What is a forklift battery?

A forklift battery actually has two functions:

- To provide a power source to the forklift.

- The lesser-known function is to provide mass as a counterweight, which aids the forklift’s lifting capacity.

The most common forklift batteries are Lead Acid, but a trend to use Lithium iron phosphate replacement battery due to advantages of higher capacity, safety, and more cycles, etc.

However, we found that there are more forklift customers are require LiFePo4 battery and a few low-temperature requirement. For a simple comparison:

- Price

Lead-Acid battery: $$$

LiFePO4 battery: $$$$$$$$$$

- Features

LiFePO4 battery > Lead Acid battery

Let’s take an example if the working environment is the low temperature like freezer inventory, so Lithium iron phosphate must be better due to working at low temperatures for a long time, and low-temperature charging required.

- Weight

Lead-Acid battery: More Heavy (70kg and 80kg per kWh of usable capacity)

LiFePO4 battery: Lighter (10kg and 15kg per kWh of usable capacity)

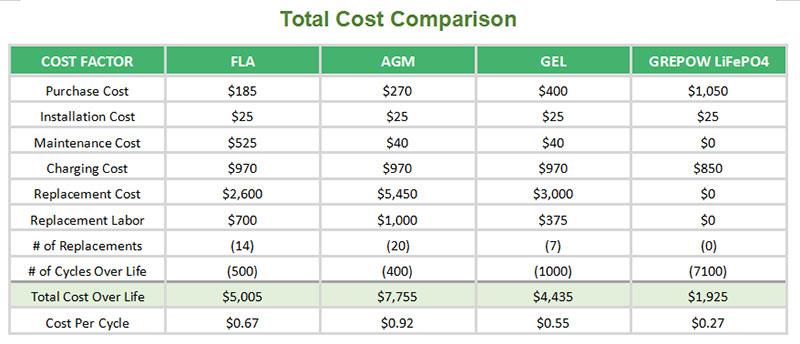

- Cost per cycle

LiFePO4 battery (more charge & discharge cycles) > Lead Acid battery

The cycles count of traditional Lead-acid battery is around 500–600 times, LiFePO4 battery is around 2000 times (The promise cycles of Grepow Lithium iron phosphate battery is 1500 times / 3 years)

In addition to the high initial cost of Lithium iron phosphate battery, it is free of replacement and maintenance cost, that’s why LiFePO4 battery is more economical than Lead Acid even higher initial cost.