The Difference Between Steel-shell, Aluminum-shell And Pouch-cell Batteries

The shell materials used in lithium batteries on the market can be roughly divided into three types: steel shell, aluminum shell and pouch cell (i.e. aluminum plastic film, soft pack). We will explore the characteristics, applications and differences between them in this article.

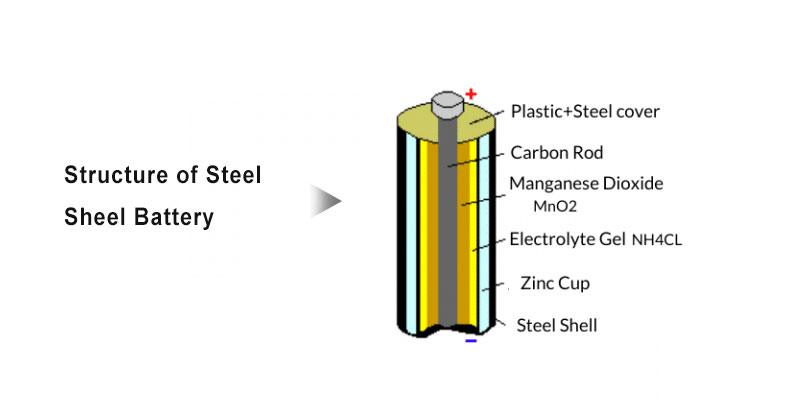

Steel–Shell Battery

The steel material for this battery is physically stable with its stress resistance higher than aluminum shell material. It is mostly used as the shell material of cylindrical lithium batteries.

In order to prevent oxidation of the steel battery’s positive electrode active material, manufacturers usually use nickel plating to protect the iron matrix of the steel shell and place a safety device inside the battery cell.

At present, most laptops use steel-shell batteries, but it is also used in toy models and power tools.

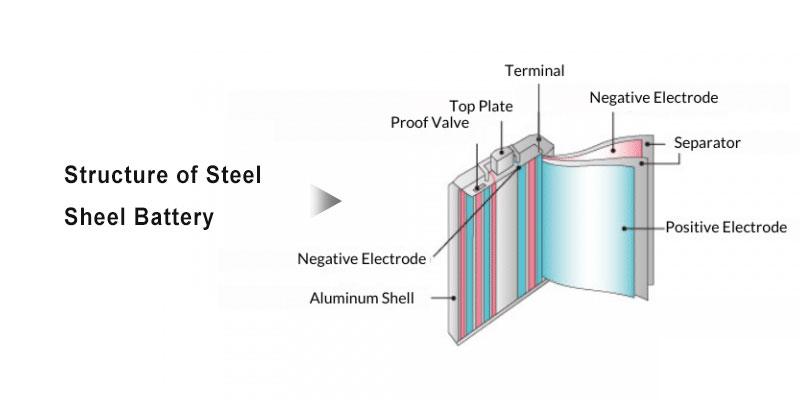

Aluminum–Shell Battery

The aluminum shell is a battery shell made of aluminum alloy material. It is mainly used in square lithium batteries. They are environmentally friendly and lighter than steel while having strong plasticity and stable chemical properties.

Generally, the material of the aluminum shell is aluminum-manganese alloy, and its main alloy components are Mn, Cu, Mg, Si, and Fe. These five alloys play different roles in the aluminum shell battery. For example, Cu and Mg improve strength and hardness, Mn improves corrosion resistance, Si can enhance the heat treatment effect of magnesium-containing aluminum alloys, and Fe can improve high temperature strength.

Aluminum shell batteries are the main shell material of liquid lithium batteries, which is used in almost all areas involved.

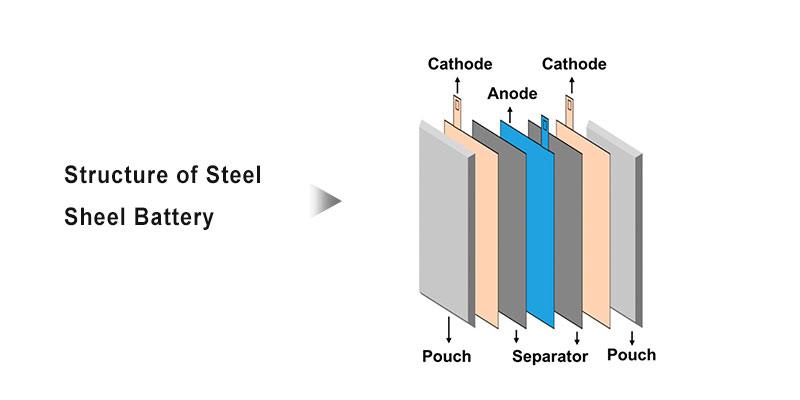

Pouch–Cell Battery

The pouch-cell battery (soft pack battery) is a liquid lithium-ion battery covered with a polymer shell. The biggest difference from other batteries is its packaging material, aluminum plastic film, which is also the most important and technically difficult material in pouch cells.

The packaging materials are usually divided into three layers: the outer barrier layer (it is usually an outer protective layer composed of nylon BOPA or PET), barrier layer (middle layer aluminum foil) and inner layer (multifunctional high barrier layer). The materials such as positive electrode, negative electrode, electrolyte, separator and so on are similar to other types of batteries.

The hidden danger of lithium batteries is the instability of the material or other unexpected comprehensive factors, which may cause the heat to run out of control and result in gas accumulation in the battery. This is dangerous because steel-shell and aluminum-shell batteries have a fixed space. When the gas inside these batteries expands beyond the limits of this space, the battery will explode. Pouch cells will also bulge up and crack, so they have a higher safety index.

Compared with steel and aluminum batteries (i.e. hard-shell batteries), pouch-cell batteries can have a flexible design, low internal resistance, more cycle time, and high energy density. They are lightweight, and they do not explode easily.

Pouch-cell batteries are 40% lighter than steel-shell lithium batteries of the same capacity and 20% lighter than aluminum-shell batteries. The capacity can be 10-15% higher than steel-shell batteries of the same size and 5-10% higher than aluminum-shell batteries of the same size.

In light of the advantages of pouch-cell batteries, industry experts predict that pouch-cell batteries will have a higher chance of penetrating the new energy vehicle market with more development. In the future, pouch-cell batteries are expected to account for more than 50% of all types of batteries.

In addition to being used as power batteries and energy storage batteries, pouch-cell batteries are also used as battery components for 3C electronic products, such as mobile phones, drones, wearable devices, RCs, etc.