What should I do if 12V LiFePO4 batteries connected in parallel cannot be charged?

Introduction

In the landscape of modern energy solutions, Lithium Iron Phosphate (LiFePO4) batteries are highly favored for their exceptional performance and longevity. These batteries are widely used in a range of applications, from electric vehicles to renewable energy storage. Parallel connection of batteries is a common practice that enhances total current output and battery capacity to meet higher energy demands. However, in practical operations, issues such as the inability to charge can arise when multiple 12V LiFePO4 batteries are connected in parallel. Not only does this affect the normal operation of equipment, but it can also shorten the lifespan of the batteries. Facing such challenges, understanding the causes and solutions becomes crucial. Through an in-depth analysis and recommendations provided in this article, users can gain the necessary knowledge to optimize their battery usage, ensuring efficient and reliable operation of their energy systems.

Common Reasons for Charging Failures in Parallel LiFePO4 Batteries

Mismatched Batteries: When connecting batteries in parallel, it is essential that all batteries share the same voltage, capacity, and brand. Mismatches, such as different manufacturing dates or charging cycles, can lead to imbalances in voltage and capacity. This imbalance can cause some batteries to overcharge while others remain undercharged, leading to decreased performance or even damage.

Connection Errors: Proper wiring and connection methods are crucial for parallel battery setups. If the wiring is incorrect or if there are loose or corroded contact points, the current may not flow evenly through all batteries, thereby affecting the overall charging efficiency of the system. Additionally, incorrect wiring can lead to short circuits, increasing the risk of safety hazards.

Charger Issues: The charger used for a parallel battery system must match the specifications of the batteries. Using an incompatible charger, such as one with an unsuitable voltage or current output, can prevent effective charging of the battery group. Furthermore, malfunctions within the charger itself can also cause charging issues.

Battery Aging or Damage: Even high-quality LiFePO4 batteries will degrade over time and with increased usage. Aging typically manifests as a decline in capacity and an increase in internal resistance, reducing charging and discharging efficiency. In a battery group, the performance decline of even a single battery can significantly impact the overall group performance, especially in a parallel configuration.

Solutions and Troubleshooting Steps

Check Battery and Charger Compatibility: First, ensure that all batteries and the charger used are fully compatible with the specifications. Check that the charger’s output voltage and current are suitable for the parallel battery group. Additionally, ensure all batteries are from the same brand, model, capacity, and voltage to prevent performance discrepancies among them.

Inspect and Reconnect Batteries: Disconnect the battery group and individually check the condition of each battery. Use voltmeters and resistance meters to measure the voltage and internal resistance of each battery unit to identify any significant performance decline or damage. Ensure that all connections are clean, tight, and free from corrosion or looseness.

Use Professional Diagnostic Equipment: Where possible, use professional battery testing equipment to conduct a thorough inspection and diagnosis of the entire battery group. These devices can accurately measure the charging state, capacity, and health of the batteries, aiding in the identification and isolation of problematic batteries.

Consider Replacing or Repairing Batteries: If a battery’s performance has indeed significantly declined, it is advisable to replace it to ensure the performance and safety of the entire battery group. For minor repairable issues, such as poor contact or slight corrosion, timely maintenance and cleaning should be carried out.

Seek Professional Help: In complex situations where self-diagnosis and repair are challenging, it is recommended to contact professional battery repair services. Experienced technicians have the tools and expertise to handle advanced battery system issues and can provide more effective solutions.

Preventative Measures and Best Practices

Choose High-Quality Batteries and Compatible Chargers: Selecting high-quality LiFePO4 batteries and compatible chargers is the first step in preventing charging issues. Quality batteries provide more stable performance and extend the system’s lifespan. Ensuring that the charger’s specifications fully match the battery group is crucial for maintaining the health of the battery group.

Regular Maintenance and Inspection: Regularly perform visual inspections and performance tests on the battery group to ensure all batteries are in good condition. Check that all connection points are tight and free from corrosion, and inspect batteries for swelling, leakage, or other visible signs of damage. These simple checks can help detect issues early and prevent minor problems from becoming major ones.

Proper Battery Storage: Store batteries in a dry, cool place, away from extreme temperatures or humidity. Improper storage conditions can accelerate battery aging, reducing performance and lifespan.

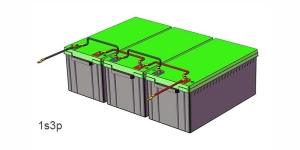

Use a Battery Management System (BMS): Equipping the battery group with an efficient Battery Management System can effectively monitor and regulate the charging state and health of the batteries. A BMS can prevent overcharging, over-discharging, and battery imbalance issues, thereby enhancing the efficiency and safety of the entire battery group.

Education and Training: Provide appropriate training for personnel who operate and maintain the battery systems. Understanding how to properly handle batteries and address common battery issues is key to ensuring the safe operation of the equipment.

Case Studies

In this section, we will share several case studies about successfully resolving charging issues with parallel LiFePO4 batteries. These cases will highlight the identification, analysis, and resolution of specific problems.

Case Study 1: Mismatched Batteries Leading to Charging Failures

-

Background: An electric bicycle manufacturing company used parallel 12V LiFePO4 battery packs in their products. They noticed that the charging time for some electric bicycles was much longer than expected.

-

Diagnosis: Upon detailed inspection, the technical team discovered that several batteries within the parallel groups were from different production batches, leading to significant performance variations.

-

Solution: All mismatched batteries were replaced with ones from the same production batch. Additionally, preliminary checks on battery batches and performance were implemented to prevent similar issues in the future.

-

Result: After replacing the batteries, the charging times for all electric bicycles returned to normal, significantly improving customer satisfaction.

Case Study 2: Incorrect Connections and Charger Issues

-

Background: A solar energy storage provider frequently encountered insufficient charging issues in multiple battery systems installed at a client’s site.

-

Diagnosis: Inspections revealed that some battery connections used low-quality wiring, and some chargers did not match the specifications required by the battery group.

-

Solution: All low-quality connection materials were replaced, and appropriate chargers that fully met the needs of the battery group were installed.

-

Result: After the replacements, the system’s stability and charging efficiency significantly improved, reducing maintenance costs and customer complaints.

Introduction to Himax Electronics

Himax Electronics is a leading enterprise dedicated to providing high-performance battery solutions for a wide range of industrial and commercial applications. As pioneers in Lithium Iron Phosphate (LiFePO4) battery technology, our products are renowned for their high energy efficiency, long lifespan, and outstanding safety features.

Products and Services

-

We offer an extensive range of LiFePO4 battery products, including standard battery packs and customized solutions to meet diverse market needs.

-

Our battery solutions are widely used in electric transportation vehicles, renewable energy storage systems, emergency backup power, and other applications requiring reliable power sources.

Quality Commitment and Innovation

-

At Himax Electronics, quality is our core commitment. We adhere to strict international standards, performing comprehensive quality control and performance tests on each batch of batteries produced.

-

Innovation drives our progress. Our research and development team continuously explores new technologies to enhance battery performance and efficiency while reducing environmental impact.

Customer Service and Support

-

We understand that each customer’s needs are unique, thus we offer customized customer service and technical support to ensure that clients receive the best-suited battery solutions for their applications.

-

Our technical support team is equipped with extensive expertise and is always ready to assist customers with installation, maintenance, or troubleshooting issues.

We invite you to visit our website for more information or to contact our professional team directly for more detailed information about Himax Electronics products and services. No matter what your project requirements are, Himax Electronics is your trustworthy partner.