How to Choose the Right NiMH Battery Pack for Industrial Applications

Introduction

In industrial settings, where reliable power sources are critical, selecting the right battery can make a significant difference in performance and cost-efficiency. Among the many options available, nickel-metal hydride (NiMH) batteries stand out as a versatile and reliable choice for industrial use. In this blog, we’ll guide you through the essential factors to consider when choosing the Ni-Mh Battery for industrial applications, ensuring you make an informed decision that meets your operational needs.

Understanding NiMH Batteries

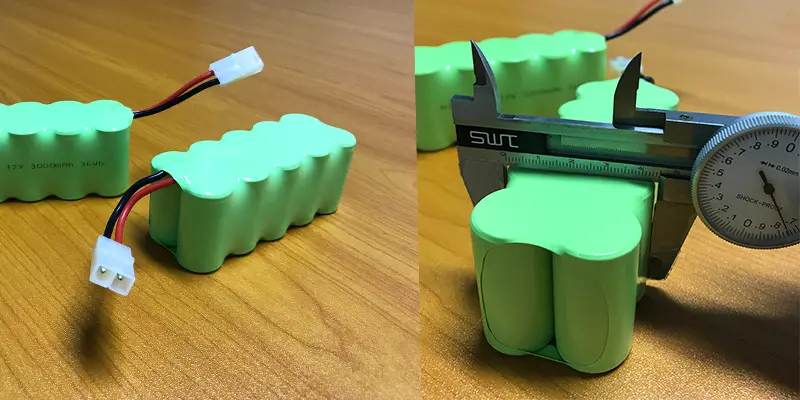

What are NiMH Batteries? NiMH batteries are rechargeable batteries that use a nickel oxide hydroxide (NiOOH) cathode and a hydrogen-absorbing alloy anode. Known for their high energy density and environmental benefits, NiMH batteries have become a preferred choice for many industrial applications.

Key Features:

· High energy density compared to NiCd batteries.

· Environmentally friendly with no toxic cadmium.

· Rechargeable with a long service life.

Comparison with Other Battery Types: While lithium-ion batteries offer higher energy density, NiMH batteries are often favored for their safety, cost-effectiveness, and stable performance in high-drain devices. Compared to NiCd batteries, NiMH offers better energy capacity and is more eco-friendly.

Factors to Consider When Choosing an NiMH Battery for Industrial Use

Application Requirements

Determine the energy needs of your equipment: Is it high-drain or low-drain?

Assess the size and form factor required to ensure compatibility with your devices.

Operating Conditions

Ensure the battery can operate within your environment’s temperature range.

Look for batteries with strong resistance to vibration and shock, especially for heavy-duty applications.

Cycle Life and Longevity

Prioritize batteries with a longer cycle life to reduce maintenance and replacement costs.

Customization Options

Consider working with a manufacturer like Himax that offers custom-designed battery packs tailored to specific industrial needs.

Common Industrial Applications of NiMH Batteries

· Robotics: Powering autonomous systems, portable machines, and industrial robots.

· Medical Equipment: Providing reliable energy for critical devices such as infusion pumps and portable diagnostic tools.

· Renewable Energy Systems: Acting as backup power for solar and wind energy systems.

· Communication Devices: Supporting industrial radios and wireless communication tools in remote environments.

Advantages of NiMH Batteries for Industrial Applications

-

Eco-Friendly: NiMH batteries do not contain toxic materials like cadmium, making them safer for the environment.

-

Cost-Effectiveness: Despite a slightly higher initial cost, their long-term savings in reduced maintenance and replacements make them a cost-effective choice.

-

Safety: NiMH batteries have a lower risk of thermal runaway compared to lithium-ion batteries.

-

High Performance: They provide stable voltage and reliable energy delivery, even under high-drain conditions.

Tips for Maintaining and Maximizing NiMH Battery Performance

· Proper Charging Techniques: Use chargers specifically designed for NiMH batteries to avoid overcharging.

· Storage Best Practices: Store batteries in a cool, dry place to prevent degradation.

· Regular Maintenance: Periodically test and balance the batteries to ensure optimal performance.

· Replacement Indicators: Monitor performance and replace batteries showing significant capacity loss.

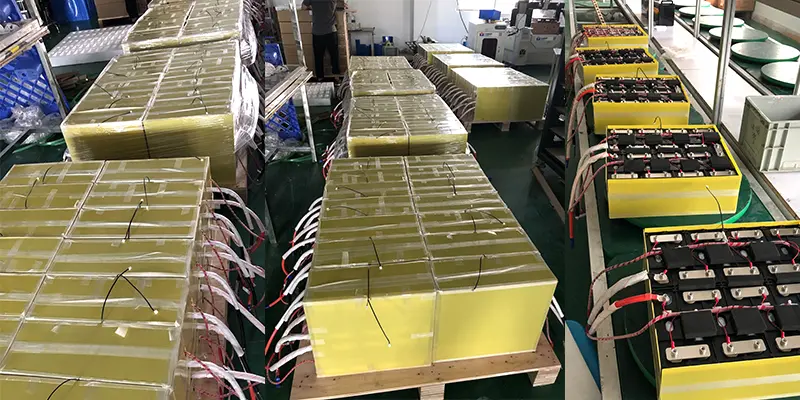

Why Himax is Your Partner for NiMH Batteries

With over 18 years of experience in battery production, Himax Battery is a trusted partner for industrial-grade NiMH battery solutions. Here’s why industrial buyers choose us:

· Expertise: Our team specializes in designing batteries for diverse industrial applications.

· Customization: We offer tailored NiMH battery packs to meet specific industrial requirements.

· Free Samples and Quality Assurance: Evaluate our batteries risk-free before bulk procurement.

· Global Reach: Reliable supply chains in Europe, the U.S., and beyond.

· After-Sales Support: Dedicated to ensuring customer satisfaction with comprehensive support.

Conclusion

Selecting the right NiMH battery pack for industrial applications is essential for optimizing performance, reducing costs, and ensuring operational efficiency. By understanding your application requirements and considering factors like cycle life, operating conditions, and customization options, you can make an informed choice. Contact Himax today to explore our tailored NiMH battery solutions or request a free sample to get started.