In today’s industrial world, reliable and efficient power solutions are essential for smooth operations. Custom batteries play a critical role in providing power to various industrial applications, from machinery and devices to backup systems. However, selecting the right custom battery supplier can be a challenging task. This article will guide you through the key factors to consider when choosing a supplier for custom batteries that meet your specific industrial needs.

-

Introduction

Custom battery packs are essential in modern industrial applications, powering everything from machinery and devices to backup systems. As industries become more reliant on energy-efficient and sustainable solutions, the demand for customized battery solutions has never been higher.

For companies looking to integrate battery power into their operations, choosing the right custom battery supplier is crucial. The quality and reliability of your battery solution can directly impact your business operations, product efficiency, and overall cost-effectiveness. With so many suppliers available, selecting the right one can seem daunting. This article will provide insights on how to identify the best custom battery supplier for your specific needs.

-

Understanding Key Requirements for Industrial Battery Packs

Before selecting a custom battery supplier, it’s essential to understand the specific needs of your industrial application. These requirements will help you narrow down your options and ensure that you choose a supplier who can meet your expectations.

Application Diversity

Industrial applications vary significantly across different sectors. Some of the most common sectors that rely on custom battery solutions include:

-

Automation: Industries involved in automation, such as robotics and control systems, require batteries that deliver consistent power over long periods.

-

Internet of Things (IoT): IoT applications require batteries that provide long-lasting power while being compact and lightweight.

-

Medical Devices: Batteries used in medical equipment must be reliable, long-lasting, and safe to ensure patient safety.

-

Energy Storage: Renewable energy systems, such as solar or wind power, need batteries that store energy efficiently and discharge it when necessary.

Each of these sectors has its own unique requirements in terms of power output, battery life, and size. Understanding these needs thoroughly is crucial when choosing a custom battery pack.

Power Requirements and Battery Capacity

One of the most critical factors when selecting a battery is determining the power and capacity needed for your application. Custom battery packs are designed to meet specific power demands. Some key considerations include:

-

Power Output: How much power does your application need to function? Custom batteries can be tailored to meet the voltage and current requirements of your devices.

-

Battery Capacity: Battery capacity determines how long the battery can power your device before needing a recharge. Depending on your application, you may require a high-capacity battery for longer operating times or one that is easily rechargeable for frequent use.

A reliable custom battery supplier will help you find the ideal balance between power output and capacity for your application.

Environmental Durability and Performance

Industrial environments can be harsh, so the batteries used must withstand various conditions. Here are some factors to consider:

-

Temperature Extremes: Batteries must perform well in both high and low temperatures. For example, outdoor equipment or machinery exposed to extreme weather conditions requires a battery that can handle temperature fluctuations.

-

Moisture Resistance: For applications in humid or wet environments, moisture resistance is vital. Custom battery suppliers should offer solutions that are resistant to water or condensation exposure.

-

Shock and Vibration: In industries where equipment undergoes vibrations or impacts, choosing a battery that can withstand physical stress is essential.

A good custom battery supplier will ensure their products meet these environmental requirements.

-

Key Factors in Choosing a Custom Battery Supplier

Selecting the right supplier for custom batteries involves several crucial considerations. Here are some of the most important factors to keep in mind:

Technical and Research Capabilities

The ability to customize battery packs for your specific needs is essential. Look for a supplier with strong technical expertise and a dedicated research and development (R&D) department that can collaborate with you to design the ideal custom battery. A supplier with a focus on innovation will help you address the unique challenges of your application and stay ahead of industry trends.

Battery Technology and Innovation

Not all batteries are the same. Different battery technologies offer distinct advantages depending on the application. Common technologies include:

-

Lithium-Ion Batteries: Known for their high energy density, lithium-ion batteries are widely used in industrial applications because of their compact size, long cycle life, and high efficiency.

-

Lead-Acid Batteries: These are often more cost-effective for applications where size and weight are not as critical. They are commonly used in backup power systems.

-

Solid-State Batteries: Solid-state batteries are emerging in the market and offer higher energy density and safety compared to traditional lithium-ion batteries.

A supplier should offer various options and help you choose the best battery technology for your application.

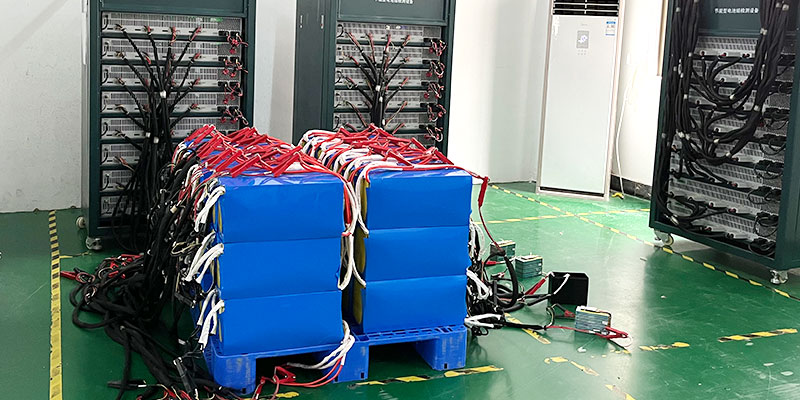

Manufacturing Capacity and Quality Control

Your custom battery supplier must have the necessary manufacturing capacity to meet your order size. Whether you need a small batch or large-scale production, the supplier should be able to handle your requirements. Additionally, robust quality control is crucial to ensure that the batteries meet the highest standards. Look for certifications such as ISO, UL, or CE to confirm that the supplier follows strict manufacturing processes and produces high-quality products.

Certifications and Standards

Ensure that the supplier complies with industry certifications and safety standards. These certifications, such as ISO 9001 (quality management), UL (Underwriters Laboratories), and CE (European Conformity), indicate that the supplier follows stringent manufacturing processes and produces reliable, safe products.

After-Sales Service and Support

After-sales service is often overlooked but is a critical component of a successful supplier relationship. Ensure that your supplier offers:

-

Warranty and Replacement Services: In case of battery failures or defects, the supplier should offer a clear warranty policy and provide replacements or repairs when necessary.

-

Technical Support and Training: Some applications may require ongoing technical support. Suppliers should offer training and troubleshooting assistance to your team.

-

Supply Chain Management: Reliable delivery timelines and inventory management are essential. Ensure that the supplier has the capacity to deliver on time and manage your inventory needs.

-

How to Evaluate and Choose the Right Custom Battery Supplier

Evaluating potential custom battery suppliers involves several steps. Here are some guidelines to consider when making your decision:

Compare Supplier Technical Capabilities and Product Performance

When selecting a supplier, focus on their technical expertise and product performance. Look for a supplier with experience in creating batteries for your specific application. Request samples to evaluate the performance and reliability of their batteries. Ensure that the battery’s power output, lifespan, and durability meet your operational needs.

Evaluate Customer Feedback and Reputation

The reputation of a supplier speaks volumes about the quality of their products and customer service. Look for online reviews, case studies, and testimonials from customers in your industry. Reputable suppliers will have positive feedback from clients who have successfully used their custom batteries.

Consider the Supplier’s Cost-Effectiveness

While price should not be the only consideration, it is still an important factor. Compare prices among different suppliers to ensure you are getting the best value for your investment. Keep in mind that the cheapest option may not always provide the best quality or long-term value.

-

HIMAX Electronics: Your Partner in Custom Battery Solutions

HIMAX Electronics is a trusted name in the custom battery industry, with years of experience providing tailored battery solutions. With a commitment to innovation and quality, HIMAX offers custom battery solutions that meet the unique needs of various industries. Their expertise in lithium-ion technology and other cutting-edge battery solutions makes them a top choice for industrial applications.

HIMAX stands out because of its:

-

High-Quality Manufacturing: HIMAX’s batteries are manufactured using state-of-the-art technology, ensuring performance, safety, and longevity.

-

Tailored Solutions: Whether you need a small battery pack for a portable device or a large energy storage system, HIMAX offers customized solutions designed to meet your exact specifications.

-

Global Reach: With a strong global presence, HIMAX collaborates with clients worldwide, providing reliable delivery and excellent customer service.

HIMAX’s commitment to continuous innovation and customer satisfaction makes it a leading choice for businesses seeking reliable, high-performance custom batteries.

-

Conclusion and Recommendations

Choosing the right custom battery supplier is critical to the success of your industrial application. It is essential to evaluate the supplier’s technical capabilities, manufacturing processes, product performance, and customer service.

When selecting a supplier, focus on the specific needs of your application and ensure that the supplier offers customized solutions to meet those needs. HIMAX Electronics offers a range of custom battery solutions designed to enhance your business operations. With their commitment to quality and innovation, HIMAX is a reliable partner for your custom battery needs.