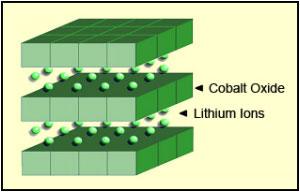

Advanced Li-ion battery

Fundamental degradation mechanism of Ni-rich layered cathodes on li ion customized battery packs

Increasing of the Ni fraction increase the discharge capacity of the cathode but decreases the ability to retain its original capacity during cycling. The relatively inferior cycling stability of NCM with x > 0.8 is attributed to the phase transition near the charge-end. Stress stemming from the H2 to H3 phase transition destabilized the internal microcracks and allowed the microcracks to propagate to the surface, providing channels for electrolyte penetration and subsequent degradation of the exposed internal surfaces.

Concentration gradient cathode materials for advanced li ion customized battery packs

NCM cathodes with concentration gradients represent a viable solution that simultaneously addresses the specific energy density, cycling and chemical stability, and safety issues of Ni-enriched NCM cathodes. Currently, concentration gradient cathode with extremely high Ni content has been developed by X-doping. Interdiffusion and coarsening in the X-doped CG cathode were suppressed by the segregation of X at the grain boundary and particle surfaces, which also provided a protective coating layer that lowered the surface reactivity.

Microstructurally modified cathodes by high valence electron elements doping

Specific dopants, especially high-valence elements can change the morphology of primary particles in Ni-rich cathode materials. The introduction of a high- valence element during calcination effectively reduces the size of the grains and refines the morphology of primary particles into rod-shaped ones by inhibiting the coarsening of particles. The superior cycling stability clearly indicates the importance of the particle microstructure (i.e., particle size, particle shape, and crystallographic orientation) in mitigating the abrupt internal strain caused by phase transitions in the deeply charged state, which occur in Ni-rich layered cathodes.

Effects of low valence elements excess doping in microstructure

The grain size refinement can be achieved by the introduction of an excess amount of Al doping, which inhibits particle coarsening by segregating Al ions at the particle boundaries. A highly aligned microstructure is achieved by doping 4 mol% of Al, which can allow uniform contraction of the primary particles in the deeply charged state, preventing the formation of local stress concentrations, and deflecting the propagation of microcracks. The proposed Al 4mol%-doped NCA cathode represents a new breed of a Ni-rich NCA cathode that can meet the energy density required for the next-generation EVs without compromising the battery life and safety.

Advanced Co-free cathode

The elimination of Co from Ni-rich layered cathodes is considered a priority to reduce their material cost and for sustainable development of li ion customized battery packs as Co is becoming increasingly scarce. In the Co-free cathode, the H2-H3 phase transition occurring near the charge end is shifted to a high voltage, so the capacity is lower than that of the NCM cathode at the standard operating voltage (4.3V). However, when operated at high voltage(4.4V), it shows improved thermal stability and cycling stability due to high Mn contents, while exhibiting capacity similar to that of NCM cathode.

Introducing High-Valence Elements into Co-free NM Cathodes(micro-, nano- structure enegineering)

By doping high-valence elements into the Co-free cathodes, the electrochemical performances of the cathodes can be further extended. The grain size refinement achieved by X-doping (X=high-valence element) dissipates the deleterious strain from abrupt lattice contraction through fracture toughening and the removal of local compositional inhomogeneities. Also, the unique structure induced by the presence of X stabilizes the delithiated structure through a pillar effect. The X-doped NM90 cathode can deliver a high capacity with cycling stability, and is suitable for the electric vehicles with long service life at a reduced material cost.

Source:

http://escml.hanyang.ac.kr/sub/sub01_02.php

If you have any question, please feel free to contact us:

- Name: Dawn Zeng (Director)

- E-mail address: sales@himaxelectronics.com