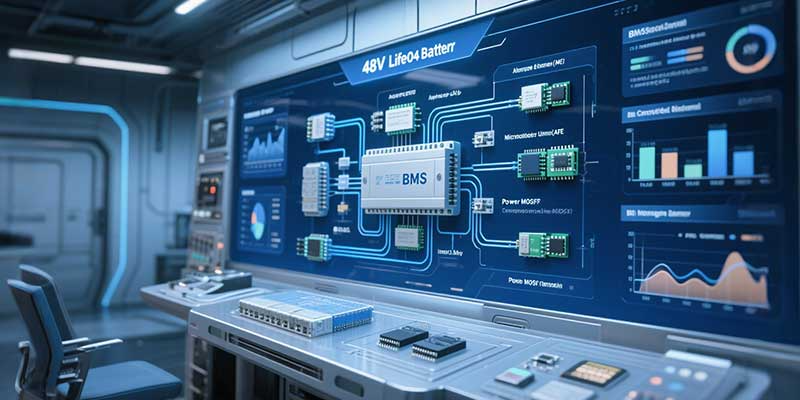

In every modern lithium-ion battery pack, the Battery Management System (BMS) plays a vital role. It protects the cells, balances voltages, and ensures safe operation.

However, one common issue often overlooked is that the BMS itself can consume power from the battery, and if left unchecked for long periods, this can lead to over-discharge — even when the pack is not in use.

At Shenzhen Himax Electronics Co., Ltd., we often explain this phenomenon to customers who are surprised to find that their battery voltage drops over time despite no external load connected. Understanding why this happens helps prevent premature cell damage and extends battery life.

1. The BMS Always Draws a Small Standby Current

Even when a battery pack is “off,” the BMS remains partially active. It continuously monitors parameters such as:

Cell voltage and temperature

State of charge (SOC)

Balance circuit status

To perform these functions, the BMS consumes a small quiescent current, usually in the range of tens to hundreds of microamps for low-power systems, and sometimes several milliamps in smart BMS designs with Bluetooth, RS485, or UART communication.

Over days or weeks, this constant drain can slowly discharge the cells. If the pack is stored for several months without recharging, the self-consumption current from the BMS alone can push the battery below its safe voltage limit.

2. How BMS Power Consumption Leads to Over-Discharge

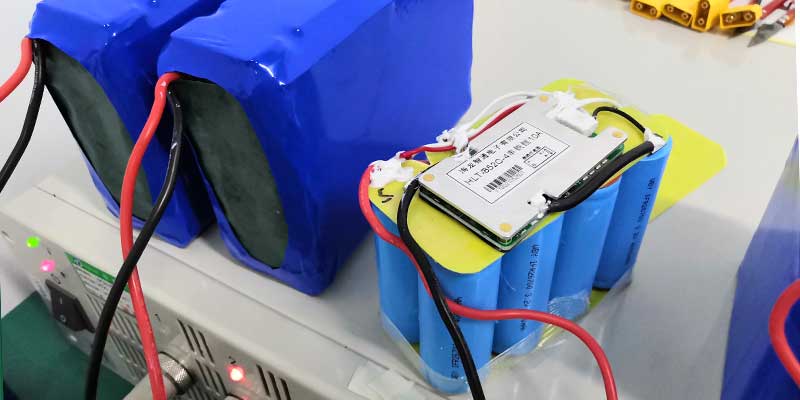

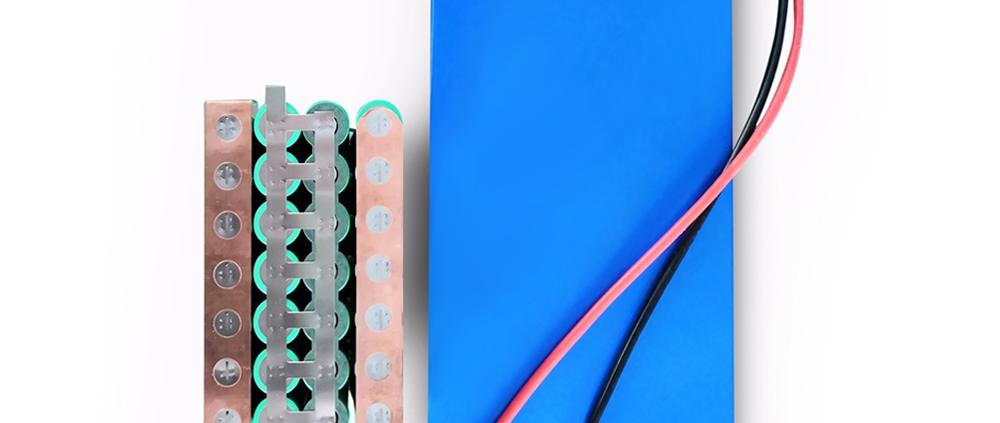

(1) Unbalanced Discharge Between Cells

In multi-cell packs, each cell’s voltage can drop slightly differently. The BMS monitors and balances them using small resistors or circuits that bleed current from higher-voltage cells.

During long storage, this balancing current can continue working, drawing more power from specific cells and leading to cell imbalance or deep discharge on some cells.

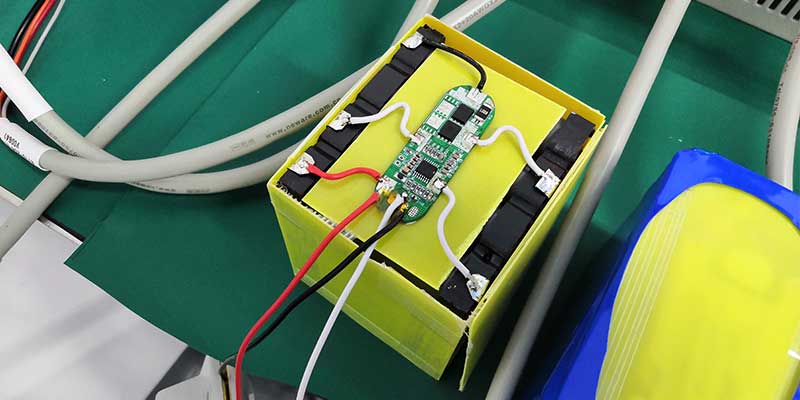

(2) Continuous Operation of Communication or Protection Circuits

Smart BMS modules — such as those used by Himax — often include communication interfaces (Bluetooth, CAN, UART, etc.). When these functions stay active, they require a small but constant current from the battery.

If the pack is not recharged for a long time, that continuous draw can discharge the pack below 2.5V per cell — a critical point that can permanently damage lithium cells.

(3) Storage Without Periodic Maintenance

If a battery pack is stored for months without being topped up, the combination of BMS self-consumption and natural self-discharge of the cells can cause total pack voltage to fall dangerously low.

Once over-discharged, the cells’ internal chemistry changes — copper dissolves, SEI layers break down — making the pack unstable and unsafe for reuse.

3. Real-World Example

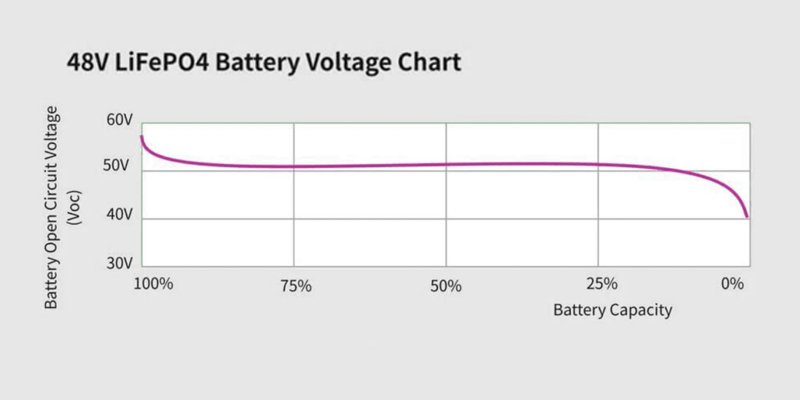

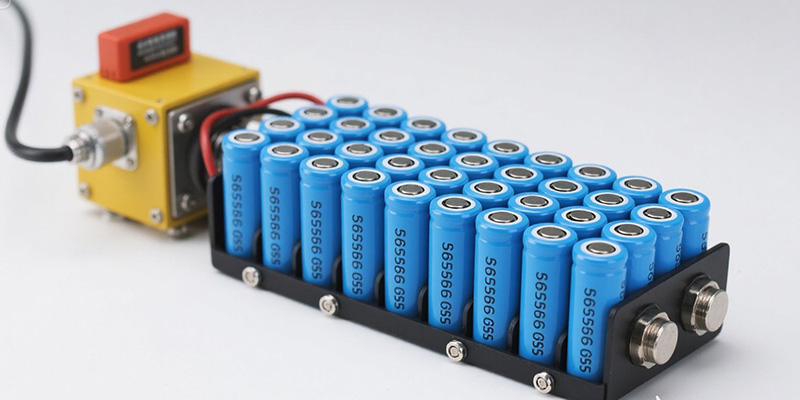

For instance, consider a 14.8V (4S) 20Ah lithium-ion battery pack with a smart BMS that consumes around 1mA in standby mode.

1mA over 90 days equals:

1mA × 24h × 90 ≈ 2.16Ah

That’s roughly 10% of the pack’s capacity lost simply to BMS self-consumption — not counting cell self-discharge. If stored too long, the voltage can easily fall below 3.0V per cell, triggering over-discharge.

4. How to Prevent BMS-Related Over-Discharge

To ensure your battery pack remains healthy during storage or transport, Shenzhen Himax Electronics Co., Ltd. recommends the following practices:

Recharge before storage

Charge the pack to around 50–60% SOC before long-term storage.

Disconnect or switch off the BMS

Some Himax smart BMS models include a sleep or shipping mode that fully disconnects the cells from the control board.

Recharge every 3–6 months

Regular maintenance charging keeps cell voltage above the safe threshold.

Use low self-consumption BMS

Choose a BMS with low quiescent current (<50μA) for applications where long idle time is expected. Himax engineers can help customize such designs.

Monitor remotely (optional)

For smart systems, use remote voltage monitoring to detect early voltage drops before the pack reaches an unsafe level.

5.Summary

| Cause | Effect | Solution |

| BMS standby current | Gradual voltage drop | Use low self-consumption BMS |

| Continuous balancing | Uneven discharge | Enable auto-sleep or cutoff |

| Smart features active | Faster drain | Disable communication during storage |

| Long-term storage | Deep over-discharge | Recharge every few months |

Final Thoughts

A BMS is essential for safety, but it is not completely power-free. Without proper maintenance, even a small standby current can slowly drain the battery pack and cause over-discharge damage.

At Shenzhen Himax Electronics Co., Ltd., we design and manufacture lithium battery packs with intelligent, energy-efficient BMS solutions that minimize self-consumption and protect against deep discharge. Our engineering team can help you select the right configuration or customize a smart BMS that matches your application perfectly — from robotics and industrial systems to energy storage and portable equipment.