Introduction

In today’s rapidly advancing technological landscape, lithium batteries have become the cornerstone of energy storage solutions. From powering electric vehicles to running sophisticated electronic devices, their applications are vast and growing. For businesses looking to capitalize on this booming market, sourcing high-quality lithium batteries at wholesale prices is essential. However, with numerous manufacturers flooding the market, how do you choose the right one for your wholesale needs? This comprehensive guide will walk you through the critical factors to consider when selecting a lithium battery manufacturer, ensuring you make an informed decision that benefits your business in the long run.

Evaluate the Manufacturer’s Credentials and Experience

The first step in choosing the right manufacturer is to assess their credentials and industry experience.

Company Tenure and Industry Expertise

- Established Track Record: Look for manufacturers that have been in the industry for several years. A longer tenure often indicates stability and reliability.

- Technical Proficiency: Evaluate their expertise in lithium battery technology. Manufacturers specializing in lithium batteries are more likely to offer advanced and efficient products.

Research and Development

- Innovation Commitment: A manufacturer with a strong R&D department is more likely to produce cutting-edge batteries that meet the evolving demands of the market.

- Patents and Publications: Check if they hold any patents or have published research papers, which can be indicators of their innovation capabilities.

Quality Control and Certifications

Quality is non-negotiable when it comes to lithium batteries due to safety and performance considerations.

ISO and Other Quality Management Certifications

- ISO 9001 Certification: This certification indicates that the manufacturer adheres to international quality management standards.

- ISO 14001 Certification: Reflects their commitment to environmental management, which is crucial for sustainable business practices.

Quality Control Processes

- Rigorous Testing: Inquire about their quality control processes, including testing procedures for raw materials and finished products.

- Compliance with Standards: Ensure their products meet international standards such as UL, CE, and RoHS, which are critical for legal compliance and market acceptance.

Product Range and Customization Capabilities

Your business may have specific requirements that off-the-shelf products cannot meet.

Diverse Product Portfolio

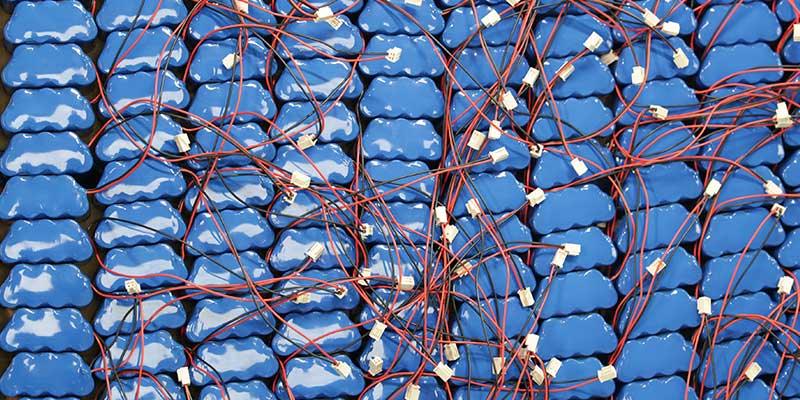

- Variety of Batteries: A manufacturer offering a wide range of lithium batteries—including Li-ion, LiPo, and LiFePO4—can cater to various applications.

- Different Specifications: Availability of batteries with varying capacities, voltages, and sizes provides more options for your business.

Custom Solutions

- Tailored Designs: If you need batteries designed to specific requirements, check if the manufacturer offers customization services.

- Flexibility in Orders: Manufacturers willing to accommodate custom orders, even in large quantities, can be invaluable partners.

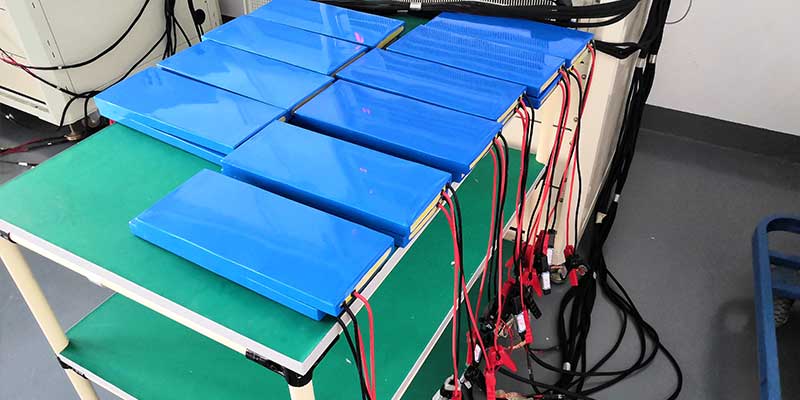

Production Capacity and Lead Times

Ensuring that the manufacturer can meet your demand without delays is crucial.

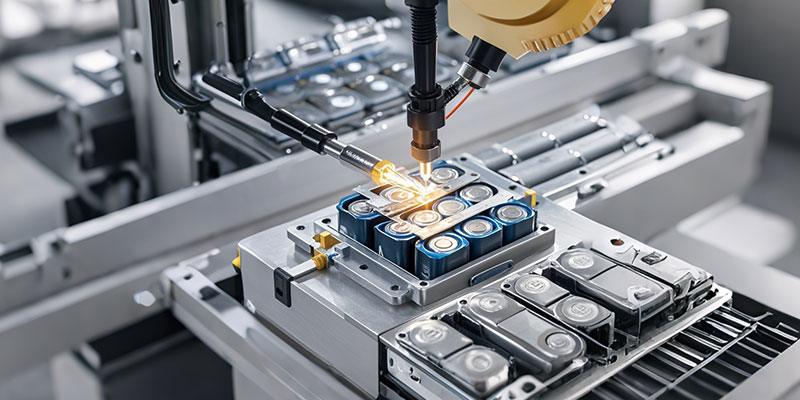

Manufacturing Scale and Equipment

- State-of-the-Art Facilities: Modern production lines equipped with advanced machinery can produce batteries more efficiently and with higher quality.

- Scalability: The ability to ramp up production to meet increasing demands ensures your supply chain remains uninterrupted.

Delivery Schedules

- Reliable Lead Times: Consistent and reasonable lead times are essential to maintain your business operations smoothly.

- Logistics Support: Manufacturers that offer robust logistics support can help in timely delivery and inventory management.

Technical Support and After-Sales Service

Ongoing support can significantly impact your experience with the manufacturer.

Expert Assistance

- Technical Guidance: Access to knowledgeable staff who can assist with product selection, integration, and troubleshooting is invaluable.

- Training Programs: Some manufacturers offer training for your staff, enhancing their understanding of the products.

After-Sales Policies

- Warranty Terms: Clear and fair warranty policies protect your investment.

- Responsive Customer Service: Quick response times for inquiries and issues demonstrate a manufacturer’s commitment to customer satisfaction.

Pricing and Cost-Effectiveness

While cost shouldn’t be the sole factor, it plays a significant role in your decision.

Competitive Pricing

- Transparent Pricing Models: Clear breakdowns of costs help you understand what you’re paying for.

- Bulk Discounts: Manufacturers offering significant discounts for large orders can improve your profit margins.

Total Cost of Ownership

- Long-Term Savings: Higher quality batteries may cost more upfront but offer better performance and longevity, reducing costs over time.

- Energy Efficiency: Batteries with higher efficiency can lower operational costs, adding to cost-effectiveness.

Customer Reviews and Reputation

A manufacturer’s reputation can provide insights into their reliability and product quality.

Testimonials and Case Studies

- Success Stories: Look for case studies or testimonials from businesses similar to yours.

- Diverse Clientele: Manufacturers serving a wide range of industries may have more robust capabilities.

Online Reviews and Ratings

- Third-Party Reviews: Check platforms like industry forums, LinkedIn, or review sites for unbiased opinions.

- Response to Criticism: How a manufacturer addresses negative feedback can indicate their commitment to customer satisfaction.

About Himax Electronics

Company Overview

Himax Electronics is a leading manufacturer specializing in high-quality lithium batteries. With over a decade of experience, we have established ourselves as a trusted partner for businesses worldwide.

Himax’s Advantages and Services

- Advanced Manufacturing: Our state-of-the-art facilities and cutting-edge technology ensure products of the highest quality.

- Customization Expertise: We offer tailored battery solutions to meet specific client needs, from design to production.

- Quality Assurance: Certified with ISO 9001 and ISO 14001, we adhere to strict quality and environmental management standards.

- Comprehensive Support: Our dedicated technical support team and responsive customer service ensure a seamless experience.

Why Choose Himax as Your Lithium Battery Manufacturer

- Reliability: Consistent product quality and dependable delivery schedules.

- Innovation: Commitment to research and development keeps us at the forefront of battery technology.

- Competitive Pricing: Transparent pricing models with attractive bulk discounts.

- Global Reach: Efficient logistics enable us to serve clients worldwide promptly.

Conclusion

Choosing the right lithium battery manufacturer for your wholesale needs is a critical decision that can significantly impact your business’s success. By carefully evaluating factors such as the manufacturer’s credentials, quality control measures, product range, production capacity, support services, pricing, and reputation, you can identify a partner that aligns with your business objectives.

Himax Electronics embodies all these qualities, making us an ideal choice for your lithium battery requirements. Our unwavering commitment to quality, innovation, and customer satisfaction positions us as a leader in the industry.

Take the next step towards securing a reliable supply of high-quality lithium batteries for your business. Contact Himax Electronics today to discuss how we can meet your wholesale needs and contribute to your success.