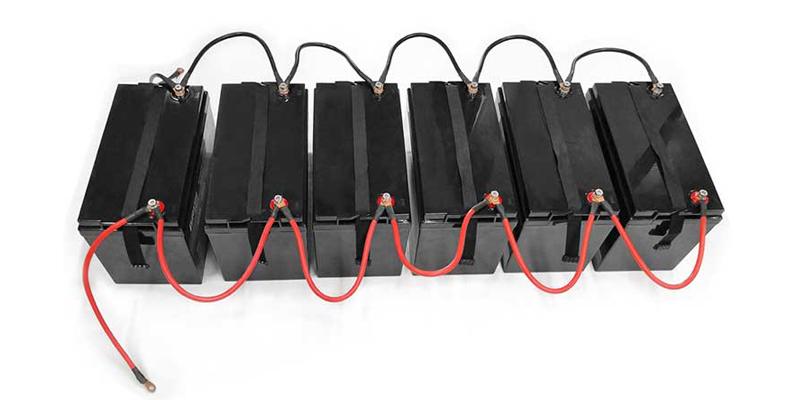

Battery Pack Cell Voltage Difference And Solution Part 2

We have introduced voltage difference in battery packs and used it as an important criterion for measuring the quality of batteries. At this time, we’ll review how to prevent voltage difference.

Match the cells

The best method in preventing cell voltage difference is to match the cells before the battery pack is assembled and to select the cells with the closest consistency for assembly. To put it simply, you match the batteries with the most similar specifications according to the configuration of the battery pack. There are many ways you can match the cells, but the most important elements to consider are the capacity, internal resistance, and voltage difference.

Ensure the quality

In Grepow, in addition to the conventional matching standards, we match the content of the battery cell’s production batches, material batches and other standards to ensure that the quality of the battery packs we produce is the best. If the matching standard is stricter, then the probability of the battery cell voltage difference will be smaller. On the contrary, if the battery cell matching standard is less strict or if there is no matching at all, the probability of the cell voltage difference will be greater, and this will result in premature battery failure.

Use the BMS

In addition to the matching of cells before assembly, the use of a BMS balancing circuit is another great way to prevent voltage differences. At present, most BMSs on the market have charging balancing circuits. The function of the balancing circuit is to equalize the voltage of each cell during the battery charging process and to keep the voltage of the cell as consistent as possible. If you are using a BMS to prevent voltage difference, ensure that the one you are using or selecting has the balancing feature.

Others

There are other possibilities that may also cause a voltage difference, such as cell damages and high-temperature storage.