Lithium composite material enhances performance and safety of next-gen lithium rechargeable batteries

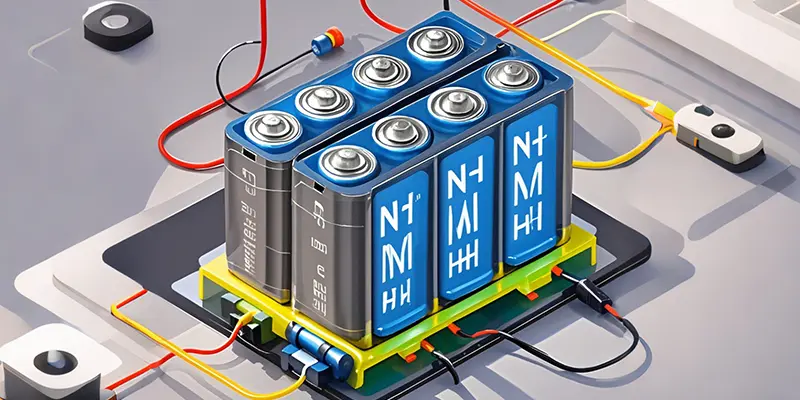

The process involves mechanically kneading lithium foil and LLZO particles. The LLZO particles are placed on top of the lithium foil, which is then folded in half and pressed flat using a roll press. This folding and pressing cycle is repeated multiple times (the research team repeated it 30 times) to create a composite material in which the lithium and LLZO particles are evenly mixed. Credit: Korea Research Institute of Chemical Technology (KRICT)

Amid the global pursuit of next-generation secondary battery solutions to replace current lithium-ion technology, Korean researchers have pioneered a lithium composite material that dramatically enhances both safety and lifespan, achieving over three times longer durability compared to existing materials.

The research team, led by Dr. Do-Yeob Kim from the Korea Research Institute of Chemical Technology (KRICT), has unveiled a novel lithium composite that stabilizes lithium growth, effectively overcoming the uncontrolled growth of lithium metal within batteries, which historically has impaired performance and safety.

The findings are published in the journal Advanced Functional Materials.

This high-stability lithium composite material is poised to significantly advance the development of lithium-metal, lithium-sulfur, and lithium-air batteries. By suppressing dendritic lithium growth, a common barrier to the development of safe and high-performance batteries, this new composite addresses one of the most critical challenges in next-generation battery technology.

Currently, graphite is the dominant primary anode material in lithium-ion batteries due to its affordability and safety. However, given graphite’s lower energy density and limited capacity, lithium metal is an ideal alternative for the anodes in next-generation lithium batteries.

Unlike conventional lithium-ion batteries, which rely on a stable graphite structure to store lithium ions, lithium-metal batteries accumulate lithium directly on the metal surface, resulting in “lithium dendrites.” These dendrites can reduce battery efficiency, compromise safety, and in severe cases, lead to short circuits and battery explosions.

Sample print obtained from resin with a) conventional, non-functional crosslinker and b) HABI crosslinker. c) Magnified image obtained using optical microscopy. Credit: Korea Research Institute of Chemical Technology (KRICT)

Dr. Kim’s team has introduced a lithium composite material that promotes uniform lithium growth while facilitating ion transport. The composite was fabricated using an innovative method that involves physically blending lithium with an electrolyte material (Al-doped Li7La3Zr2O12 [Al-LLZO]), rather than relying on high-temperature processing.

Testing confirmed that the composite material not only reduced dendritic growth but also extended battery life by more than three-fold compared to traditional lithium metal, demonstrating stable performance over 250 charge-discharge cycles without significant capacity loss. Additionally, charging speeds increased by more than 20% under specific conditions.