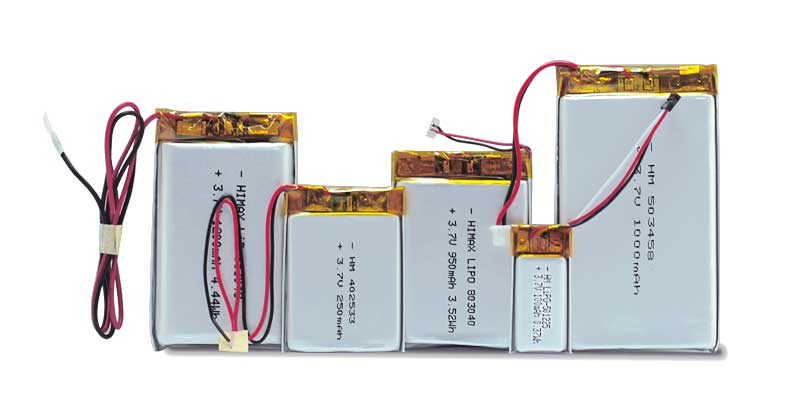

The popularity of drones has soared in recent years, with applications spanning from professional aerial photography to recreational flying for hobbyists and children. Among these categories, toy drones have gained significant traction for their affordability, accessibility, and fun. Behind their smooth take-offs, stable flights, and responsive controls lies a critical component: the battery. Himax, a global leader in lithium battery solutions, has recently highlighted the importance of its 3.7V 1500mAh LiPo (Lithium Polymer) battery, designed specifically for toy drones. This battery has emerged as a vital enabler of longer flights, safer operation, and a more enjoyable user experience.

This article explores how the 3.7V 1500mAh LiPo battery works, why it stands out in the toy drone industry, and what makes Himax’s solution a benchmark for manufacturers and consumers alike.

Why Power is the Core of Toy Drone Performance

Toy drones are lightweight, affordable, and designed for indoor or light outdoor use. However, their performance depends heavily on the power system. Without a reliable battery, even the best-designed toy drone cannot achieve stable flight. The requirements of toy drones are unique:

- Lightweight Power Source– Any excess weight reduces lift and flight time.

- Safe Operation– Since drones are used by children and beginners, safety features like overcharge protection are critical.

- Longer Flight Time– Short play sessions frustrate users. Extending flight from a few minutes to 15 minutes or more creates a significant improvement.

This is where the 3.7V 1500mAh LiPo battery comes into play. It balances size, capacity, and safety, providing an optimal power solution for drones under 250 grams.

How the 3.7V 1500mAh LiPo Battery Works

The battery’s engineering highlights why it has become a preferred choice for toy drones.

- Voltage and Cell Configuration

A single LiPo cell provides a nominal voltage of 3.7V.

This voltage aligns perfectly with the small brushless or brushed motors typically used in toy drones, delivering consistent power without stressing the system.

2.Capacity of 1500mAh

The 1500mAh capacity translates to longer flight sessions compared to smaller 800mAh or 1000mAh batteries.

Depending on drone design and weight, users can expect between 10–18 minutes of flight time, a considerable improvement in toy drone performance.

3.Discharge Rate

LiPo batteries are known for their ability to provide high burst currents.

The 3.7V 1500mAh pack supports sufficient discharge rates to handle quick accelerations, flips, and maneuvers without voltage drops.

4.Rechargeability

With proper care, the battery can withstand hundreds of charging cycles, reducing cost for parents and hobbyists.

5.Safety Features

Himax integrates overcharge, over-discharge, and short-circuit protections to safeguard both the drone and the user.

Why LiPo Outperforms Other Battery Types

Toy drones once relied on NiMH or alkaline batteries. However, these older technologies come with significant limitations:

Lower Energy Density: Heavier batteries for the same capacity, reducing drone efficiency.

Slower Discharge: Poor performance in fast maneuvers.

Short Lifespan: Fewer charging cycles compared to LiPo.

By contrast, the 3.7V 1500mAh LiPo battery provides:

Higher energy density – More power in a compact size.

Lightweight construction – Essential for flight performance.

Stable discharge curve – Ensures consistent flight power.

Extended cycle life – Offering better long-term value.

Himax’s Edge in the Market

Not all LiPo batteries are created equal. Himax ensures its 3.7V 1500mAh pack meets strict international standards. Its advantages include:

Customization for Toy Manufacturers

Himax offers tailored solutions, adjusting battery size, connectors, and casings to fit specific drone models.

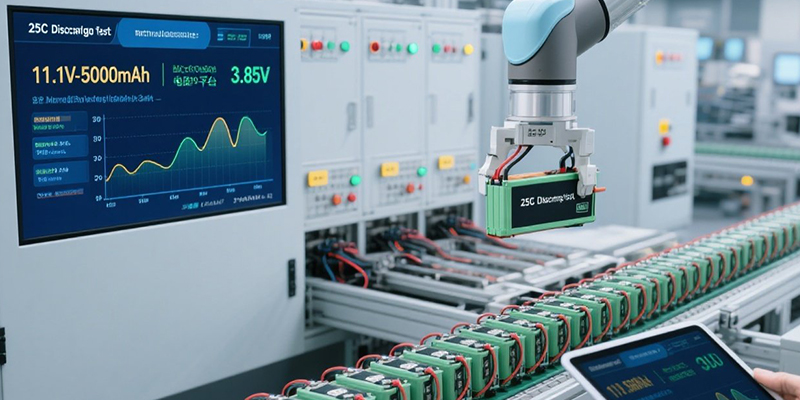

Quality Assurance

Each battery undergoes rigorous testing for capacity, cycle life, and safety to ensure consistent performance.

Global Supply Chain

With warehouses in Asia, Europe, and Australia, Himax ensures faster delivery and localized support.

Focus on Sustainability

Himax emphasizes eco-friendly production processes and designs batteries with recyclable materials wherever possible.

Applications Beyond Toy Drones

While optimized for toy drones, the 3.7V 1500mAh LiPo battery also powers other compact devices:

Mini RC cars and boats.

Handheld gaming gadgets.

Educational robots in STEM kits.

Portable LED lights or small appliances.

This versatility broadens its market potential, making it a valuable option for various consumer electronics.

Market Trends and Consumer Expectations

The toy drone market is expected to expand rapidly, especially with the rising popularity of STEM toys and the increased affordability of drone technology. Parents and hobbyists are demanding longer runtimes, faster charging, and safer batteries.

Consumer feedback on Himax’s 3.7V 1500mAh LiPo battery highlights:

Longer playtime before recharging.

Consistent power for stable flights.

Enhanced safety compared to low-quality alternatives.

This aligns with broader industry trends where consumers prioritize performance and reliability over the lowest price.

Challenges and Future Directions

Despite its benefits, LiPo technology requires careful handling. Overcharging or puncturing can cause safety risks. Himax addresses these concerns through built-in protection systems and improved casing designs.

Looking ahead, the company is exploring:

Higher capacities in compact formats.

Fast-charging solutions to reduce downtime.

Smart batteries with monitoring apps, allowing users to check charge levels on their phones.

These innovations will further enhance the role of LiPo batteries in the toy drone sector.

Conclusion

In summary, the 3.7V 1500mAh LiPo battery is a game-changer for toy drones, delivering the ideal balance of power, weight, and safety. It provides longer runtimes, stable discharge, and eco-friendly rechargeability, setting a new standard for recreational drone users. Beyond drones, its versatility ensures broad applicability in other lightweight electronics.

Himax, with its expertise in custom lithium and NiMH battery solutions, continues to lead this transformation. By combining cutting-edge technology, global supply networks, and a commitment to sustainability, Himax reaffirms its role as a trusted partner in powering the future of toys and consumer electronics.