A Critical Path to Improving Li-ion Battery Pack Performance and Service Life

In Li-ion battery systems, poor consistency among cells is widely recognized as a core issue impacting the performance, safety, and lifespan of the entire battery pack. It not only limits the effective energy output but also introduces risks such as thermal runaway and uneven degradation during cycling.

This article analyzes poor consistency across multiple dimensions—capacity, internal resistance, voltage, self-discharge rate, and thermal response—and outlines the underlying causes and solutions to improve reliability and operational efficiency of Li-ion battery packs.

What Is Poor Li-ion Cell Consistency?

Poor Li-ion Cell consistency refers to significant variations in key electrical characteristics among Li-ion battery cells within the same pack or production batch. It is typically manifested in the following ways:

1. Capacity Inconsistency

When the rated or actual discharge capacity difference between cells exceeds ±3%, the performance of the entire Li-ion battery pack is limited by the weakest cell (the “barrel effect”), reducing usable capacity by up to 15%.

2. Internal Resistance Inconsistency

A ≥5% difference in internal resistance causes some cells to overheat during charge/discharge cycles, accelerating aging and triggering a vicious cycle:

higher resistance → higher temperature → further resistance increase.

3. Voltage Inconsistency

If the open-circuit voltage (OCV) deviation exceeds 0.05V, cells in series configurations are prone to imbalance—low-voltage cells may be over-discharged, and high-voltage cells overcharged, leading to cycle instability and safety concerns.

4. Self-Discharge Rate Differences

Variations in self-discharge rates cause SOC (state of charge) divergence after idle storage. The K-value (voltage drop over time) should be used to detect and screen out abnormal cells. Failure to do so increases pack inconsistency over time.

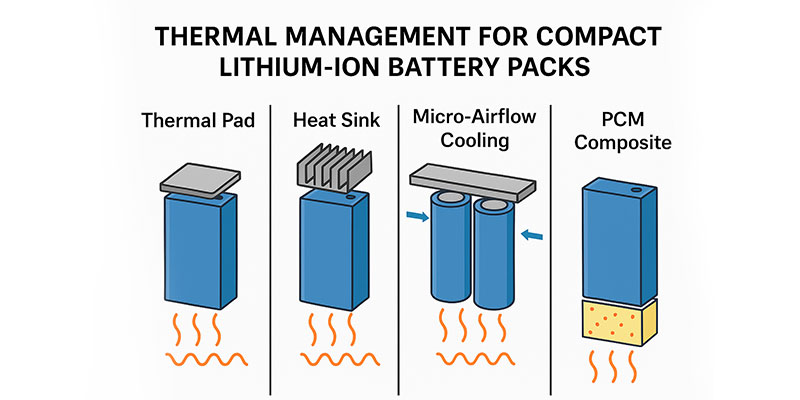

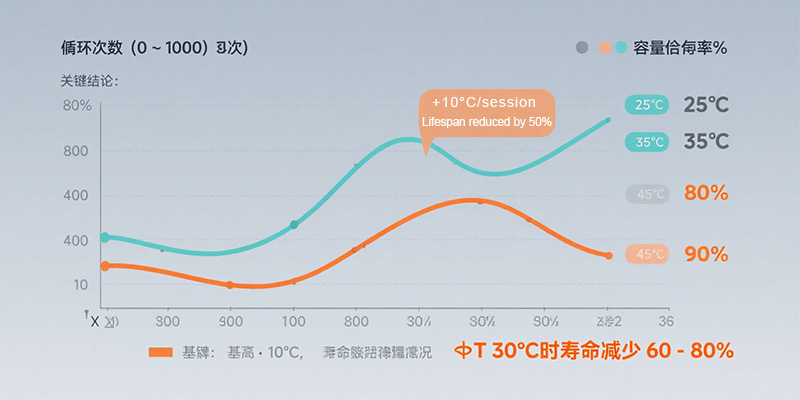

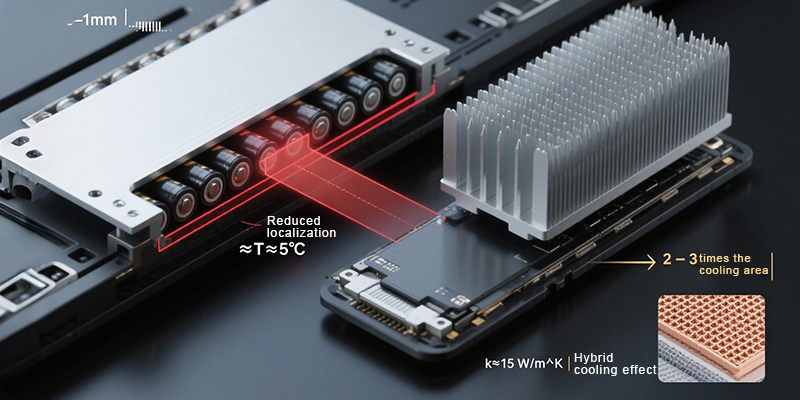

5. Thermal Response Inconsistency

If temperature differences between cells exceed 5°C during operation, localized hot spots may accelerate aging, widening performance disparities further.

Causes of Poor Li-ion Cell Consistency

1. Manufacturing Process Variations

Uneven slurry coating and variations in active material density

Inconsistent roll-pressing thickness

Errors in electrolyte injection or sealing processes

These factors result in initial inconsistencies in Li-ion battery cells at the production stage.

2. Amplification During Use

Small initial differences become magnified through charge/discharge cycles:

Lower-capacity cells are more prone to over-discharge, damaging active material

Higher-capacity cells may remain near overcharge conditions, increasing the risk of lithium plating

3. Safety and System-Level Impacts

Risks of localized lithium plating and thermal runaway increase significantly (see “Li-ion Battery Safety Issues and Failure Analysis”)

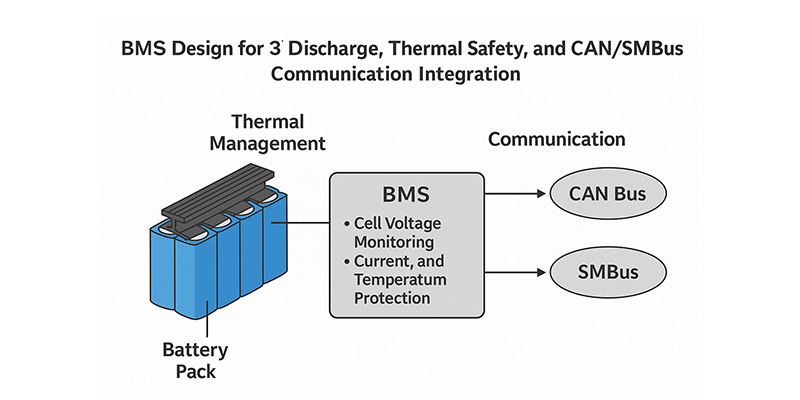

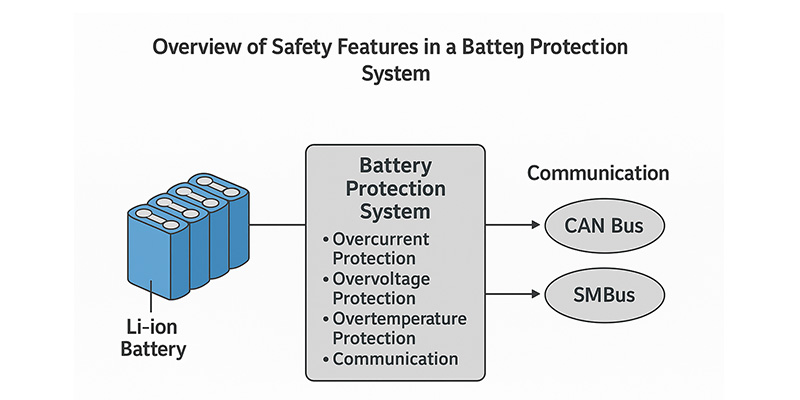

BMS (Battery Management System) balancing strategies cannot fully compensate for long-term physical differences between cells

Solutions to Improve Cell Consistency

Manufacturing-Side Improvements:

- Slurry Coating and Roll-Press Optimization:

Control electrode sheet density variation within ±1.5%to ensure uniform active material distribution. - Vacuum Drying Temperature Uniformity:

Maintain drying oven temperature deviation under 3°Cto ensure uniform electrolyte behavior and separator integrity. - Multi-Parameter Cell Sorting and Grouping:

Sort and assemble cells based on capacity, internal resistance, and voltage, ensuring matched characteristics before pack assembly.

Application-Side Improvements:

- Thermal Management at Module Level:

Keep temperature differences across modules within 5°Cto prevent uneven degradation. - Intelligent Balancing System:

Use active balancing strategies(e.g., energy transfer-based BMS) to dynamically equalize SOC across cells. - Routine Monitoring and Maintenance:

Continuously track internal resistance and voltage changes to detect and isolate underperforming cells early.

Final Thoughts: Consistency Is the Foundation of Battery System Safety

While not always a visible parameter, cell consistency is the underlying logic of long-term reliability in any Li-ion battery system. By combining precision-controlled manufacturing with real-time system-level balancing, manufacturers can significantly improve battery pack consistency, extend service life, and ensure safety under demanding conditions.

For high-performance Li-ion battery pack applications—such as energy storage systems (ESS), power tools, and medical devices—cell consistency is the critical factor that distinguishes a qualified product from an outstanding one.

Interested in our expertise in cell grading, automated consistency testing, or BMS balancing solutions?

Contact the HIMAX ELECTRONICS sales team for detailed documentation, product samples, or engineering consultation.