Introduction

Lithium-ion batteries play a critical role in modern technology and industrial applications. From electric vehicles to medical devices, these batteries provide reliable power for a wide range of industries. As technology advances, businesses need more efficient and specialized power solutions to meet their operational demands.

The B2B (business-to-business) market is shifting towards customized solutions, and the battery industry is no exception. Standard battery packs often fail to meet the specific needs of businesses, leading to inefficiencies and performance issues. This is where custom lithium-ion battery packs come into play. These tailored power solutions offer flexibility, efficiency, and improved performance, making them the preferred choice for B2B buyers.

Why B2B Buyers Choose Custom Lithium-Ion Battery Packs

Flexible Specifications and Design

Every business has unique energy requirements. Standard battery packs may not provide the optimal power, size, or lifespan needed for specific applications. Custom lithium-ion battery packs allow businesses to tailor specifications such as voltage, capacity, dimensions, and discharge rates to suit their needs. This flexibility ensures seamless integration with different products and systems.

Enhanced Product Competitiveness

Businesses constantly seek ways to differentiate their products in competitive markets. Custom battery packs provide a competitive edge by offering improved performance and unique features. Whether it’s extending battery life for a portable device or optimizing power output for an industrial machine, a well-designed custom battery solution can enhance product value and market appeal.

Reduced Supply Chain Risks

Supply chain disruptions can significantly impact business operations. Off-the-shelf battery packs may face shortages, compatibility issues, or inconsistent quality. Custom battery solutions offer a more controlled and reliable supply chain. By working with a trusted battery manufacturer, businesses can ensure consistent quality, on-time delivery, and long-term availability.

Lower Long-Term Costs

While custom battery packs may have higher initial costs than standard options, they offer significant long-term savings. Customization helps reduce energy waste, improve efficiency, and extend battery life. This minimizes replacement and maintenance costs, leading to lower total ownership costs over time.

Meeting Industry-Specific Requirements

Different industries have unique power requirements that standard battery packs may not fulfill. Custom lithium-ion batteries can be designed to meet stringent safety, reliability, and performance standards. This is especially important for industries like:

-

Renewable Energy – Solar energy storage solutions require optimized battery management for efficient power usage.

-

Medical Devices – Healthcare equipment demands highly reliable, compact, and long-lasting battery packs.

-

Drones and Robotics – These technologies require lightweight yet powerful batteries with high energy density and fast charging capabilities.

Applications of Custom Lithium-Ion Battery Packs in Various Industries

Electric Vehicles (EVs)

Electric vehicle manufacturers need high-capacity, durable, and energy-efficient battery solutions. Custom lithium-ion battery packs allow EV companies to optimize energy storage, enhance battery lifespan, and improve safety. Customization also enables manufacturers to design batteries that fit within unique vehicle models and chassis configurations.

Wearable Devices

Wearable electronics, such as smartwatches and medical monitoring devices, require small, lightweight, and long-lasting batteries. Custom lithium-ion battery packs provide optimized energy storage while maintaining compact designs, ensuring better user experience and device efficiency.

Industrial Automation and Robotics

Robotic systems in manufacturing, logistics, and automation rely on reliable battery solutions for uninterrupted operation. Custom batteries provide the necessary power output, charge cycles, and durability needed for high-performance industrial applications.

Medical Equipment

Medical devices such as portable oxygen concentrators, infusion pumps, and defibrillators require precise and dependable power sources. Custom battery packs ensure safety, reliability, and compliance with medical industry regulations, helping healthcare providers deliver better patient care.

HIMAX Electronics: Your Trusted Custom Battery Solution Provider

About HIMAX Electronics

HIMAX Electronics is a leading provider of high-quality custom lithium-ion battery packs designed to meet the diverse needs of B2B clients. With years of experience in battery manufacturing and innovation, HIMAX Electronics delivers advanced power solutions tailored for various industries.

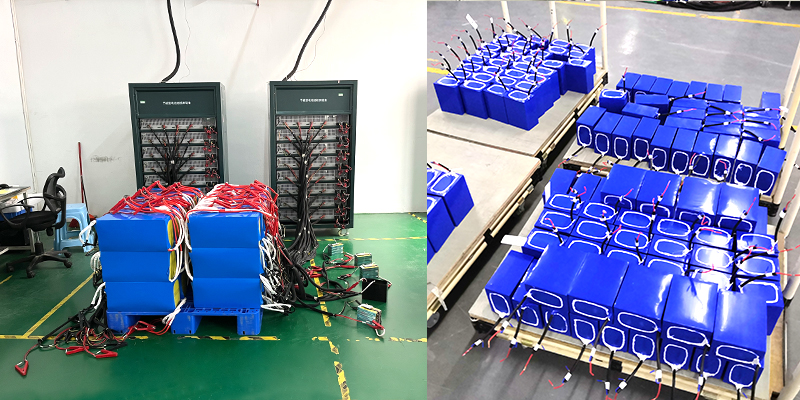

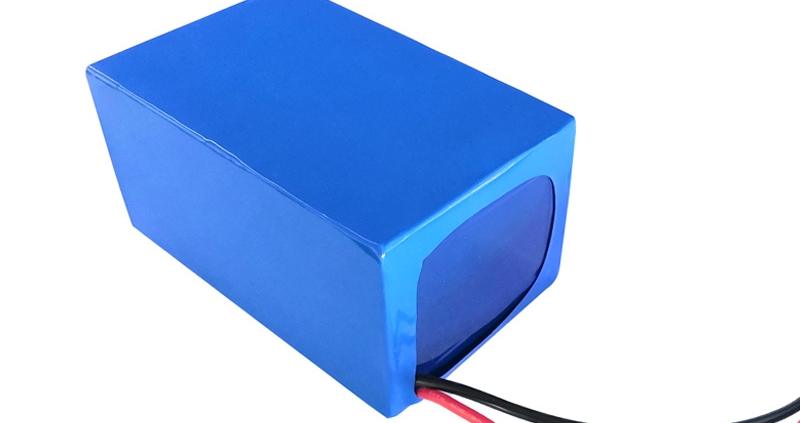

Comprehensive Customization Services

HIMAX Electronics offers fully customized battery packs with a wide range of specifications. Businesses can choose from various voltages, capacities, discharge rates, and form factors to create the perfect power solution for their products.

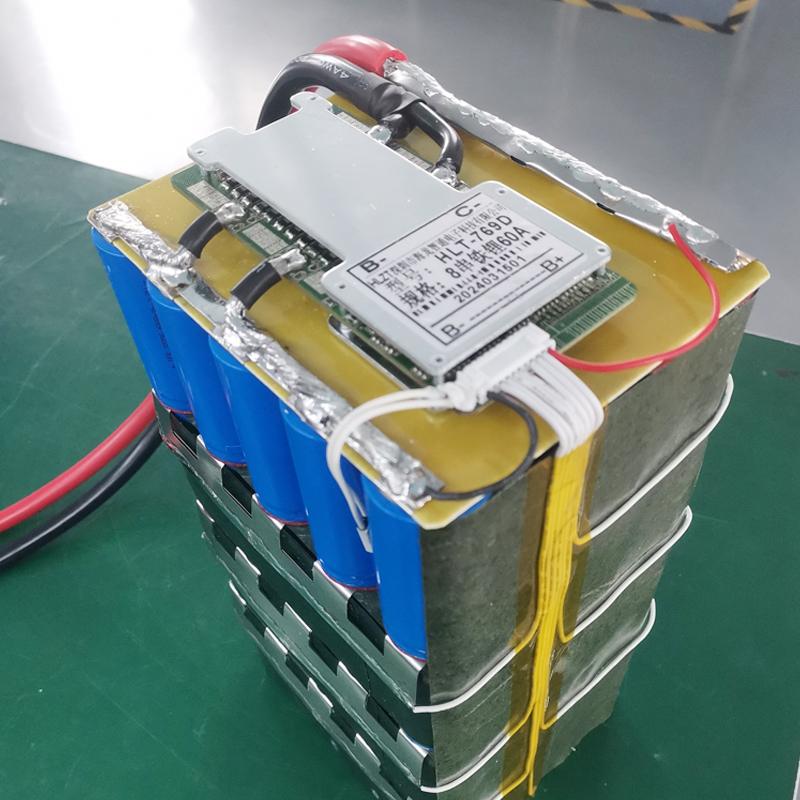

Cutting-edge technology and Quality Assurance

Quality and innovation are at the core of HIMAX Electronics’ solutions. Our advanced battery management systems (BMS) ensure optimal performance, safety, and longevity. Each battery pack undergoes rigorous testing to meet international safety and performance standards, ensuring reliability in every application.

Global Reach and Industry Applications

HIMAX Electronics serves businesses worldwide, providing battery solutions for electric vehicles, industrial automation, medical devices, and wearable electronics. Our global distribution network and excellent customer support make us the preferred partner for businesses seeking reliable custom battery solutions.

Conclusion

The demand for custom lithium-ion battery packs in the B2B market is skyrocketing. Businesses need efficient, reliable, and tailored power solutions to enhance their products and streamline operations. Custom batteries offer flexibility, cost savings, and industry-specific advantages that standard options cannot match.

HIMAX Electronics is committed to providing high-performance, customized battery solutions to help businesses succeed. Contact us today to explore our custom lithium-ion battery options and discover how we can power your innovations.