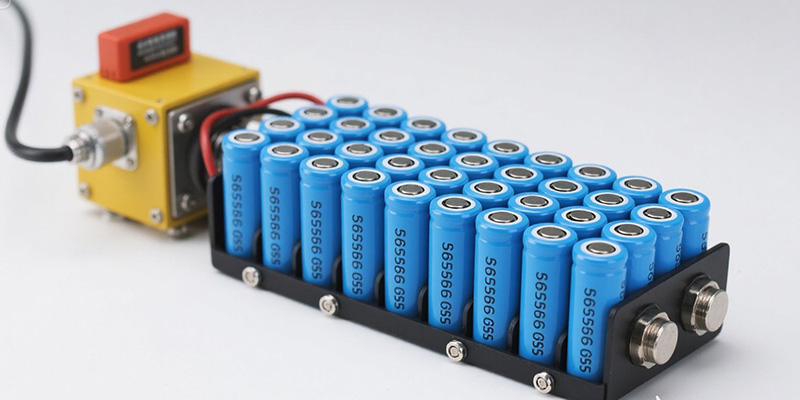

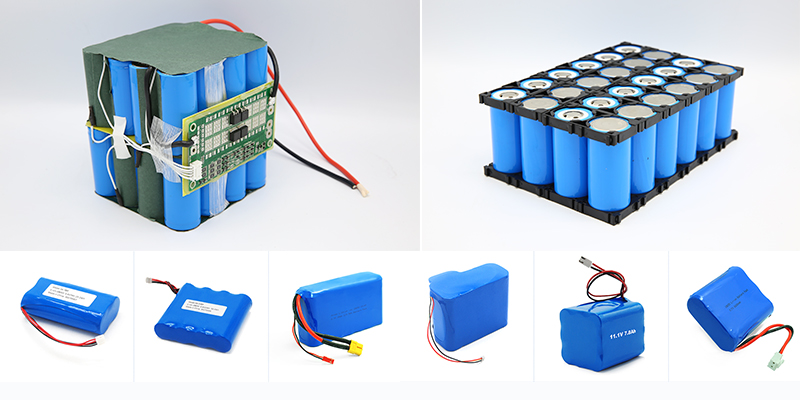

Lithium-ion batteries are widely used today in robotics, electric tools, solar energy systems, and countless portable devices. They are known for their high energy density, long cycle life, and stable performance. However, proper storage is essential to keep these batteries healthy and to prevent capacity loss or safety issues over time.

At Shenzhen Himax Electronics Co., Ltd., we often remind customers that even the most advanced lithium battery can deteriorate quickly if it is not stored under the right conditions. Knowing how to store your battery correctly ensures longer lifespan, reliable performance, and maximum safety.

Why Proper Storage Matters

When a lithium battery is not in use, chemical reactions inside the cells still continue slowly. These reactions cause self-discharge, capacity fade, and voltage imbalance over time.

Poor storage conditions — such as high temperature, high humidity, or deep discharge — can significantly accelerate these effects.

By storing your lithium battery properly, you can:

- Prevent over-discharge and cell damage

- Maintain voltage balance among cells

- Slow down natural aging

- Keep the pack ready for safe use anytime

The Ideal State of Charge (SOC) for Storage

One of the most common mistakes is storing batteries either fully charged or completely empty.

The ideal storage state of charge for most lithium-ion batteries is between 50% and 60%.

If stored fully charged (100%): The high voltage accelerates electrolyte oxidation and capacity loss.

If stored fully discharged (0%): The voltage may drop too low, leading to irreversible chemical damage and over-discharge.

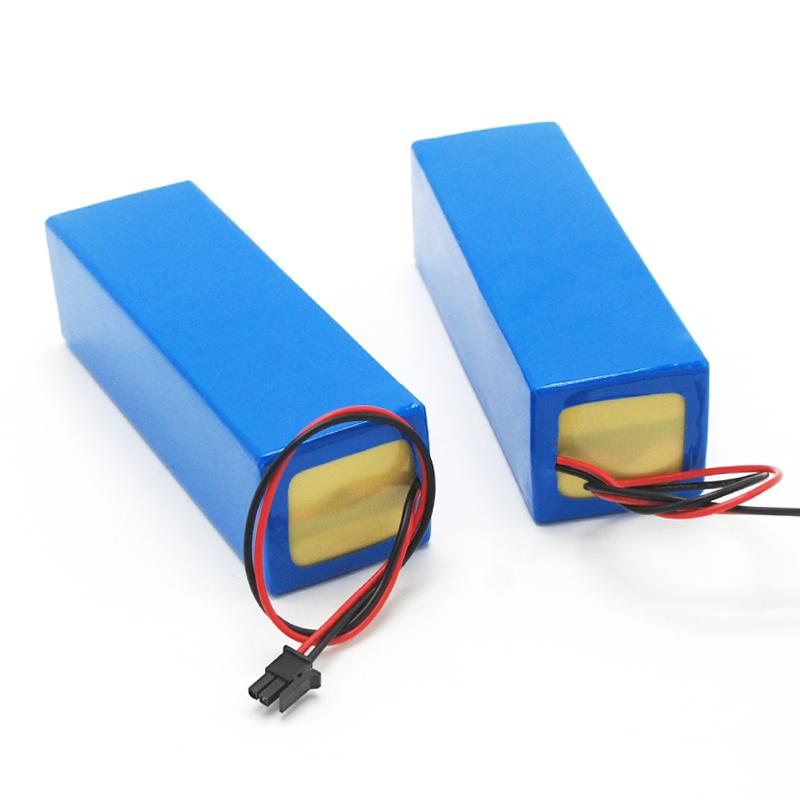

At Himax, every lithium battery pack we ship is pre-charged to a safe storage level to ensure long-term stability during transport and inventory periods.

Recommended Temperature and Environment

Temperature is one of the biggest factors affecting lithium battery health.

Best storage temperature:

15°C to 25°C (59°F to 77°F) — cool, dry, and stable.

Avoid:

High heat (>40°C / 104°F): Accelerates chemical aging and gas generation.

Freezing conditions (<0°C / 32°F): Can cause lithium plating inside the cell.

High humidity: Leads to corrosion and oxidation at battery terminals.

Store the battery in a clean, dry, and ventilated environment, away from direct sunlight or flammable materials.

Recharge Regularly During Storage

Even when disconnected, lithium batteries gradually lose charge due to self-discharge and BMS standby current.

If the battery is stored too long without recharging, voltage can drop below the safety threshold and cause over-discharge.

To avoid this:

Recharge the battery every 3 months to maintain proper voltage.

Use a charger designed for your specific battery type and voltage.

For long-term storage, enable the sleep mode or shipping mode if your BMS supports it.

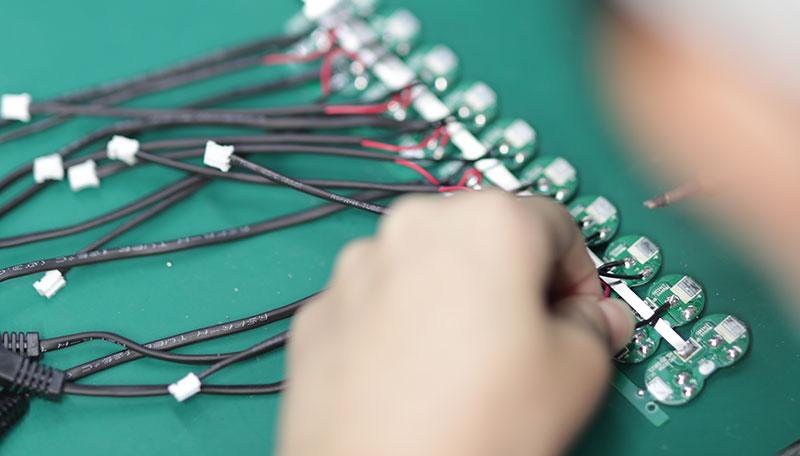

At Shenzhen Himax Electronics Co., Ltd., our smart BMS designs include low self-consumption circuits and optional sleep functions to protect batteries during long storage or transport.

Storage Tips for Different Applications

For Individual Users:

Disconnect the battery from your device when not in use.

Keep it in a cool drawer or cabinet — not inside a hot vehicle.

For Industrial or OEM Users:

Store battery packs in a controlled warehouse environment.

Place batteries on insulated shelves (not directly on concrete floors).

Record the storage date and periodically check voltage.

For Large-Scale Projects:

Follow local safety regulations for lithium battery storage.

Avoid stacking heavy packs together to prevent mechanical stress.

Ensure fire safety equipment and ventilation are in place.

Summary of Storage Guidelines

| Factor | Recommended Condition | Why It Matters |

| State of Charge (SOC) | 50–60% | Prevents both overcharge and deep discharge |

| Temperature | 15°C–25°C | Reduces chemical aging |

| Humidity | <60% RH | Prevents corrosion |

| Recharging | Every 3 months | Maintains safe voltage |

| Environment | Cool, dry, ventilated | Ensures long-term safety and stability |

Final Thoughts

Proper storage is not complicated, but it makes all the difference between a battery that lasts for years and one that fails prematurely.

By keeping your lithium battery at the right charge level, in a cool and dry place, and recharging it periodically, you can maintain both performance and safety for the long term.

At Shenzhen Himax Electronics Co., Ltd., we specialize in manufacturing high-quality lithium-ion batteries and smart BMS systems designed for long-term stability and safety. Whether you need customized battery solutions for robotics, industrial equipment, or energy storage, our engineering team ensures your batteries stay reliable — even after months of storage.