Understanding Outdoor Camera Backup Batteries

How Long Does an Outdoor Camera Battery Last?

One of the top concerns for users is the outdoor camera battery lifespan, which depends on several factors. First, battery capacity—measured in mAh—plays a big role. The higher the capacity, the longer it lasts. For example, a 2000mAh battery in standard shooting mode can typically snap 300-400 photos or record 1-2 hours of HD video. Second, your shooting mode matters. Recording 4K video or using live view drains power much faster than still photography. Also, environmental temperature affects outdoor shooting battery life. In cold conditions, battery performance can drop by 20%-30%. For instance, at 14°F (-10°C) in snowy conditions, a battery might last only 1.5 hours instead of 2. To handle harsh outdoor climates, prioritize batteries designed to withstand low temperatures, ensuring your backup battery usage time meets your shooting demands.

What Types of Batteries Do Outdoor Cameras Use?

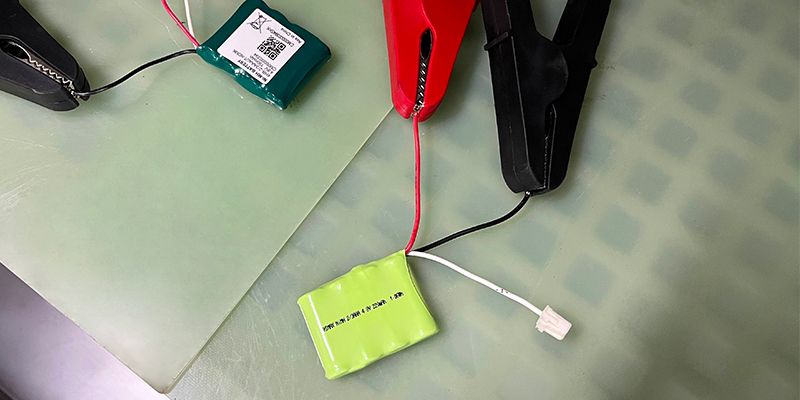

Knowing the outdoor camera battery types is the first step to choosing a backup battery. The most common types for outdoor cameras are lithium-ion batteries and V-Mount batteries. Lithium-ion batteries are the go-to choice due to their lightweight design (usually 100-300g) and high capacity (2000mAh or more), making them ideal for mobile outdoor shoots like hiking or wildlife photography. On the other hand, V-Mount batteries are better suited for professional setups, often used in filmmaking or long stationary shoots. They offer larger capacities (up to 10,000mAh) but are heavier (over 2 lbs), which can be a hassle if you need to stay light on your feet.

For outdoor practicality, lightweight lithium-ion batteries are the way to go. They’re easy to carry and often support fast charging, perfect for the flexibility needed in mobile shooting. Some lithium-ion batteries even come with smart power indicators, so you can keep tabs on remaining charge and avoid unexpected power cuts during a shoot.

Does the Battery Affect Your Outdoor Camera’s Performance?

While the outdoor camera shooting performance isn’t directly tied to the battery, its quality can indirectly impact your experience. Low battery levels can cause your camera to shut off unexpectedly, disrupting your shoot. For example, if you’re filming a time-lapse or a long video shot and the battery dies, you’ll lose your footage and miss critical moments. Additionally, battery quality affects power stability. A low-quality battery might deliver unstable voltage, causing your camera to glitch, resulting in shaky footage or random shutdowns. This is especially noticeable in high-demand modes like 4K video recording, where consistent voltage is crucial.

To avoid these issues, opt for a high-capacity, reliable battery to ensure stable, long-lasting performance. A quality stable power source not only extends your shooting time but also minimizes equipment failures, keeping your footage smooth and uninterrupted. While the battery’s impact on shooting isn’t direct, choosing the right one is key to a better outdoor shooting experience.

Practical Tips for Choosing an Outdoor Camera Backup Battery

In 2025, picking the right outdoor camera backup battery comes down to a few key considerations. Start with capacity. Go for a battery with at least 2000mAh to handle long shooting sessions. For instance, a 2200mAh battery can record about 2.5 hours of video or snap 500 photos, easily covering a full day of outdoor shooting. If you’re tackling heavy tasks like 4K video or time-lapses, consider a higher capacity, like 3000mAh or more.

Next, think about portability. Outdoor shoots often involve a lot of movement, so battery weight and size are crucial. Choose a lightweight option under 300g that fits easily into your backpack or pocket without adding bulk. Compact designs, like cylindrical or flat batteries, are great for storing alongside your camera gear.

Compatibility is another must. Before buying, double-check that the battery matches your camera model to avoid issues with fit or voltage. Batteries with fast-charging features are a bonus—some can charge to 80% in just 30 minutes, which is a lifesaver for quick recharges during outdoor shoots.

Finally, consider the rugged outdoor environment. Look for batteries that can handle low temperatures and resist shocks to withstand extreme weather and rough terrain. For example, in cold winter shoots, pick a battery that works at -4°F (-20°C). If you’re shooting in mountains or forests, opt for one with drop resistance to survive accidental falls. By factoring in these elements, you’ll ensure your outdoor shooting battery choice performs reliably in any scenario.

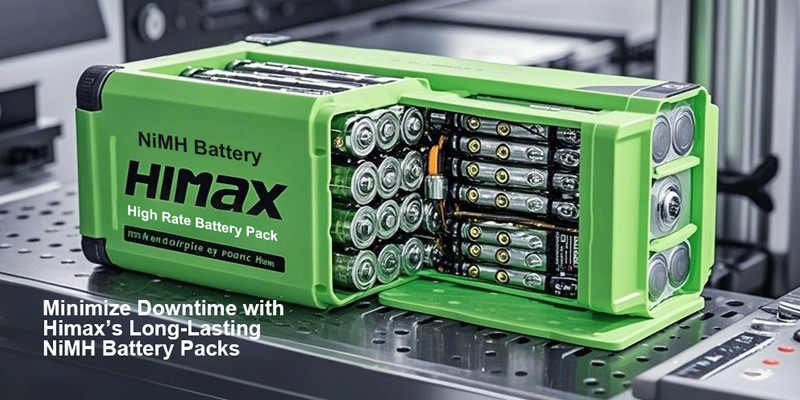

Why Choose HIMAX Outdoor Camera Backup Batteries?

If you’re looking for a high-performance outdoor camera backup battery, HIMAX Electronics has you covered. HIMAX outdoor camera backup batteries are built for outdoor shooting, boasting a 2200mAh capacity that supports up to 2.5 hours of video recording or 500 photos—perfect for a full day’s shoot. Weighing just 200g, they’re lightweight and feature cold-resistant technology, delivering stable power even at -4°F (-20°C). Compatible with various mainstream camera models, HIMAX batteries also offer fast charging, reaching 80% in 30 minutes to keep your shoot on track.