of Himax’s continuous dedication to quality engineering and process excellence. Every pack is designed, assembled, and tested under ISO9001 and IEC62133 compliant facilities, ensuring full traceability and consistency across production batches.

1. Built for Safety and Stability

Safety is the cornerstone of any medical device. Himax’s battery pack incorporates multiple layers of protection circuits (PCM/BMS) that monitor voltage, current, and temperature in real time. These systems prevent overcharging, over-discharging, short circuits, and over-temperature conditions, significantly reducing risks during operation or long-term storage.

The battery’s low self-discharge rate and excellent cycle life make it especially suitable for medical devices that require both standby readiness and reliable daily performance. The inclusion of medical-grade connector options, such as Molex or JST interfaces, ensures seamless integration with medical display systems, providing plug-and-play convenience for manufacturers.

2. High Energy Density with Long Cycle Life

The 11.1V 2.6Ah pack delivers a high energy density that allows medical devices to operate longer between charges, supporting healthcare professionals in critical environments where uninterrupted power is essential. It maintains consistent performance even after 500+ charge cycles, retaining more than 80% of its original capacity, a key requirement for professional-grade medical electronics.

The use of premium lithium-ion cells ensures both high voltage stability and temperature resilience, enabling reliable operation under varying environmental conditions — from hospital wards to field diagnostics.

3. Compact Design, Custom Configurations

Himax understands that no two medical applications are the same. The 11.1V 2.6Ah pack can be customized in terms of shape, connector type, wire length, and mounting options, allowing it to fit precisely within the spatial constraints of each device. Engineers can also choose optional housing materials — such as flame-retardant ABS casings — to comply with medical device safety standards.

This flexibility has made Himax a trusted partner for OEM and ODM projects in the global medical technology market. Many clients across Europe, North America, and Australia rely on Himax’s ability to provide both small-batch prototypes and mass production with consistent quality assurance.

Meeting the Power Demands of Modern Medical Displays

Medical display systems are evolving rapidly. From surgical imaging monitors to portable diagnostic displays, these devices demand consistent, flicker-free power to maintain accurate color rendering, high brightness, and data precision. Himax’s 11.1V 2.6Ah lithium-ion battery addresses these demands by delivering stable voltage output throughout the discharge cycle, minimizing signal noise and display fluctuations.

This stability translates directly into improved image accuracy, data reliability, and longer uptime — essential for clinicians making real-time decisions based on visual data. The battery’s smart power management system also allows for efficient recharging cycles, reducing downtime and increasing operational efficiency in medical environments.

Furthermore, Himax provides optional features such as SMBus or I²C communication modules, enabling real-time battery status monitoring — including voltage, capacity, temperature, and cycle count. This capability supports predictive maintenance and enhances patient safety by preventing unexpected power loss during use.

Sustainability and Compliance

As global attention turns toward sustainability, medical device manufacturers face growing pressure to adopt environmentally responsible components. Himax’s lithium-ion battery packs are fully RoHS and REACH compliant, ensuring minimal environmental impact and adherence to international health and safety standards.

The company’s production lines feature both automated and semi-automated assembly systems, minimizing human error and ensuring consistent quality control. Himax’s in-house engineering team conducts rigorous testing for vibration, drop resistance, and thermal stability — guaranteeing each battery’s reliability before shipment.

By maintaining a dedicated warehouse in Melbourne, Australia, Himax also provides faster delivery and localized support for clients in the Oceania region, reducing lead times and improving supply chain resilience.

Global Expertise and Custom Solutions

With over a decade of experience in battery pack design and manufacturing, Himax continues to collaborate with medical technology innovators worldwide. The company’s expertise extends across Li-ion, LiFePO₄, and NiMH battery technologies, catering to diverse applications in healthcare, industrial automation, and smart mobility.

For clients requiring tailored solutions, Himax offers full engineering consultation, 3D battery modeling, and sample prototyping, ensuring that each design perfectly aligns with the performance, safety, and certification needs of its target device.

This customer-centric approach has earned Himax long-term partnerships with numerous well-known international companies, positioning it as a trusted energy solutions provider in the global medical technology supply chain.

A Vision for the Future

As healthcare continues its digital transformation, reliable portable power will remain the backbone of innovation. Medical devices are getting smaller, smarter, and more connected — and that evolution demands batteries that are equally advanced. Himax’s 11.1V 2.6Ah lithium-ion battery pack is not only meeting today’s technical standards but also anticipating tomorrow’s challenges.

From its design philosophy to its engineering precision, Himax remains committed to empowering healthcare technology through safer, smarter, and more efficient energy solutions. The company’s dedication to excellence ensures that hospitals, laboratories, and healthcare professionals around the world can rely on their devices — and the batteries within them — when every second counts.

About Himax

Shenzhen Himax Electronics Co., Ltd. is a professional manufacturer specializing in customized lithium-ion (Li-ion), lithium iron phosphate (LiFePO₄), and nickel-metal hydride (NiMH) battery packs. With automated production lines capable of processing 3 million cells per week and a team of experienced engineers, Himax delivers tailored power solutions for industries including medical, industrial, smart devices, and renewable energy.

With operations in China and Australia, Himax supports global clients through fast lead times, technical expertise, and flexible customization options — empowering innovation one battery pack at a time.