In today’s battery technology landscape, lithium-ion batteries (NMC/NCA) and lithium iron phosphate (LiFePO4 or LFP) batteries are the two dominant chemistries. Together, they power the global transition to clean energy—supporting applications ranging from electric vehicles and consumer electronics to home energy storage and telecom backup systems.

Although both belong to the lithium family, their chemical structures lead to very different performance characteristics. Understanding these differences is essential for engineers, system integrators, and buyers who want to choose the most suitable battery solution for their application.

This article provides a clear, practical comparison to help you make an informed decision.

1. Chemical Fundamentals: Where the Differences Begin

The most fundamental difference between lithium-ion and LiFePO4 batteries lies in the cathode material, which directly determines energy density, safety, lifespan, and cost.

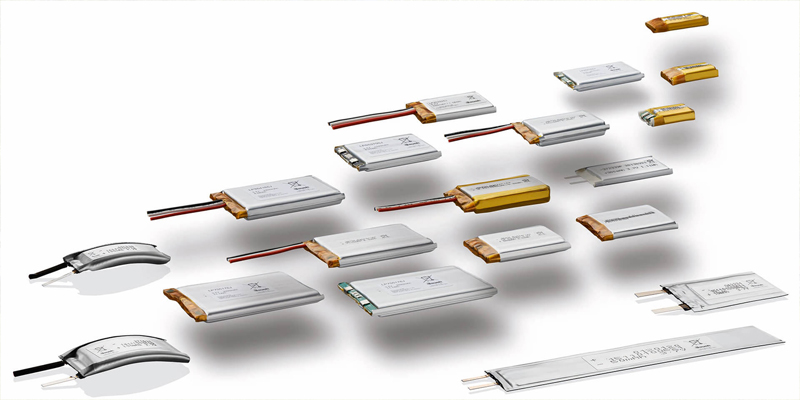

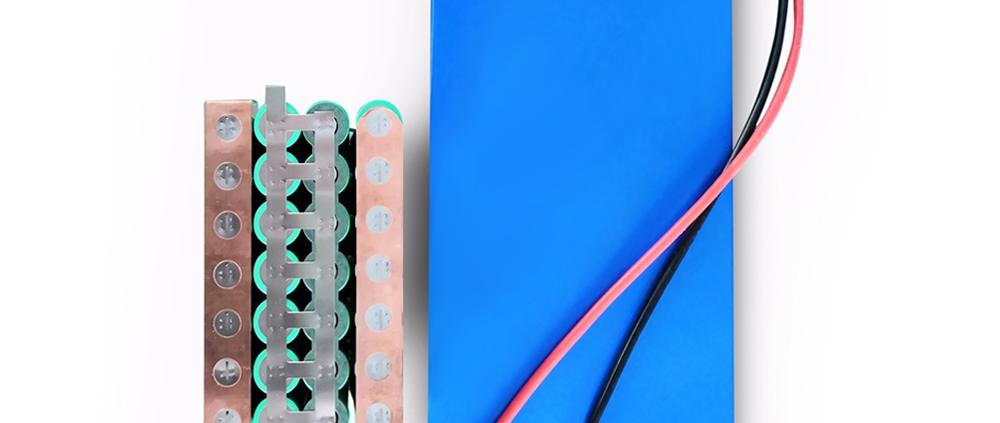

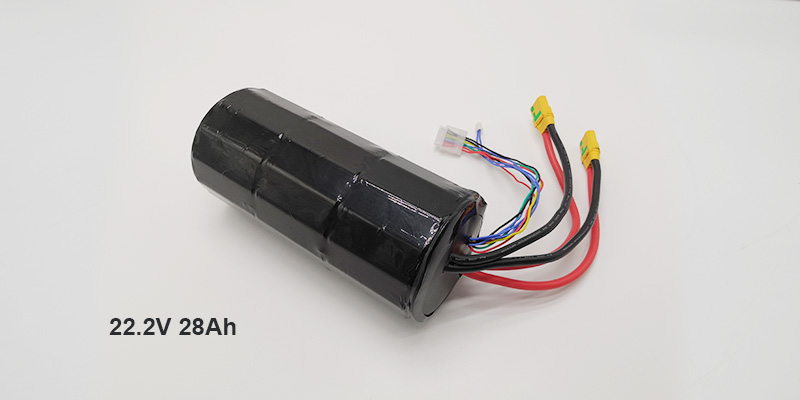

Lithium-ion Batteries (NMC / NCA)

Lithium-ion batteries use lithium nickel manganese cobalt oxide (NMC) or lithium nickel cobalt aluminum oxide (NCA) as the cathode material.

Thanks to their high operating voltage and layered crystal structure, these batteries can store more energy in a smaller and lighter package.

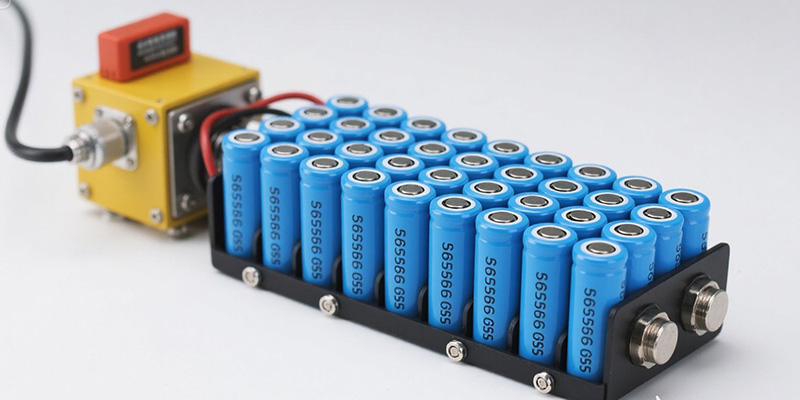

LiFePO4 Batteries (LFP)

LiFePO4 batteries use lithium iron phosphate as the cathode.

Their stable olivine crystal structure provides excellent thermal stability and strong resistance to degradation, which is the foundation of their long cycle life and high safety level.

2. Five Key Performance Dimensions Compared

Below is a simplified comparison across five critical performance areas that matter most in real-world applications.

1) Energy Density

Lithium-ion: High (200–300 Wh/kg)

LiFePO4: Medium (140–180 Wh/kg)

Selection insight:

If your product requires lightweight design or long runtime—such as electric vehicles, drones, or portable electronics—lithium-ion batteries are usually the better choice.

If size and weight are less critical, LiFePO4 is often preferred for its other advantages.

2) Safety

Lithium-ion: Medium

LiFePO4: High

LiFePO4 batteries have excellent thermal stability and are much less prone to thermal runaway, even under conditions such as overcharging, short circuit, or mechanical damage.

For applications where safety is the top priority, LiFePO4 is widely regarded as an inherently safer chemistry.

3) Cycle Life

Lithium-ion: 500–1,000 cycles

LiFePO4: 2,000–5,000 cycles (or more)

Selection insight:

For applications sensitive to total lifetime cost—such as energy storage systems, commercial vehicles, or backup power—LiFePO4’s long cycle life provides a clear advantage.

4) Cost

Lithium-ion: Higher (contains cobalt and nickel)

LiFePO4: Lower (iron and phosphate are abundant)

Raw material cost and price volatility make lithium-ion batteries more expensive.

LiFePO4 batteries benefit from lower and more stable material costs, which is a key reason for their rapid adoption in large-scale commercial and energy storage projects.

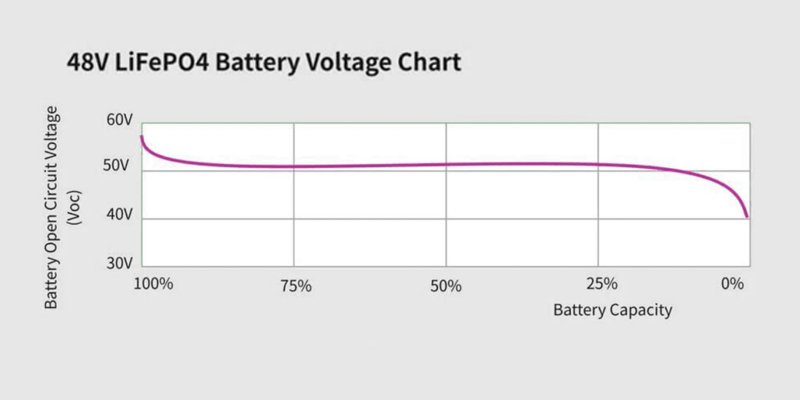

5) Low-Temperature Performance

Lithium-ion: Better

About 70% capacity retention at –20°C

LiFePO4: Weaker

About 50–60% capacity retention at –20°C

Selection insight:

For cold climates or outdoor applications, lithium-ion batteries perform better.

LiFePO4 systems can still be used in cold environments, but they often require heating elements or advanced thermal management.

3. Strengths and Challenges in Detail

Advantages and Challenges of Lithium-ion Batteries

Key advantages:

High energy density enables longer driving range or smaller battery packs

Supports fast charging and high power output

Ideal for performance-focused applications

Main challenges:

More sensitive to overcharging and high temperatures

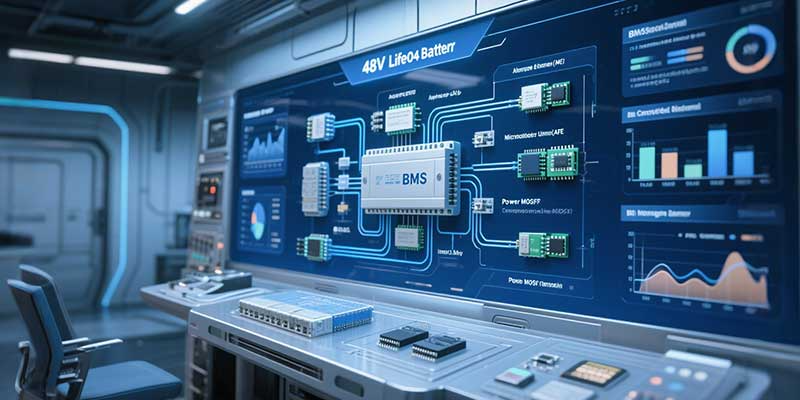

Requires a precise and reliable battery management system (BMS)

Shorter cycle life compared to LiFePO4

Higher and less stable raw material costs

Advantages and Limitations of LiFePO4 Batteries

Key advantages:

Outstanding safety and thermal stability

Very long cycle life, reducing cost per kWh over time

No cobalt or nickel, making it more environmentally friendly

Stable performance over many years of use

Main limitations:

Lower energy density

Larger and heavier packs for the same capacity

Reduced performance in low-temperature environments

4. Application Scenarios: Which Battery Should You Choose?

Choose Lithium-ion If Your Priority Is:

Maximum energy density

Long-range electric vehicles

Drones and aviation-related systems

High-end consumer electronics

High power output

Power tools

Performance hybrid or electric vehicles

Cold climate operation

Outdoor or automotive applications in low temperatures

Choose LiFePO4 If Your Priority Is:

Safety and long-term reliability

Energy storage systems (ESS)

Solar storage

Telecom base station backup power

Lower total cost of ownership

Commercial EVs

Electric buses and logistics vehicles

Shared mobility fleets

Fixed installations with high safety requirements

Home energy storage

Security and monitoring equipment

Marine and UPS backup systems

5. Future Trends: Competition or Coexistence?

The market is not moving toward a “winner-takes-all” solution. Instead, it is evolving toward application-based optimization.

Technology Evolution

Lithium-ion batteries are shifting toward high-nickel, low-cobalt formulations to increase energy density while reducing cost.

LiFeO4 batteries are improving pack-level efficiency through innovations such as CTP (Cell-to-Pack) and blade battery designs, which significantly increase volumetric energy density.

Mixed Battery Strategies

Some automakers now adopt dual chemistry strategies:

Entry-level models use LiFePO4 for cost and safety

Premium models use lithium-ion for performance and range

System-Level Optimization

Regardless of chemistry, system design is critical.

Battery performance and safety heavily depend on:

Battery management system (BMS)

Thermal management design

Manufacturing quality and consistency

In many cases, a well-designed LiFePO4 system can outperform a poorly designed lithium-ion system—and vice versa.

Conclusion: There Is No Perfect Battery, Only the Right One

The choice between lithium-ion and LiFePO4 batteries is ultimately a strategic trade-off between energy density and safety/longevity.

If every gram and every kilometer matters, lithium-ion is often the right answer.

If long term stability, safety, and life cycle cost are more important, LiFePO4 is the smarter choice.

There is no universal “best battery”—only the most suitable solution for a specific application.

When selecting a battery, always return to the core question:

Do you need maximum performance today, or stable and reliable operation for the next ten years?

The answer will guide you to the right technology.